Key features of FLS centrifuge consumables for mining processes

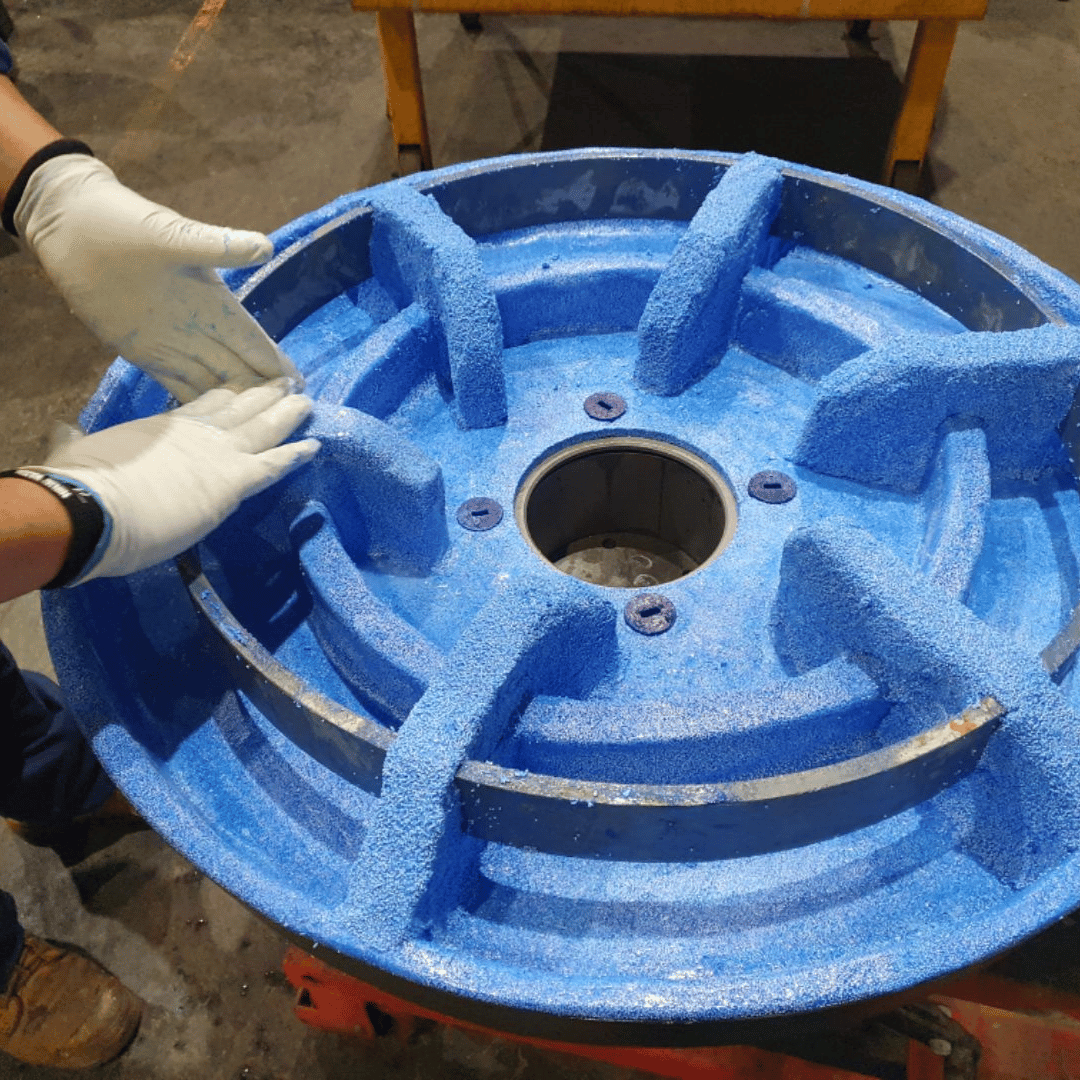

- High-grade materials for enhanced wear and corrosion resistance

