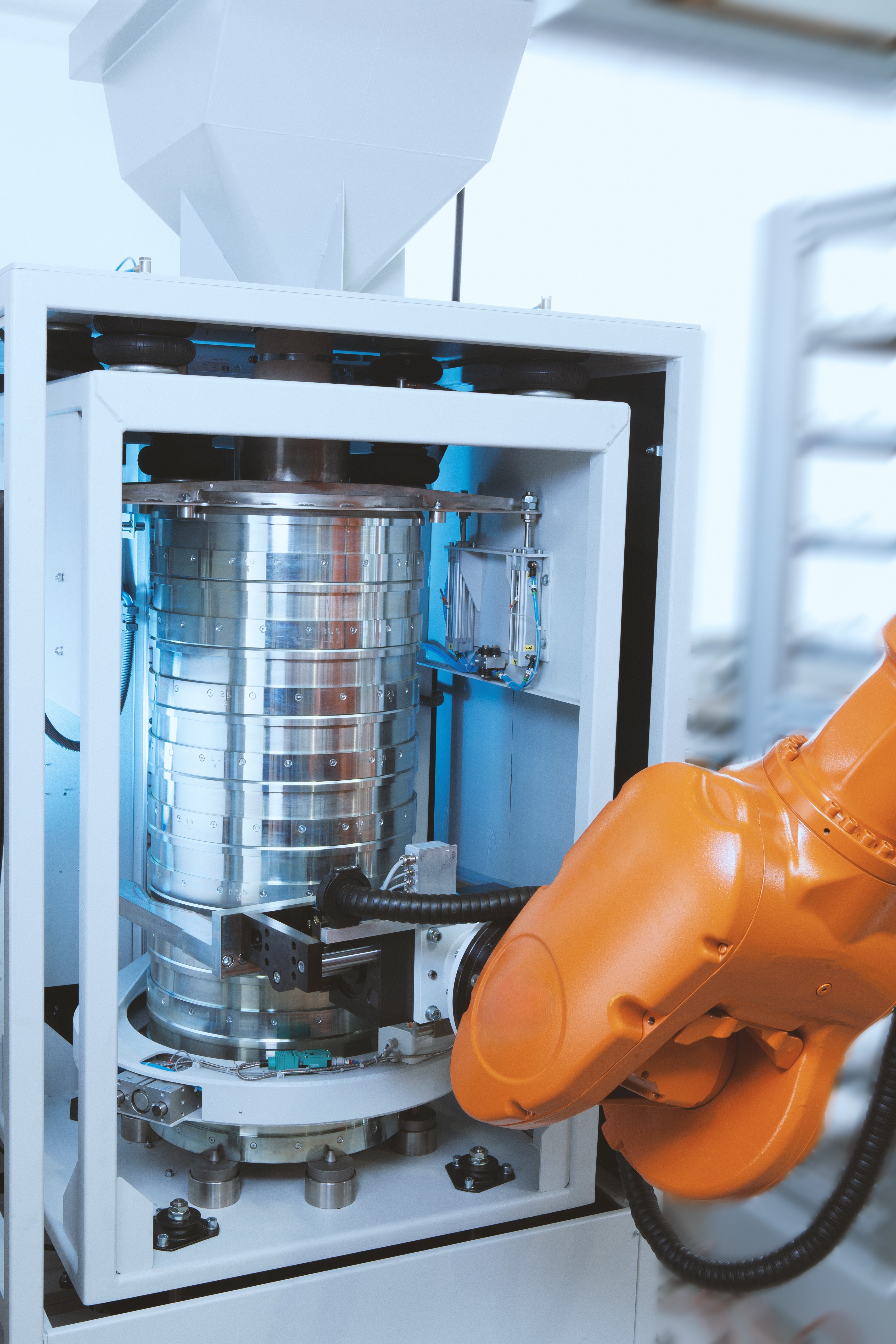

HP-SST Fully Automated Sieve Shaker

Fully automatic screening of lump ores and other samples - for maximum accuracy and process reliability.

