Better support, reduced lead times

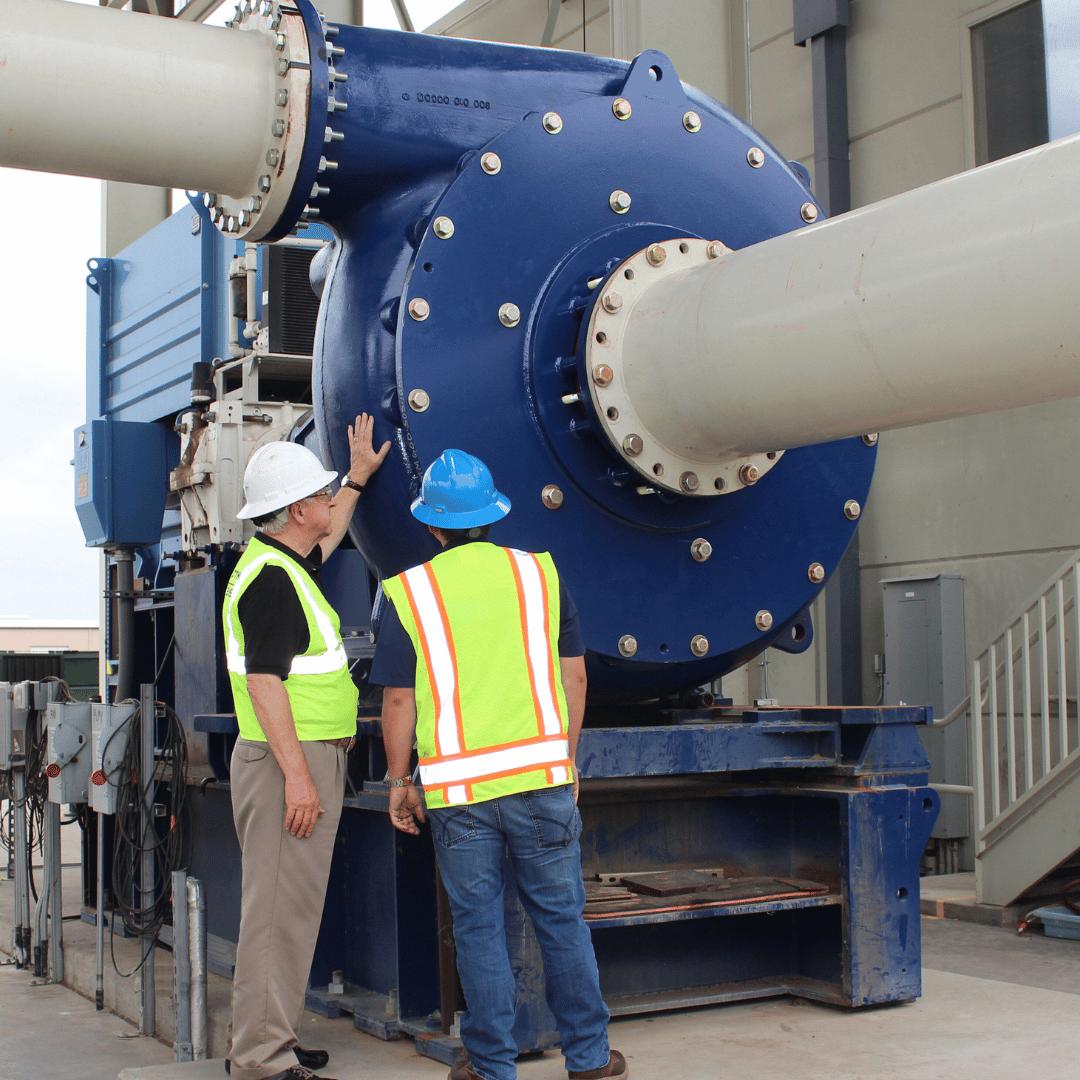

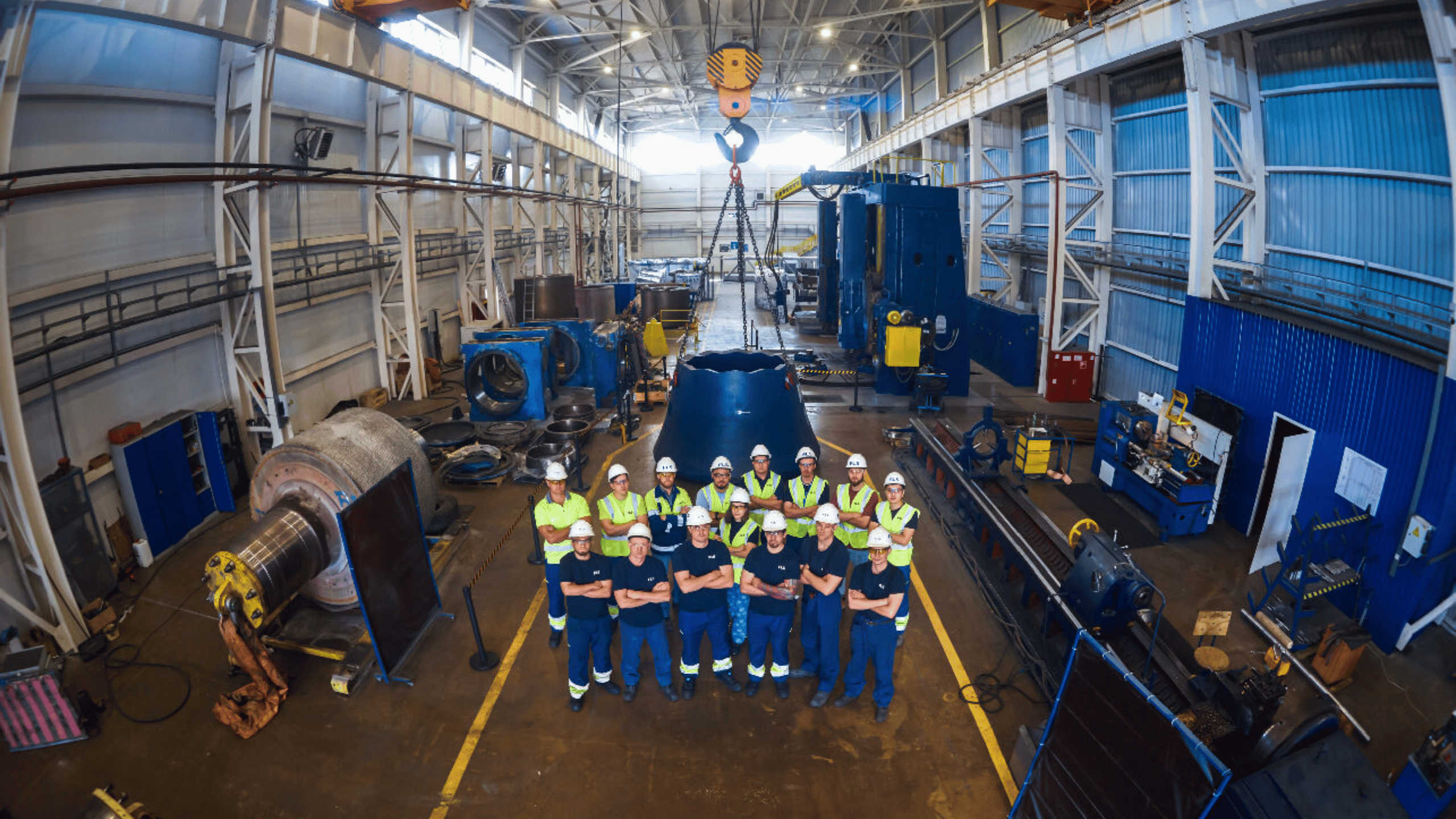

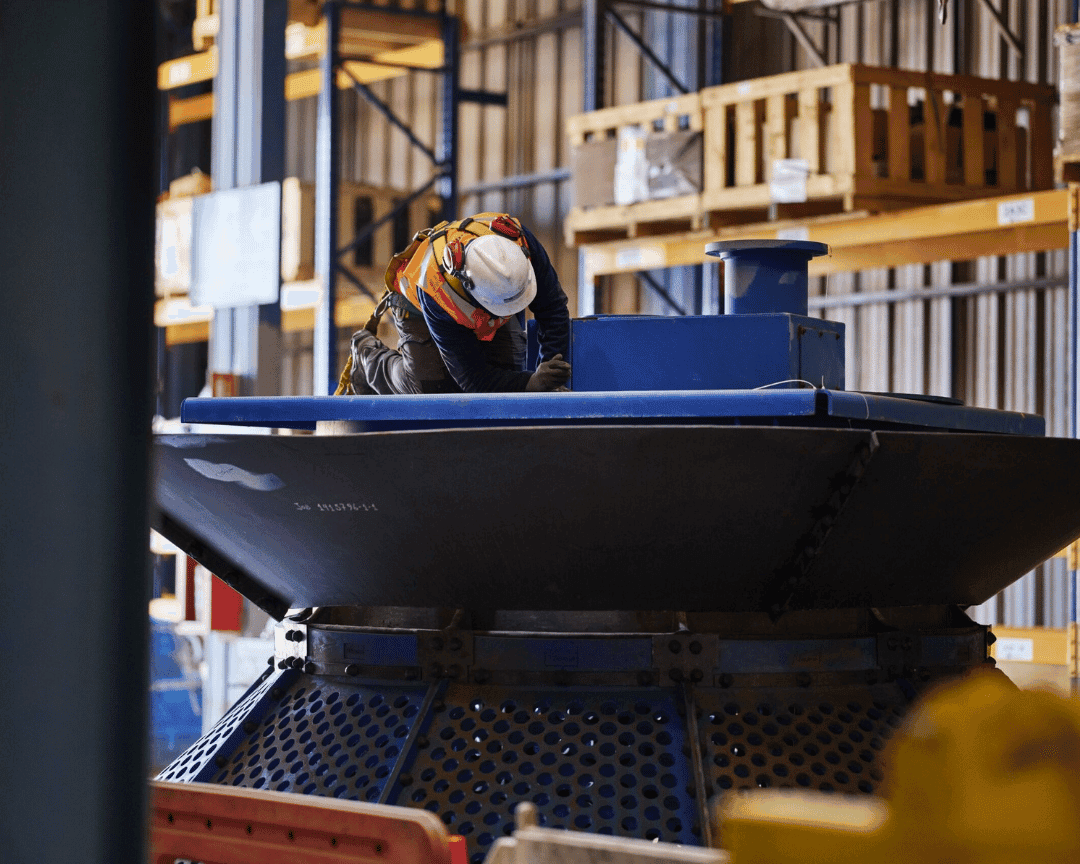

Downtime costs millions. Our local service centers, stocked with key parts, get you back to work fast. With exchange programs, swap worn components on demand—no repair wait. Sign a contract for efficient, safe solutions that keep your operations running smoothly.