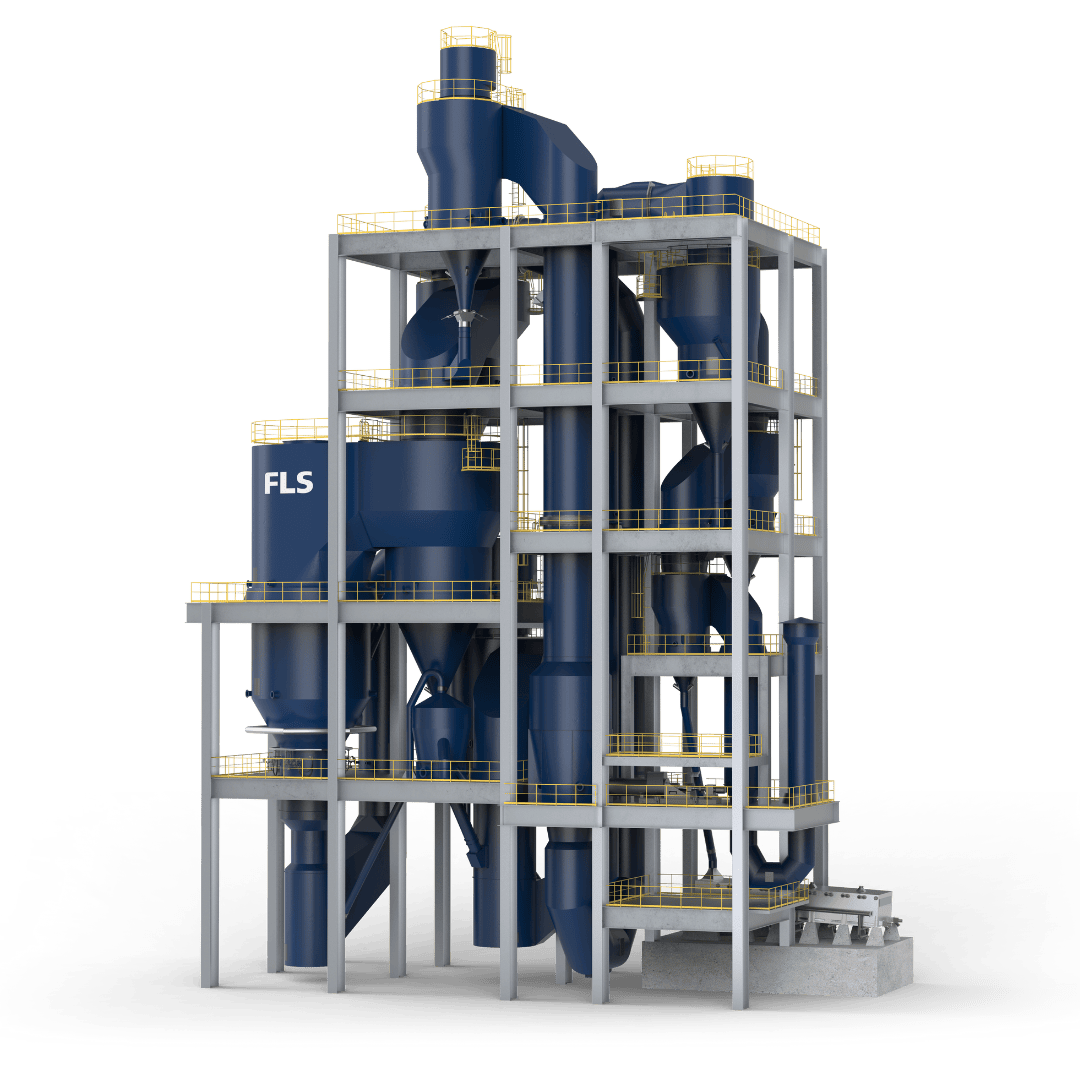

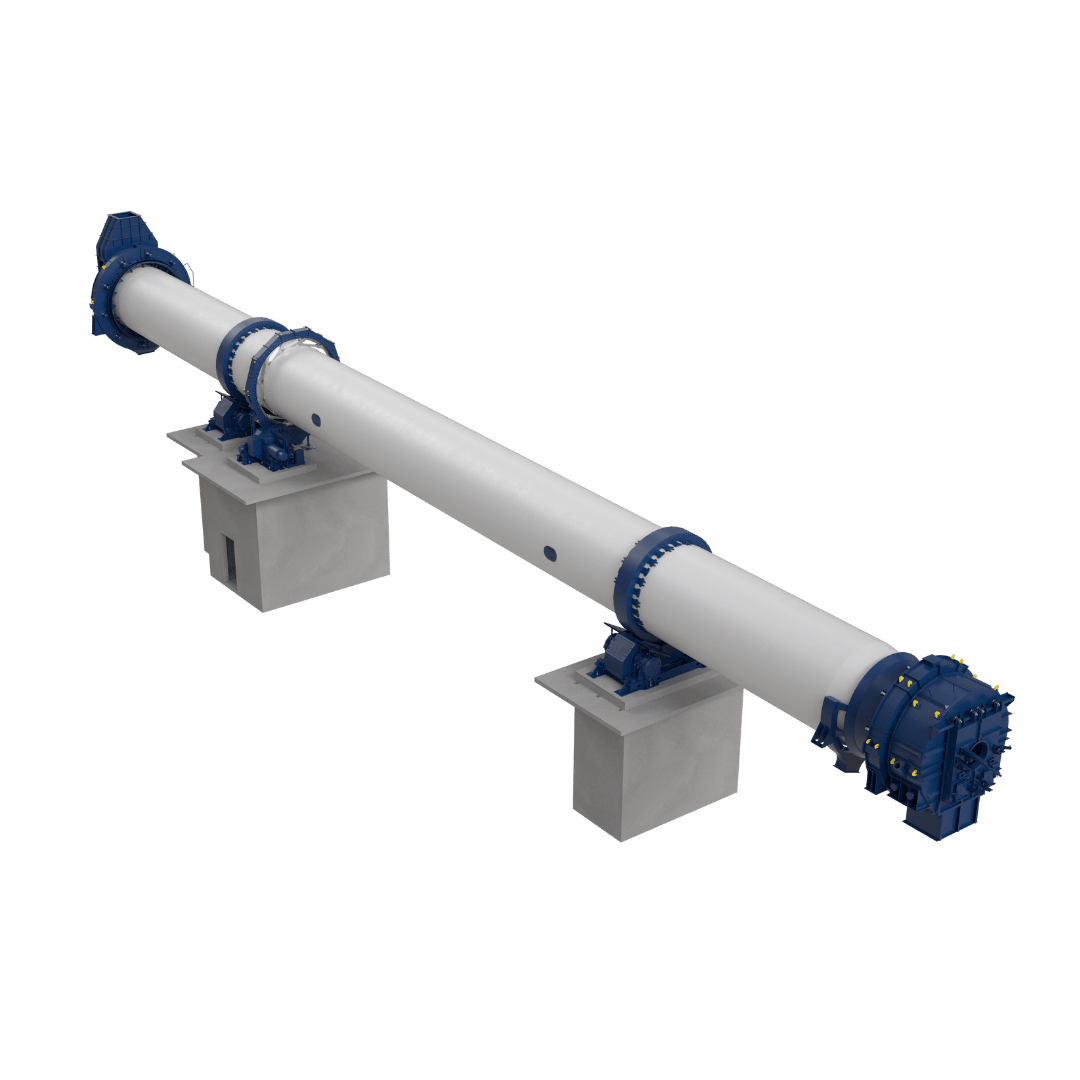

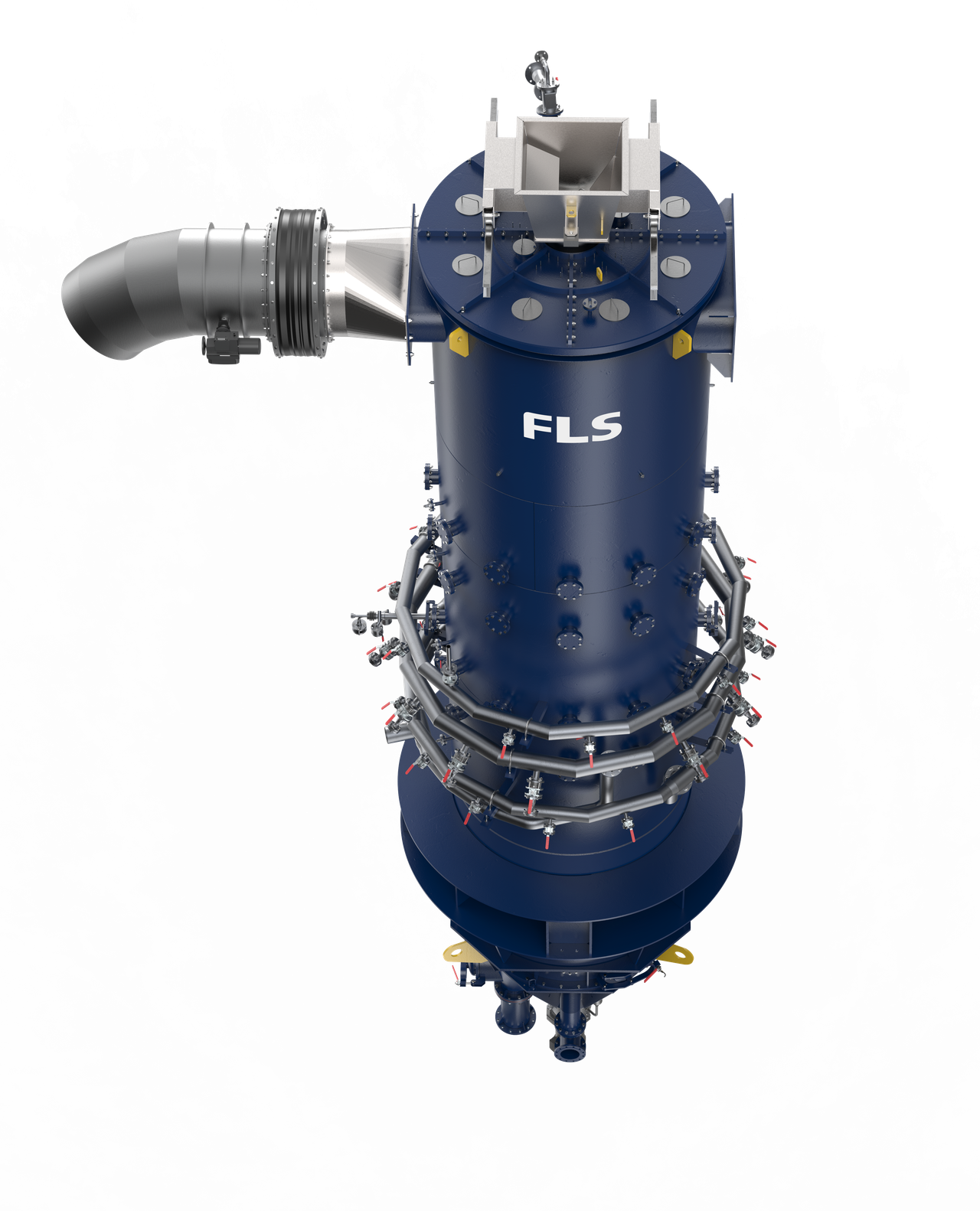