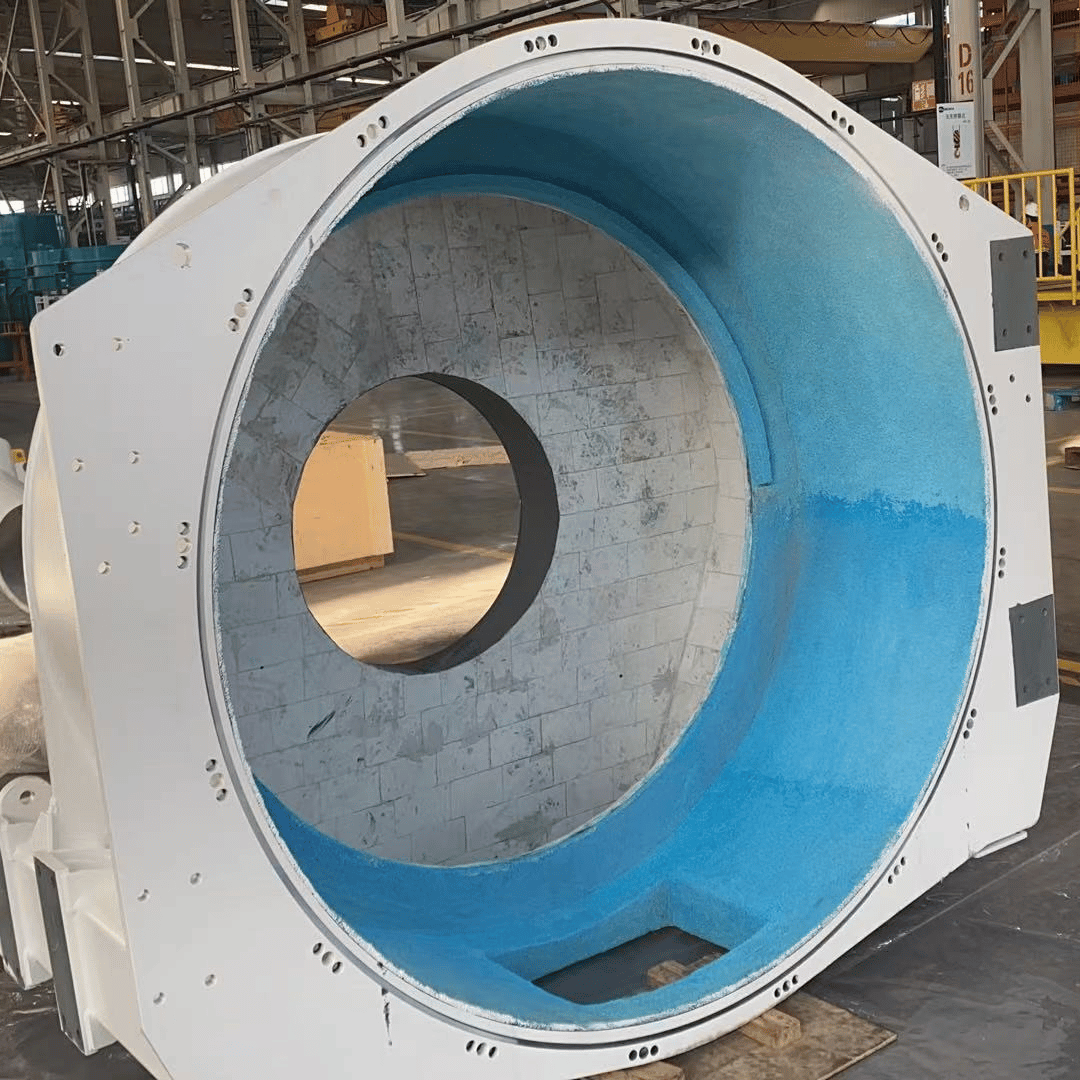

- Advanced coatings to protect critical components from abrasive media

- Optimised centrifuge basket designs for efficient fluid flow and solid separation

