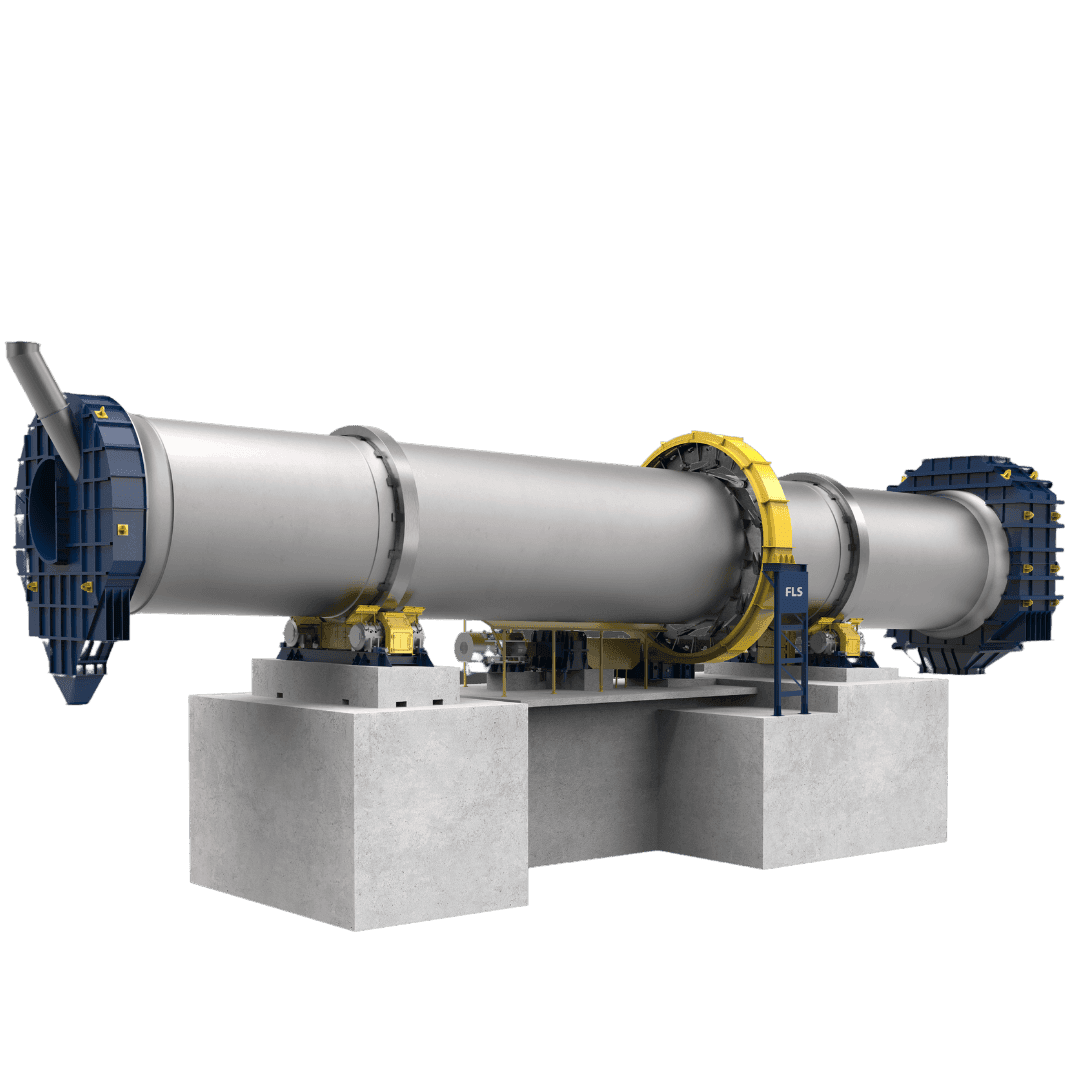

Our rotary dryers

We offer a standard range of rotary dryers with diameters between 3m and 6m and throughput of ≤5.0tph to ≥1,000tph in a single dryer. For applications that fall outside of these specifications, we provide custom solutions. Our rotary dryers can operate as stand-alone equipment or can be integrated with other equipment, such as mills, for a complete flowsheet solution.