Protecting against sliding erosion

WEAR MAX is proven to reduce abrasion wear problems commonly occurring in bulk handling and processing equipment such as pipes, chutes, silos, tanks, and casings. It adheres effectively to most clean and dry surfaces including metal, ceramic, rubber and concrete. WEAR MAX reaches maximum hardness after curing for just 24 hours, based on an ambient temperature of 23°C (73°F), so you can get back to work with little downtime.

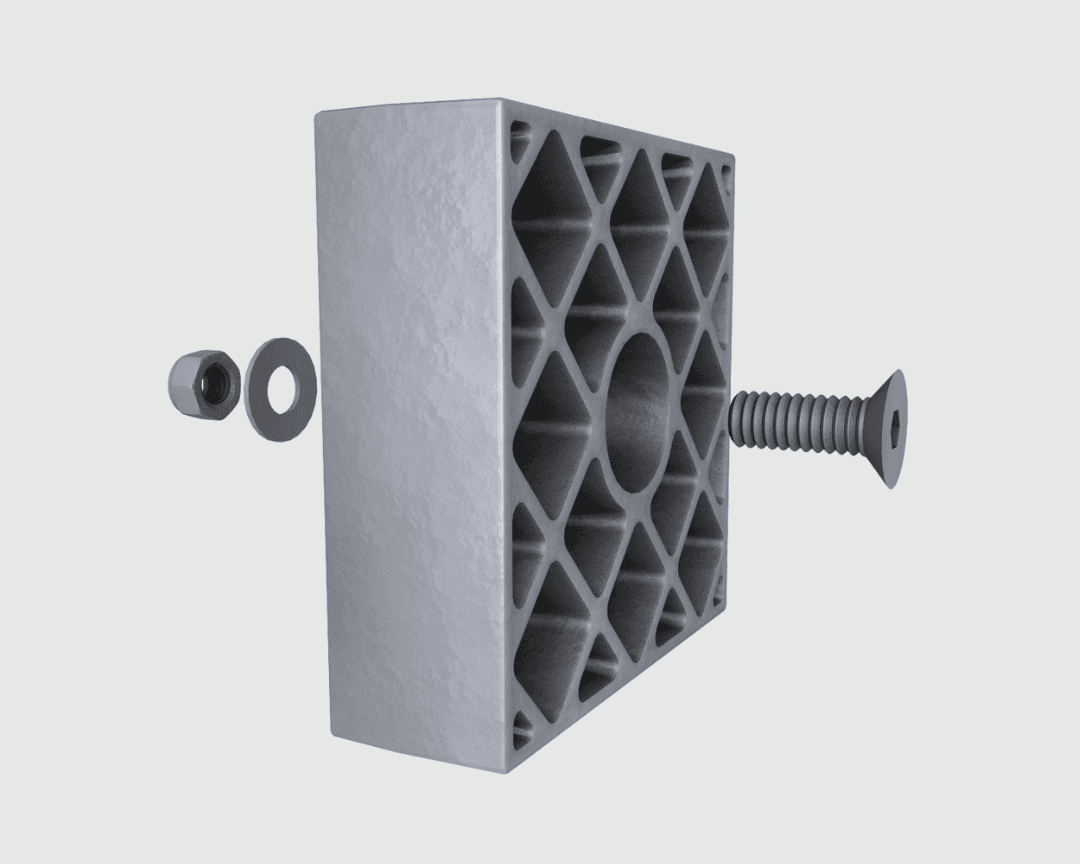

Powerful impact resistance

FerroCer are our composite wear panels, taking the advantages of malleable steel and combining them with the wear resistance of ceramic liners. FerroCer can save you money in all your high impact applications, such as discharge chutes, crushers and hoppers. From the moment FerroCer wear panels are installed, you can reduce maintenance shut-downs, operational downtime and operating costs. This combined with easy installation and affordable pricing means that FerroCer wear panels deliver the lowest total cost of ownership (TCO) on the market.

Advanced wear solutions for all applications

From pipes to centrifuges, buckets to silos, every surface that is exposed to wear has a solution within the FLS portfolio. For example, our alumina and silicon carbide ceramic lined piping systems extend the life of pipes, valves, nozzles, and more, while our impact wear panels help protect chutes from the impact of medium-sized rocks. Whatever your wear challenge, talk to us. We can help you find the optimal solution for your needs.