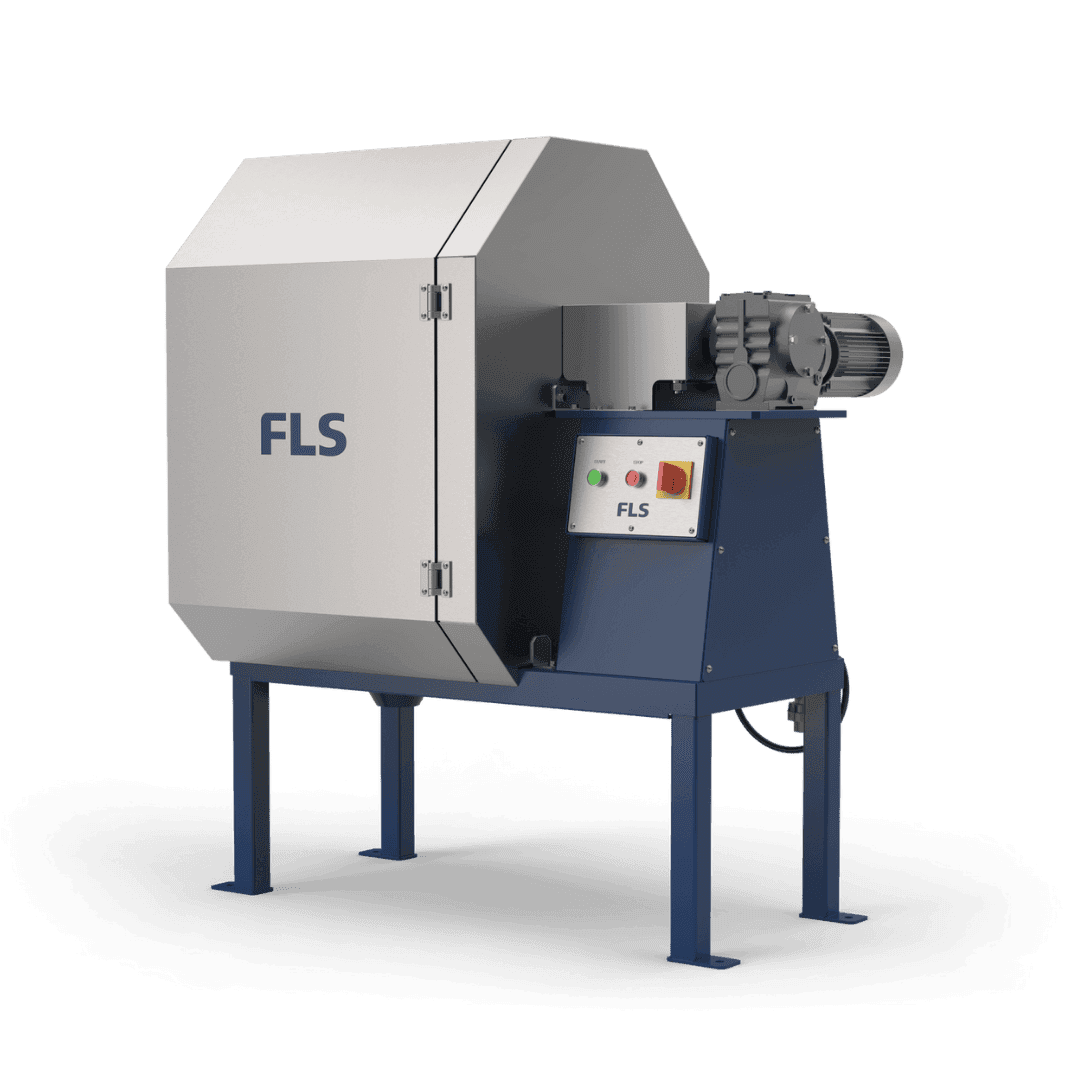

Essa® Certified Plant and Laboratory Pressure Filters

Essa® Pressure Filters have been completely redesigned and built to comply with pressure vessel standards around the world. The new design gives you more productive filtration than ever before. Use them to separate solutions on mine sites, in gold rooms, assay laboratories and other metallurgical test facilities.