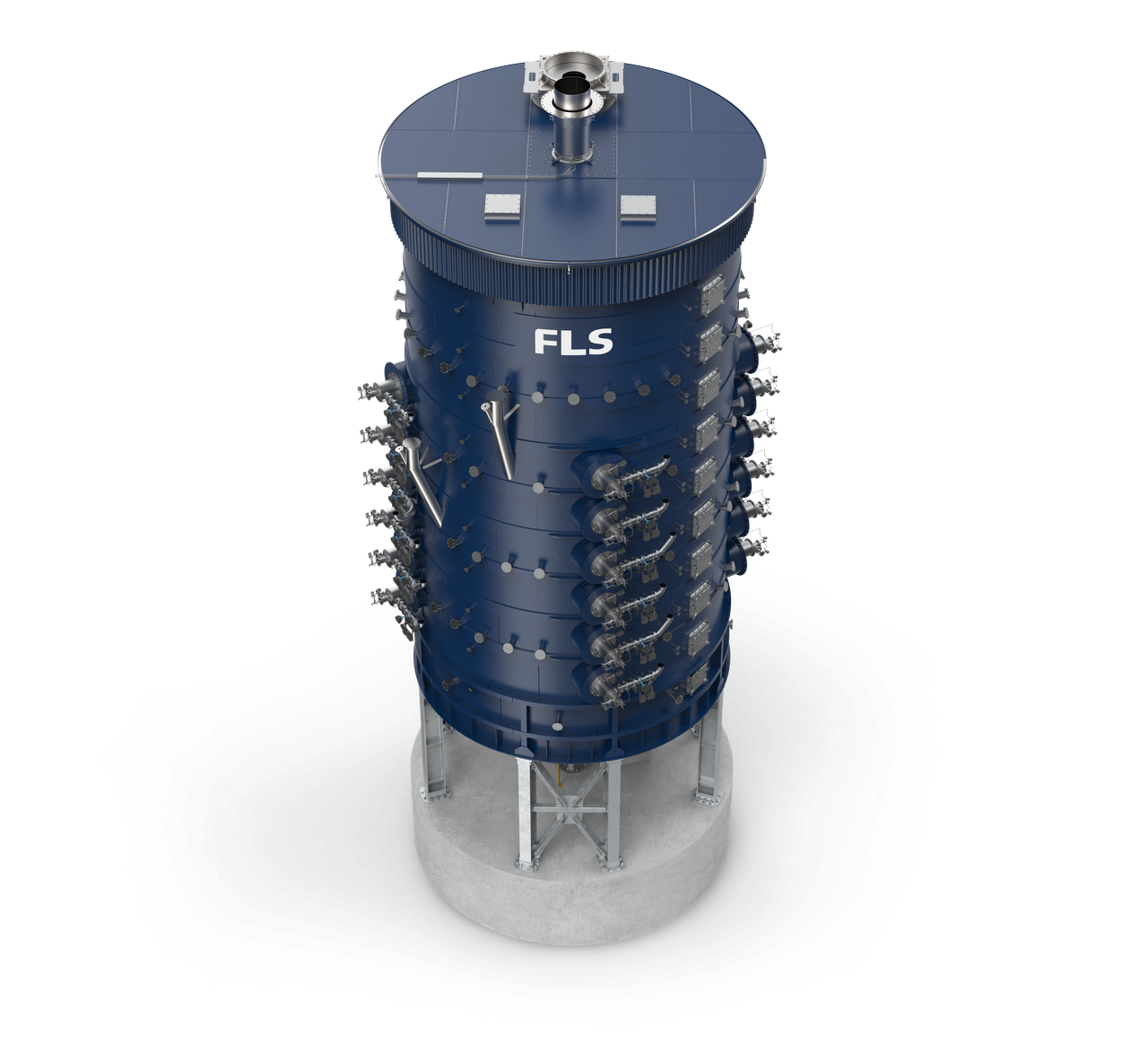

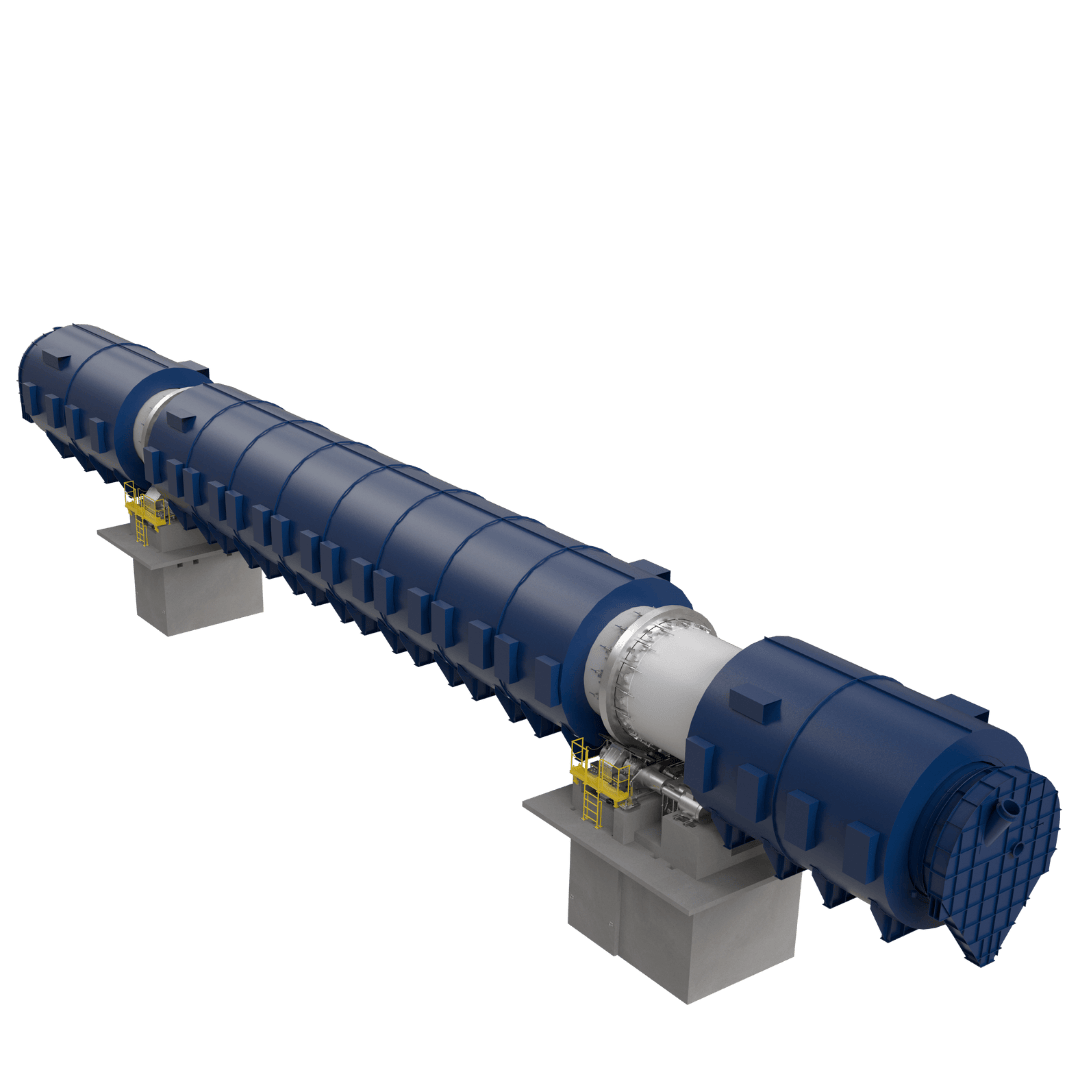

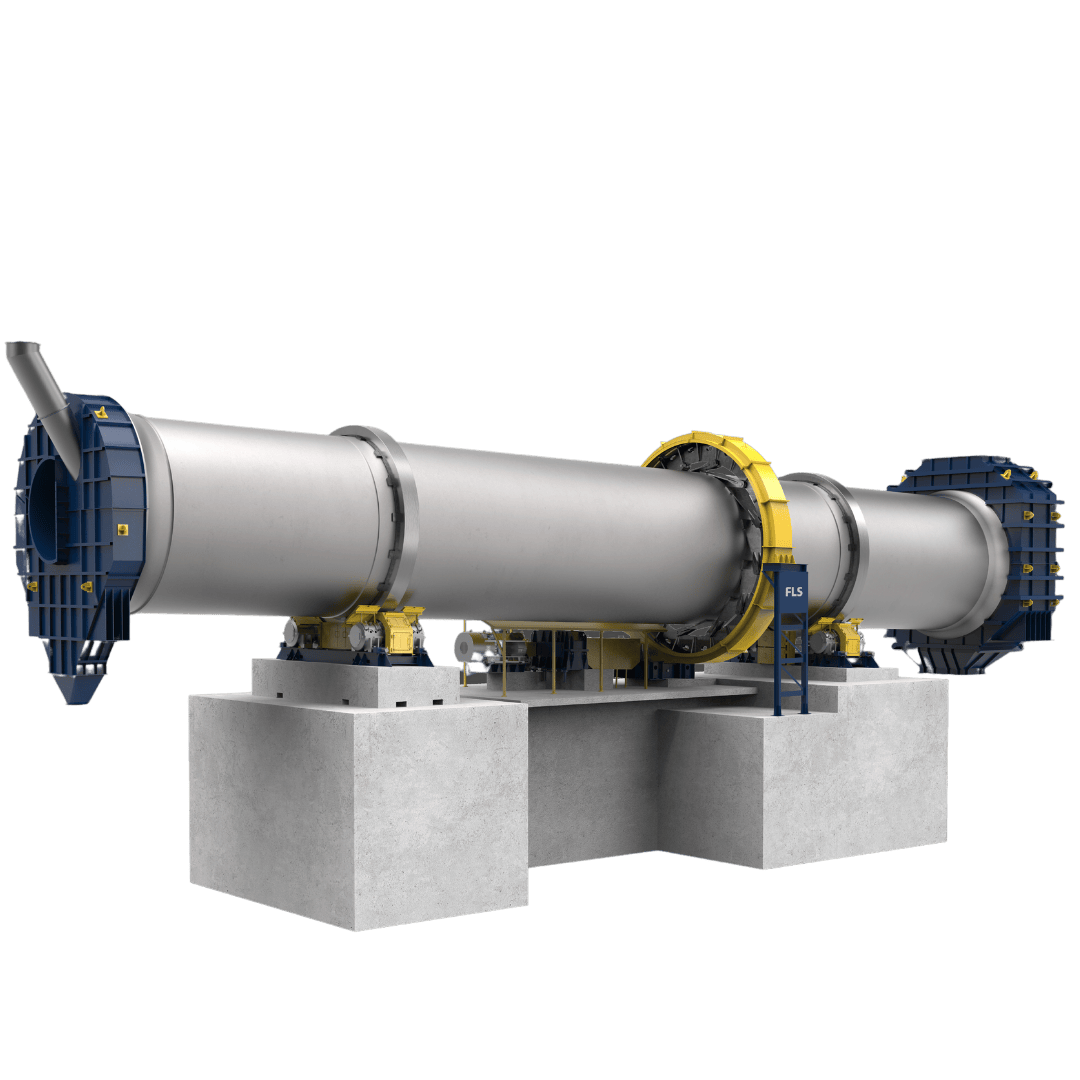

Explore our pyrometallurgy solutions

Total lifecycle support for your pyroprocessing equipment

Our total lifecycle support assists and advises you through design, installation, commissioning, troubleshooting, and optimisation of your pyro processing equipment. This includes complete in-plant consultations and plant surveys, supported by our Pyro Technology Centre of Excellence in Allentown, Pennsylvania, aftermarket spare parts, service support, refurbishment, upgrades and pilot testing services.