Unlock more sustainable crushing

As mining companies strive to reduce energy use, focus often falls on the comminution circuit, which is estimated to consume nearly 40% of a mine’s total energy use. Milling and grinding accounts for much of this, but is only part of the comminution circuit. At the start of the comminution circuit lies the primary crusher. The ERC eccentric roll crusher represents a transformative innovation in this space, offering improved efficiency, energy consumption, and flexibility in hard-rock crushing while delivering an optimised mill feed that enhances SAG mill efficiency.

Step forward the ERC eccentric roll crusher

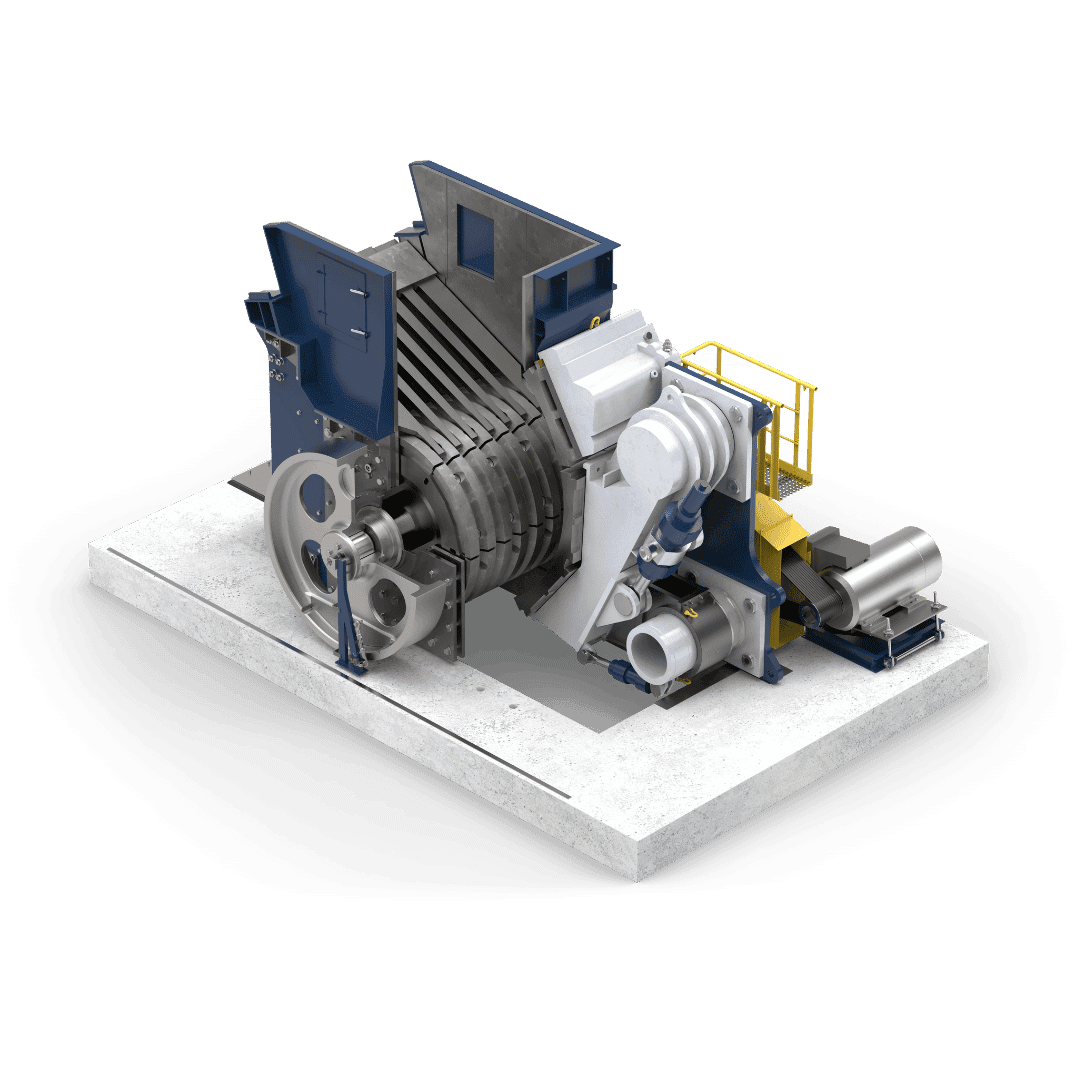

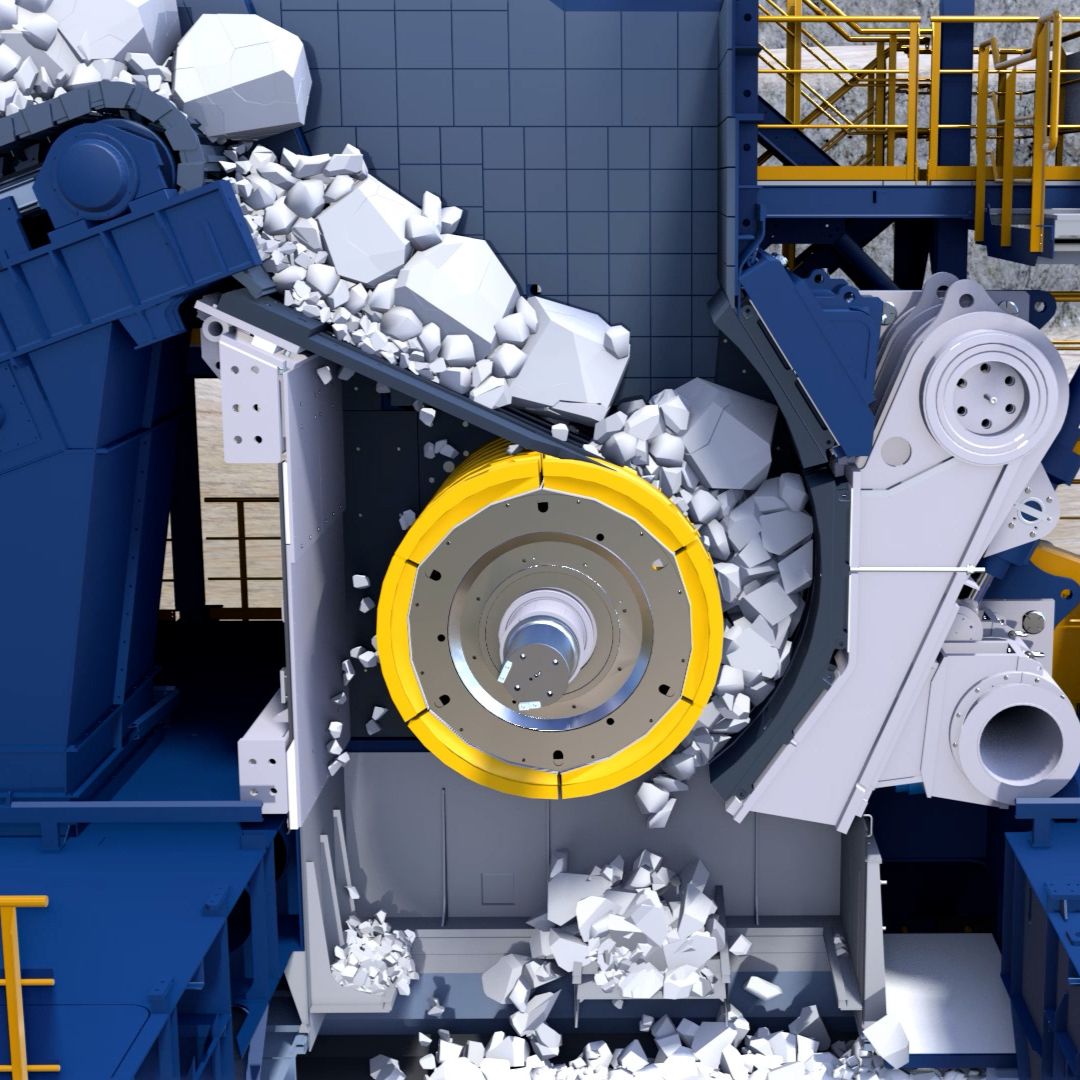

Developed as part of our MissionZero Mine initiative, the ERC eccentric roll crusher combines the functions of a crusher and a screen into one compact unit. Its integrated static grizzly screen separates fines before entering the crushing chamber. This bypass mechanism reduces the load on the crushing system, avoiding material compaction and overloading the crushing chamber; it also reduces wear, extending component operating life.

A unique kinematic design lies at the heart of the ERC eccentric roll crusher’s efficiency. An oscillating roll moves with a constant stroke, maintaining consistent crushing dynamics across the chamber. Meanwhile, high-inertia flywheels store and release crushing energy, reducing peak load demands and enabling up to 60% lower power draw than traditional jaw and gyratory crushers in similar applications.

For example, in a brownfield retrofit study, replacing a jaw crusher with an ERC eccentric roll crusher increased throughput and delivered a higher crushing ratio/smaller product, while maintaining or reducing energy consumption, even when handling harder ores. This is a game-changer for operations facing declining grades and more competent ores. The ERC protected against throughput losses, reduced primary crushing OPEX by 35%, and improved mill feed quality, supporting better downstream grinding performance.