- Durable bowl liners, scrolls, feed distributors, and baskets

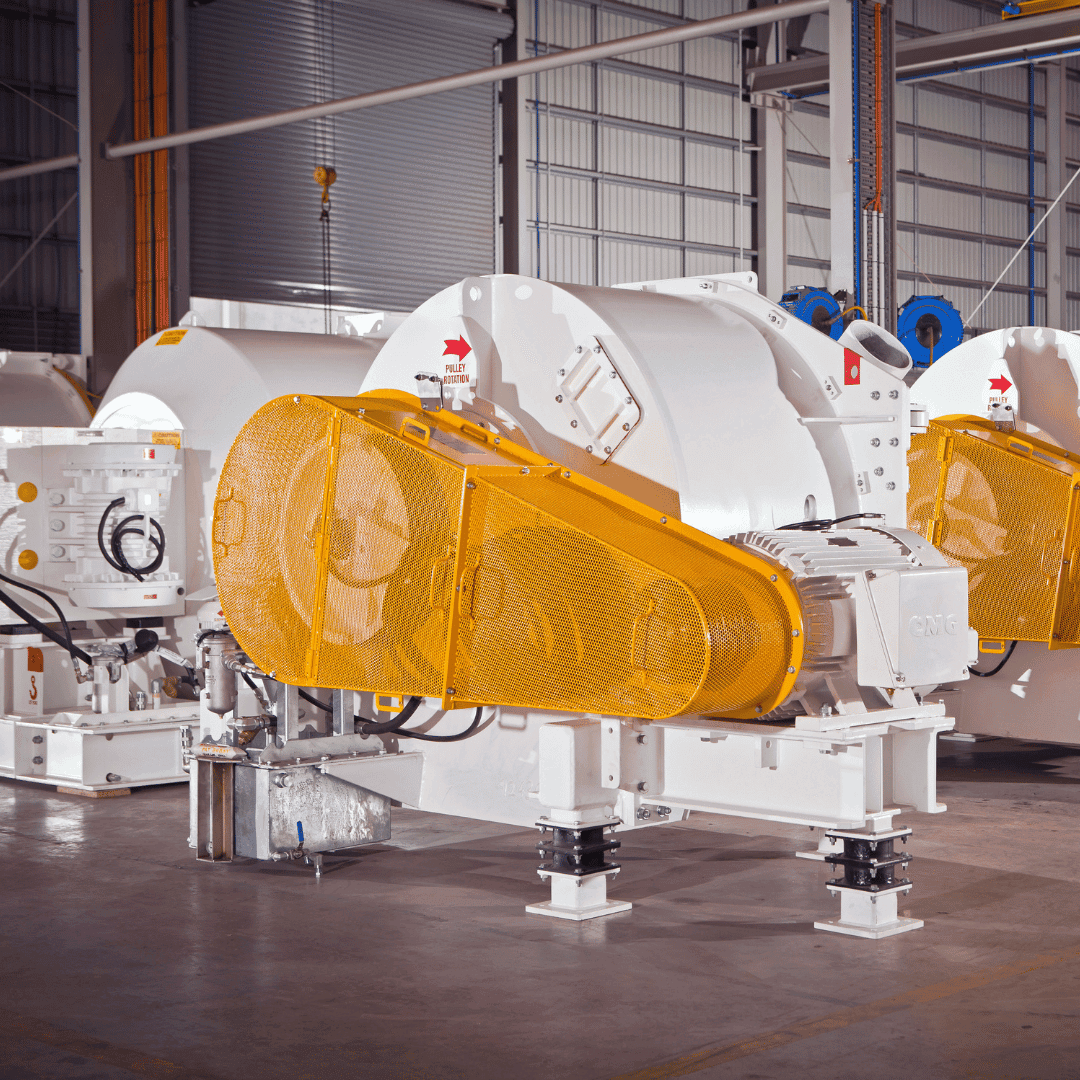

- Precision-engineered for minimal friction and smooth rotation

- Compatible with multiple centrifuge types (screenbowl, decanter, basket)

- Designed for high-capacity operations under demanding conditions

- Reinforced construction for extended component lifespan

- Engineered for optimal separation performance and consistent dewatering

- Low-maintenance modular design reducing downtime and service effort