When batch pressure filters were put under the spotlight in 2015 by the Government of Western Australia as posing a risk to mine safety, we were quick to respond. Our redesigned pressure filters achieve worldwide compliance, satisfying Pressure Equipment Directive 2014/68/EU, ASME VIII and AS 1210. We’re confident they will be the safest and easiest pressure filters you’ve ever used.

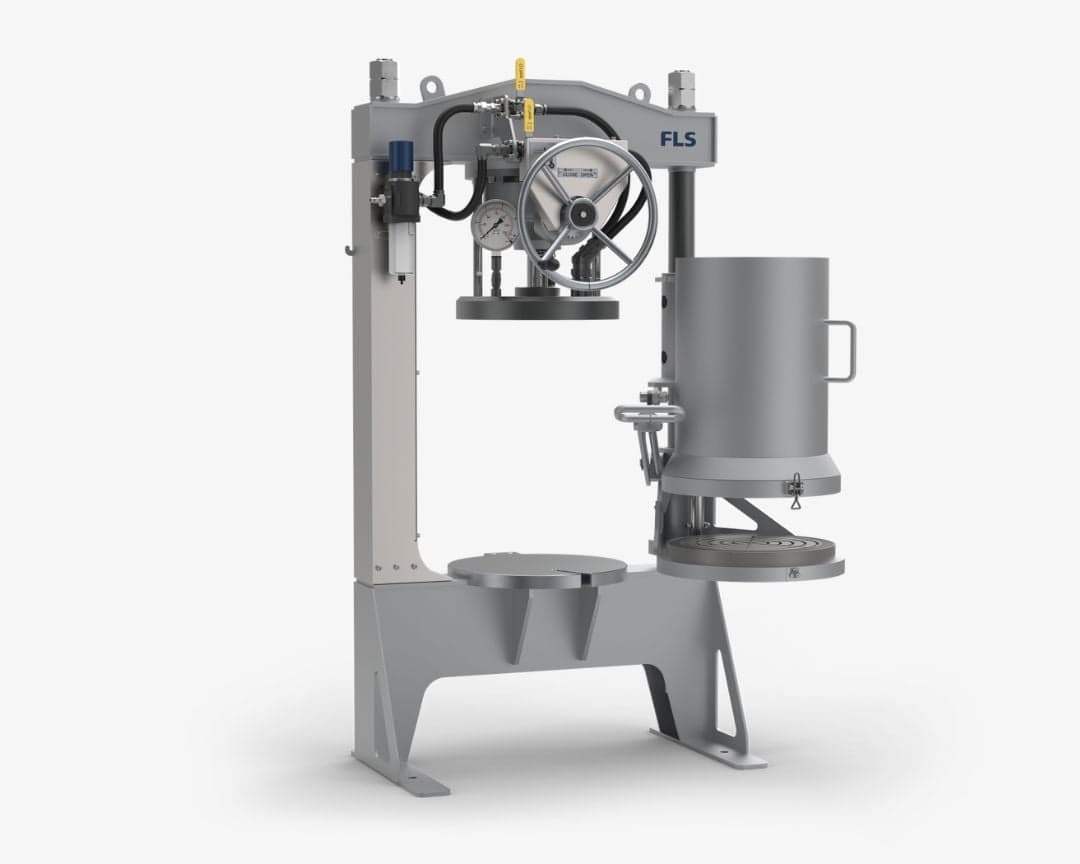

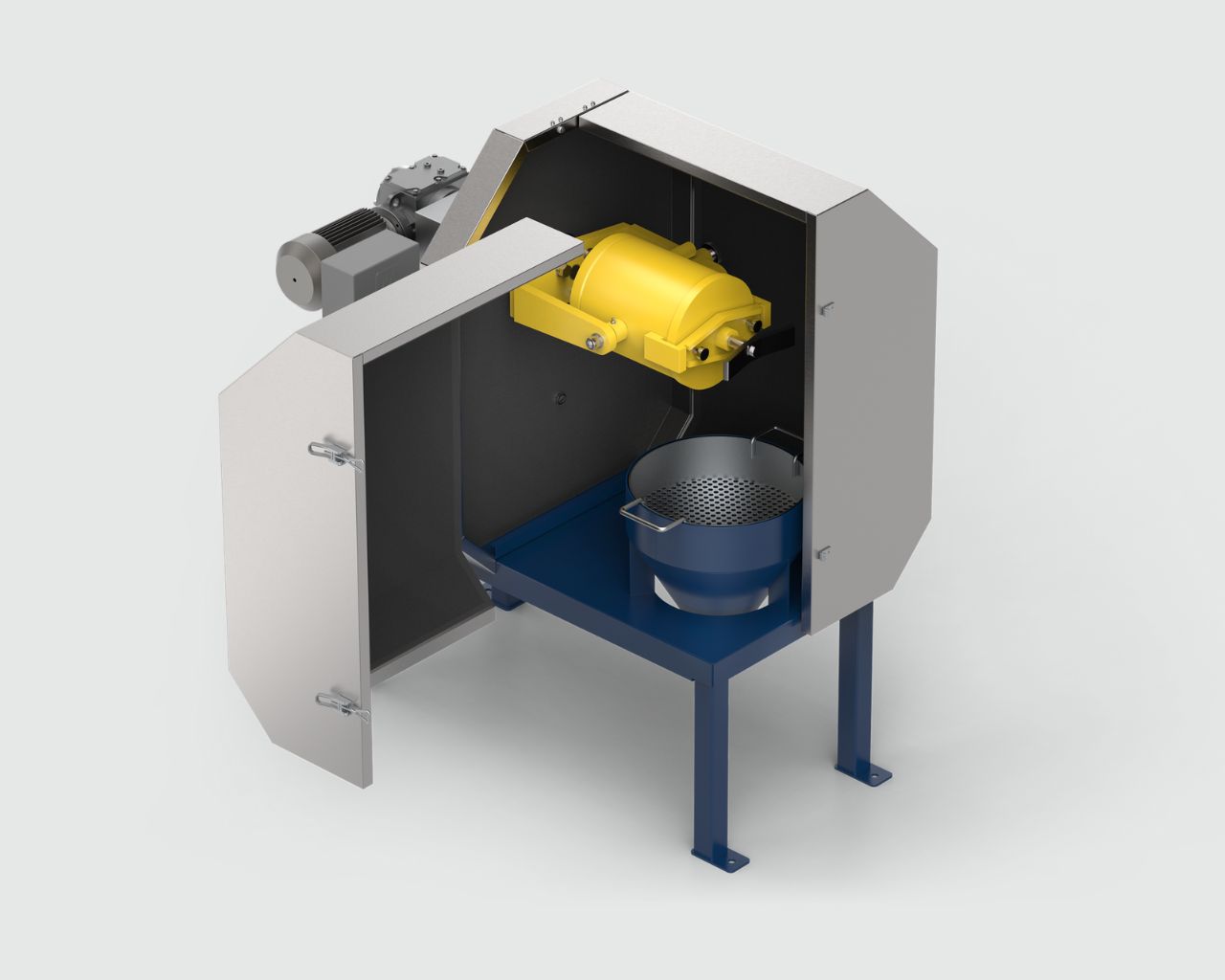

Safety

Locking mechanisms on the lid clamping wheel prevent the wheel being turned or the lid opened while there is still pressure in the barrel. A shield around the base of the barrel protects you in case any liquid sprays out of the barrel while under pressure.

Ergonomics and productivity

The new user-friendly design gives you vastly improved productivity. Easy-to-use clamping and a rotating base enable users to load and unload faster than ever before. The barrel easily lifts off the filter cake via a simple lever arrangement, reducing the risk of contamination or sample loss.

Longevity

Our Pressure Filters are built almost exclusively with stainless steel materials and fittings so you can use and rely on them long term, even in corrosive or damp conditions.

The units can operate at pressures up to 1380 kPa (200 psi), speeding up the filtering of less compactible materials.