Cutting the cost of crushing

The ERC eccentric roll crusher’s advantages extend beyond crushing energy consumption. Its compact footprint and low installation height - up to 50% less than conventional crushers - require less excavation, steel, and civil infrastructure, resulting in significantly lower CAPEX costs. In underground mines, for example, this translates into up to 20% less cave excavation and 10% lower CAPEX. In surface operations, the shorter bench height requirement also simplifies integration into in-pit crushing and conveying (IPCC) systems.

With a higher reduction rate than other crushers, the ERC eccentric roll crusher may, in specific cases, eliminate the need for a secondary crushing stage, resulting in further potential efficiency improvements and cost reductions.

A final crucial feature of the ERC eccentric roll crusher is its patented hydraulic gap setting and tramp release system, enabling automatic adjustment during operation. This ensures optimal crushing conditions throughout the liner’s life, reducing maintenance events, improving safety, and ensuring a consistent mill feed. Combined with an extended wear part lifecycle and reduced vibration thanks to its balanced design, the ERC helps miners cut maintenance costs while maximising uptime.

A flexible crushing solution

From copper and gold to platinum and overburden, the ERC eccentric roller crusher is proving its versatility across commodities. Whether increasing plant capacity, reducing energy costs, or simplifying infrastructure, it supports mining companies in achieving their productivity and sustainability goals. In short, the ERC eccentric roll crusher isn’t just another piece of equipment - it’s a smarter way to crush, and a key enabler of our MissionZero Mine flowsheets of the future.