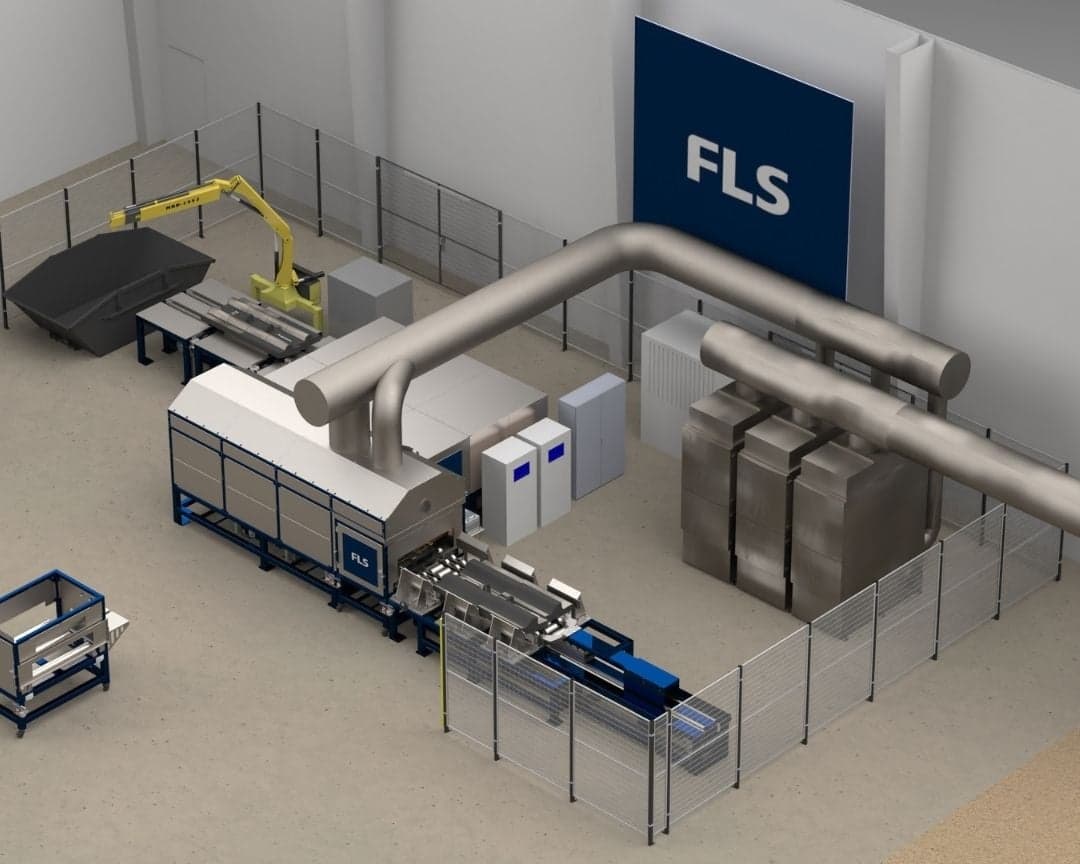

Mill liner recycling solutions

We have developed a comprehensive, yet seamless, recycling solution for composite, rubber and metallic grinding mill liners. Specifically for difficult recycling components like rubber and composite, we now have a proven mill liner recycling machine that can handle various liner types, shapes and sizes.

We are collaborating with local partners worldwide across the recycling value chain, including foundries handling steel liner recycling and several waste management companies. Currently, we are only offering this innovating solution to our customers located in South America. But we will be extending our capabilities across the world, starting with North America, soon.