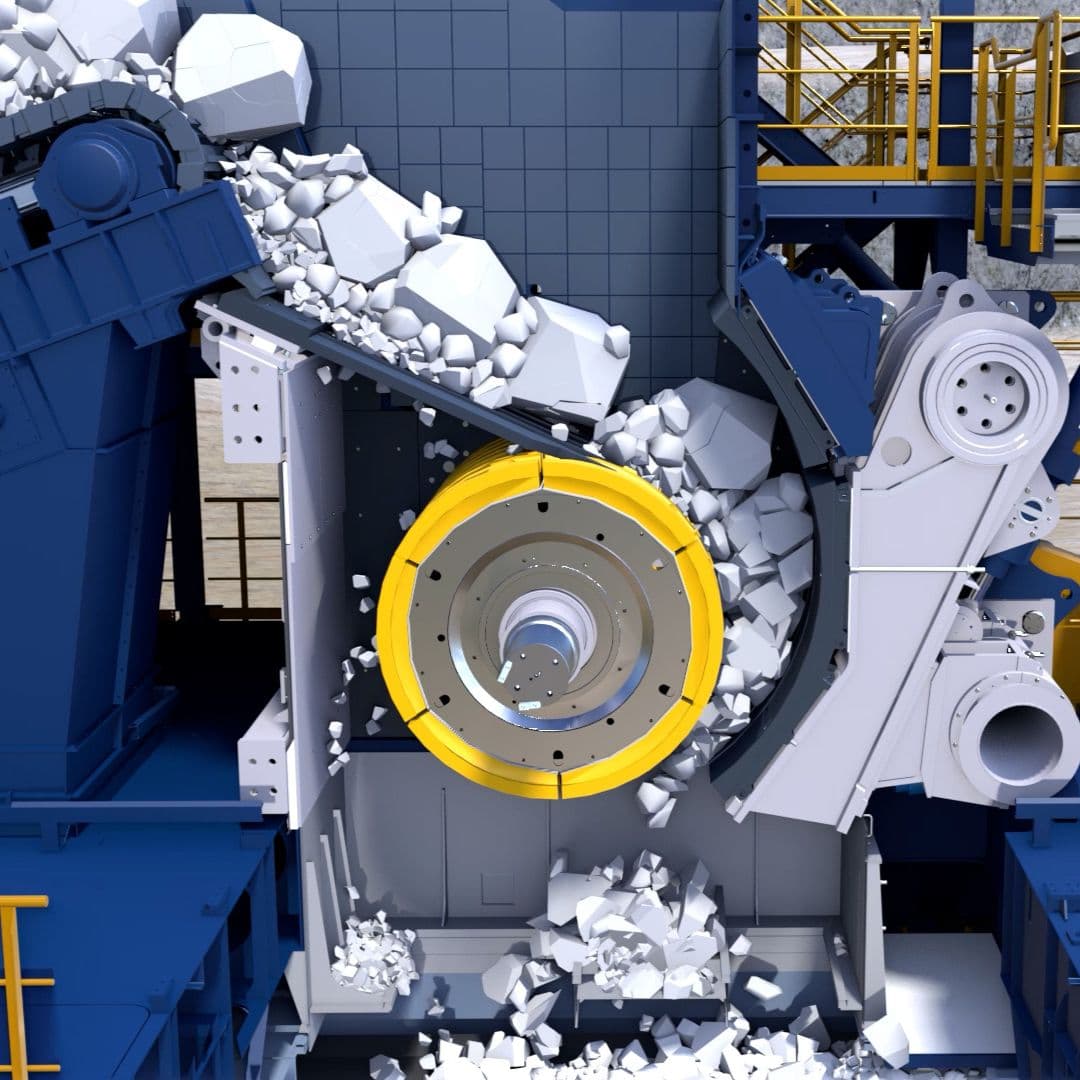

Our Eccentric Roll Crusher (ERC®) is a game-changer for primary crushing of hard rock and ore in underground and surface operations. Compact and robust, our ERC® features an integrated screen, which provides significantly higher efficiency and greater capacity than conventional primary crushers.