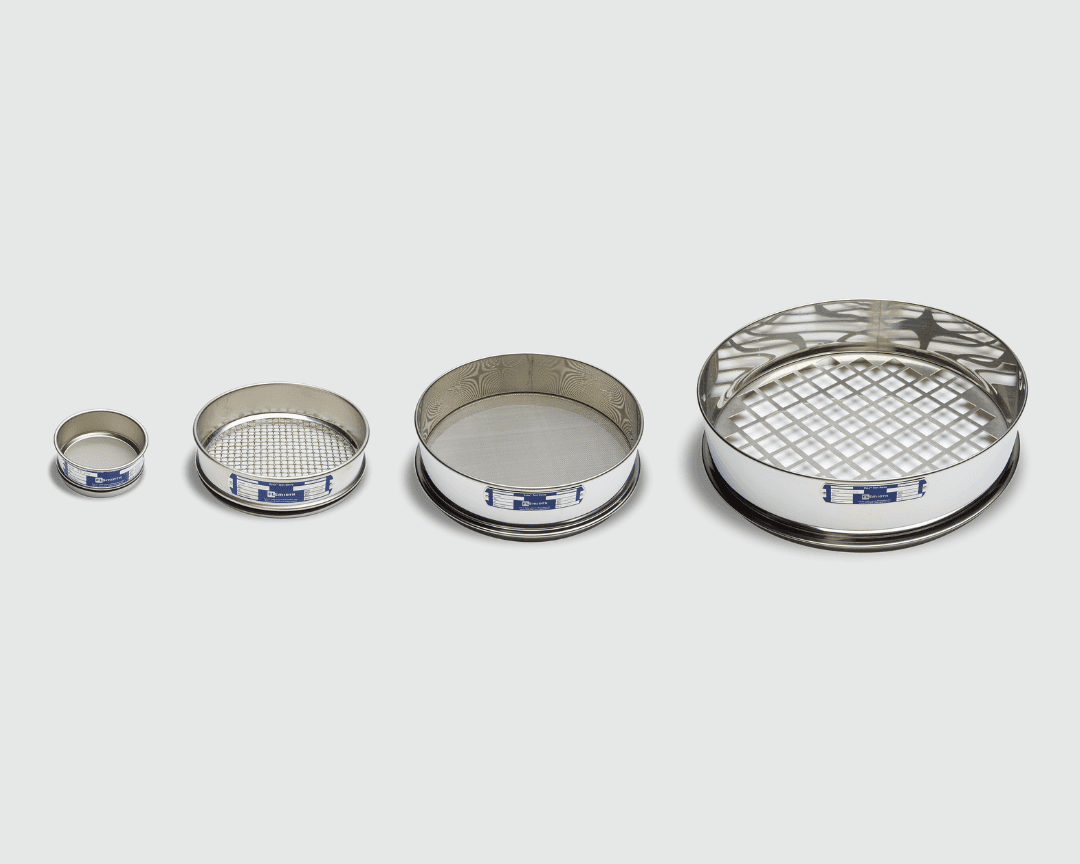

Developed for ISO-compliant sieving in the mining industry, the HP-SST enables the effective determination of the particle size distribution of a sample by means of screen sieving. The machine can accommodate up to 8 full-height 450mm sieves of different mesh sizes. The machine was developed for integration in robot laboratories and ensures, for example, the determination of the particle size fractions of iron ore samples in accordance with ISO 4701.

The HP-SST is designed for optimized processes. The sample is fed into the HP-SST by the robot via a hopper and the sieving process is started by means of oscillation movements. At this point, the screens are firmly and securely clamped by the clamping unit. Once the sieving process is complete, the clamping unit is automatically moved so that the screens can be removed by the robot.

The screens are automatically emptied and cleaned. The discarded oversize particle fractions are weighed to determine the respective particle size fraction. The emptied sieves are then placed on a separate scale to determine if there are any plugged particles in the sieve. If a certain limit value for the acceptable percentage of plugged particles is exceeded, the sieve can be discharged into a magazine for manual cleaning by the operator. Otherwise, the emptied and cleaned screens are temporarily stored and then reloaded into the automated sieve shaker by the robot in reverse order. The HP-SST is then ready for the next sample.