Date

23-26 February 2025

We are participating in SME 2025, sponsoring events and technical presentations. Visit our booth no. 1205 to see our latest solutions in crushing, milling, dewatering, tailing management, and service packages for process maintenance and enhancement.

23-26 February 2025

Colorado Convention Center, 700 14th St. Denver, CO 80202

#1205

Explore the 3-day agenda featuring expert speakers and sponsored sessions.

| Time | Presentation | Speakers |

| 3:45 PM | FLS Rail-Running Conveyors: New applications in IPCC, Steep and Long-Distance Conveying | M. Lurie; High Performance Conveyors, FLSmidth Mining, Greenwood Village, CO |

| 3:25 PM | Industrial Mineral Flotation Using Novel Coarse Particle Flotation System: CoarseAIR™ | J. Bowden, H. Patel and L. Christodoulou; Mining R&D, FLSmidth, Bethlehem, PA |

| Time | Presentation | Speakers |

| 9:45 AM | Online Analyzers: A history of Measuring Unrepresentative Sample Streams to a Future of Real-Time Metal Accounting | K. Keet and R. NOVAES; Sampling, Preparation, & Analysis, FLSmidth and Co A/S, Valby, Denmark |

| 3:25 PM | 3D Characterization of Micro-Cracks in Silicate-Rich Crushed REE Ore Particles for Fluid Transportation and Carbonation | Jaramillo¹, J. Jin¹, X. Wang¹, P. Chu² and R. Zahn³; ¹Materials Science and Engineering, The University of Utah, Salt Lake City, UT; ²University of Nevada Reno, Reno, NV and ³FLSmidth, Midvale, UT |

| 2:25 PM | REFLUX™ Flotation Cell Full-scale Trial in a Copper Concentrator Cleaning Application | Saurabh¹, B. Dabrowski³, L. Christodoulou¹, M. Czekajlo², Kwiatkowski², E. Kasinska-Pilut² and R. Pepkowski²; ¹Global Product Line Management, FLSmidth Inc., Midvale, UT; ²KGHM, Polkowice, Poland and ³Mineral Testing $ Research Center, R&D, FLSmidth Inc., Midvale, UT |

| 3:45 PM | Investigating the Flotation Performance of CoarseAIR™: Sulfide Mineral Applications | H. Patel, J. Bowden and L. Christodoulou; FLSmidth, Midvale, UT |

| Time | Presentation | Speakers |

| 9:45 AM | Lessons Learned from a Year of Continued Data Analysis on a High Performance Belt Conveyor Using Conveyor Digital Twinning | Ormsbee; FLSmidth, Denver, CO |

| 11:05 AM | Moly Flotation: A Case Study – NaHS or Na2S? | S. Merrill and N. Kadappan; FLSmidth Inc, Riverton, UT |

| 10:25 AM | Pneumatic Pressure as Primary Dewater Force in Pressure Filtration | C. Lutheran; Mining - Filtration, FLSmidth, Midvale, UT |

| 11:25 AM | Utilizing Cyclowash™ Technology to Reduce Fines Reporting to Hydrocyclone Underflow | Wright; FLSmidth, Brisbane, QLD, Australia |

| 3:05 PM | Computational Evaluation of Feedwell Design & Performance in Gravity Thickener | Y. Lu¹, T. Sok¹, F. schoenbrunn², J. Scott² and C. Gilbert²; ¹Ming R&D, FLSmidth, Midvake, UT and ²Thickener Products, Flsdmith, Midvake, UT |

| 2:25 PM | Performance Comparison of the Standard WEMCO and WEMCO II at 80m3 and 250m3 Industrial Scales | I. Coltrin¹, B. Forbes², T. Sok² and D. Lelinski¹; ¹Product Line Managment, FLSmidth and Co A/S, Valby, Denmark and ²R&D, FLSmidth, Midvale, UT |

| 3:25 PM | A Case of Bad Gas: The Effect of O2 in Cu/Mo Separation | S. Merrill, P. Thompson, I. Coltrin and D. Lelinski; FLSmidth Inc, Riverton, UT |

| 4:05 PM | Rethinking Froth Pump Sizing: Field Trials with Recessed Impeller Centrifugal Slurry Pumps | L. Haines; FLS, Tucson, AZ |

The conference will also feature the official launch of our new coarseAIR™ Flotation Cells. These flotation cells significantly improve mineral recovery and allow for coarser grinding in your circuit. Increase plant throughput, overall recovery, and support your ESG goals of energy, water and tailings management with this REFLUX™ technology.