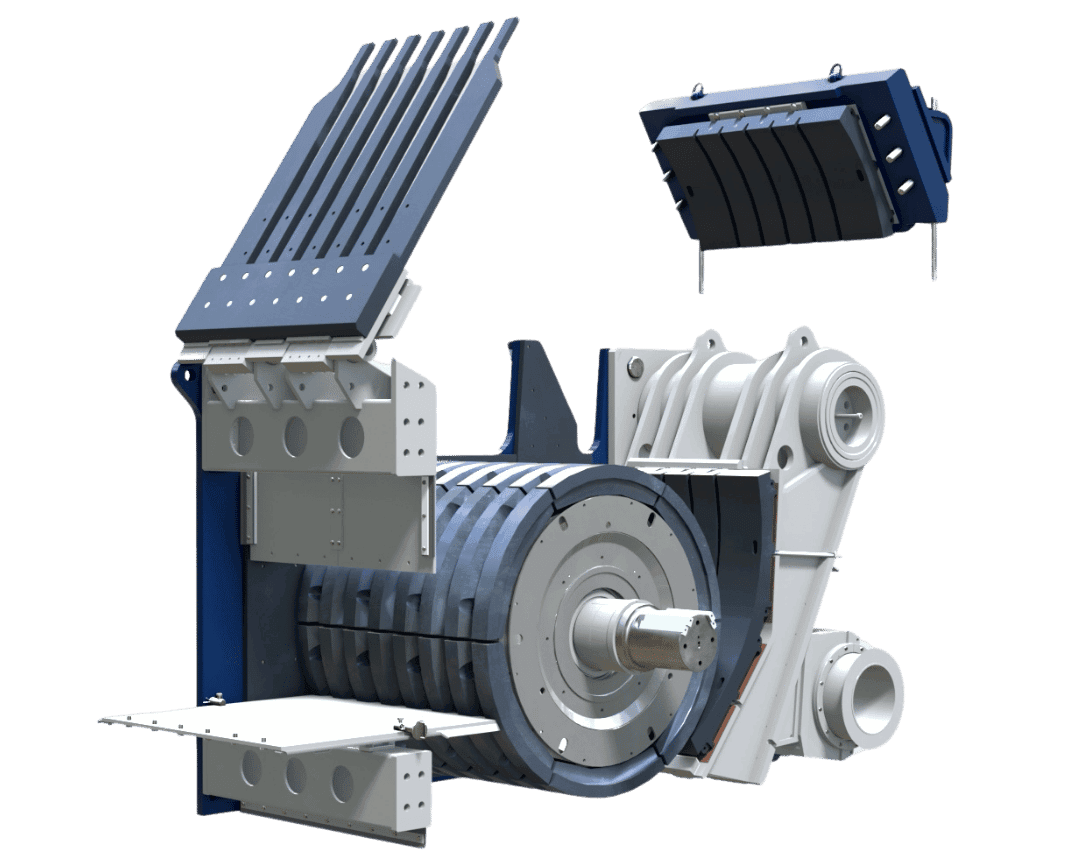

Two machines in one – The ERC combines a crusher and a screen in a compact design that simplifies transportation, installation and maintenance. The integrated screen increases the efficiency of the machine, as fine material is bypassed directly and not passed through the crushing chamber. This reduces energy consumption and the risk of material compacting and overloading the crushing chamber

Highly energy efficient crushing – The ERC is designed for outstanding comminution intensity, high throughput and the most efficient use of crushing energy, thanks to the particularly effective kinematic of the oscillating roll, with constant stroke across the entire crusher cavity. The high moments of inertia of the roll and flywheels contribute to accumulated crushing energy and effectively compensate for the load peaks that occur during comminution.