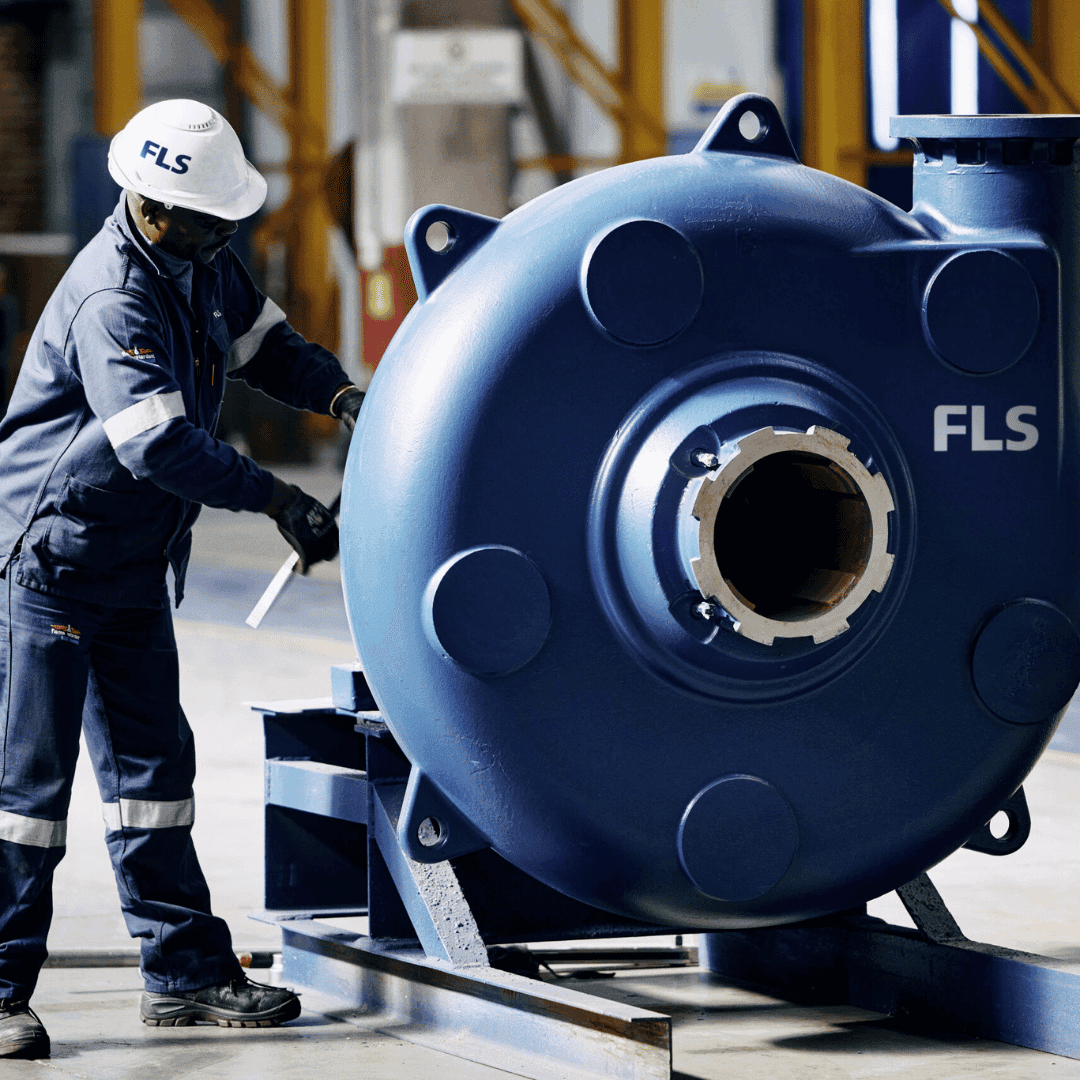

Repair and refurbishment

At our service centres in Chloorkop and Stormill, South Africa, we have the facilities for servicing, retrofitting and refurbishing a wide range of FLS products, including pumps, valves and cyclones, HPGR, gyratory crushers and gearboxes. Our rebuilds and exchange programmes provide a lower cost way to keep your machines running, giving you the high-quality components you need without the long lead time of new parts.

Spare parts

We keep a good stock of regularly need wear and spare parts and we’re also happy to support you with inventory management to avoid shortages.

Technical services

Our expert teams provide advice and guidance, troubleshooting, installation and commissioning, and a range of other services. You can think of us as your technical partner on the ground, strategically located to be close to the region’s mining operations.

Technical training

Our Training Academy nurtures highly skilled artisans who contribute to both the service centre and the market. A three-year comprehensive apprenticeship programme allows the company to develop the sought-after skills the market needs and provides a constant pool of talent within the company for succession planning and growth opportunities.

In addition, we can develop bespoke training programmes that meet your needs, to ensure you’re getting the maximum performance from your equipment through operational and maintenance best practice.