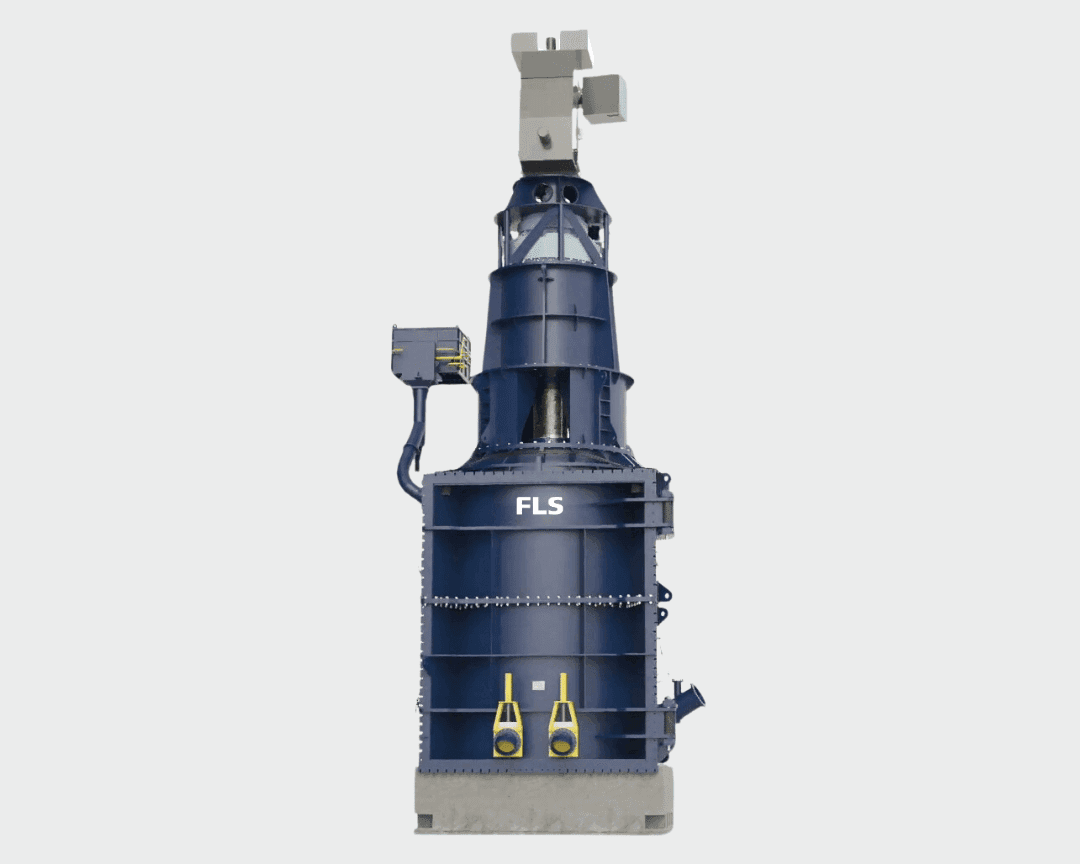

FLS Tower Mills deliver unmatched energy efficiency and precise particle size control, enabling operations to sustainably maximise productivity while reducing operational costs.

The REFLUX™ Flotation Cell (RFC™) radically alters perceptions of froth flotation performance. It operates at extreme levels of gas and feed flux, and fluidisation wash water to deliver up to tenfold higher throughput, with enhanced grade and recovery, all with a smaller plant footprint.

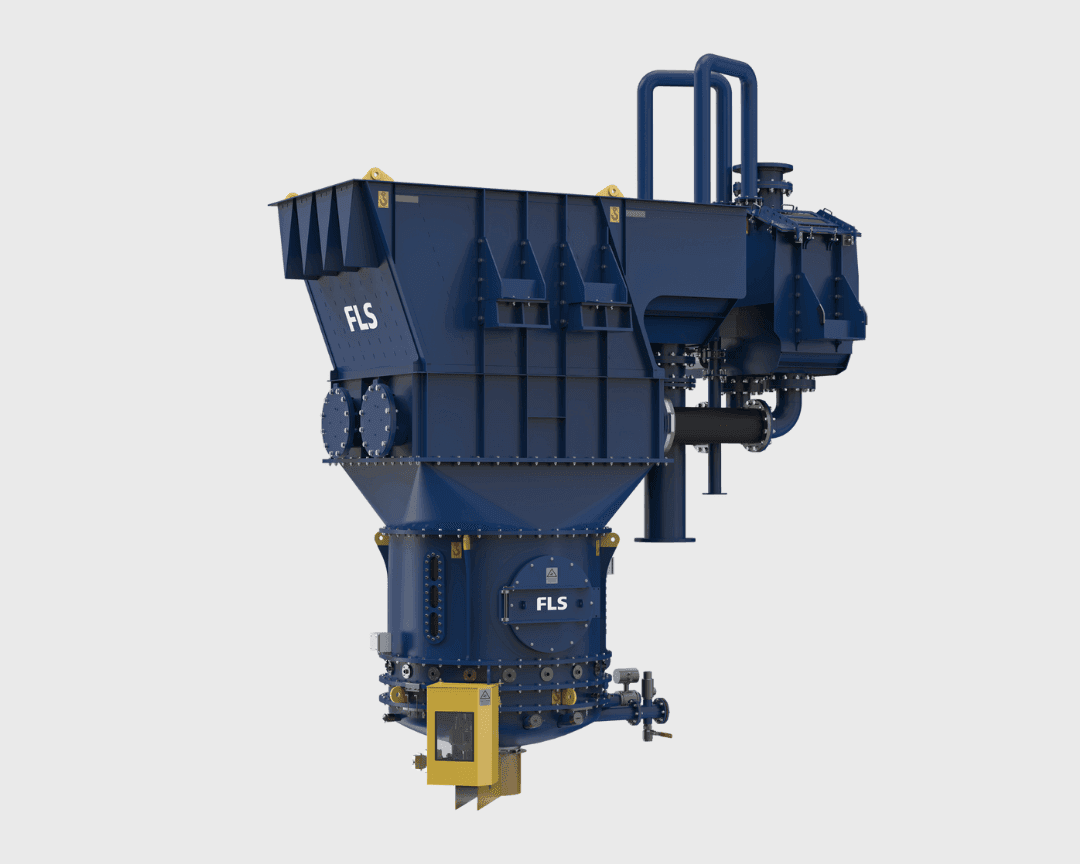

As the need for filtered tailings management increases, so does the demand for high-efficiency, large-capacity, dewatering equipment. With the AFP2500 Automatic Filter Press, you can expect an average of 93% availability and up to 95% recovery of process water.

Learn more about the efficient and reliable WEMCO® II flotation cell is improving on the already excellent WEMCO. Providing excellent aeration, mechanical simplicity, and CAPEX efficiency, WEMCO II self-aspirating flotation cells deliver highly productive and economic flotation performance.

KREBS® horizontal slurry pumps are designed to reduce power consumption by up to 30%. They offer multiple wear material options and optimised hydraulic performance to extend liner and impeller wear life, resulting in longer pump uptime.

Since 1952, KREBS® has manufactured industrial hydrocyclones, recognised for their technical quality. The versatile gMAX hydrocyclones are utilised in various industries, including mineral processing, oil sands, power, chemicals, and water treatment.

With over 100 years of successful installations, FLS has established itself as an industry leader. By delivering robust and high performing equipment, crusher liners and the tooling to maximise safety, trust in a partnership with FLS to deliver crushing solutions based on your needs and goals.

Maximizing throughput and ensuring reliable milling are key to boosting your bottom line. Our range of mills, equipped with ARMOUR™ mill liners, offer the flexibility to suit your specific needs while delivering the durability and efficiency you expect from a global leader in grinding.

Screens play a critical role to ensure smooth material transition with efficient classification. Our comprehensive selection of high-performance screening equipment, paired with industry-leading screening media, provides precision-engineered solutions tailored to your unique operational challenges – helping to reduce costs and boost productivity.

Digital transformation offers improved accuracy, higher productivity, and reduced downtime. Our global network of experts harnesses the latest digital tools and a complete suite of services to monitor asset health, optimize performance, and drive greater efficiency while minimizing downtime.

Whether you select onsite, online, or a hybrid learning approach, our mining education services are tailored to deliver a strong return on investment by boosting competence, refining decision-making, and enhancing your understanding of best practices in crushing, milling operations, and maintenance.