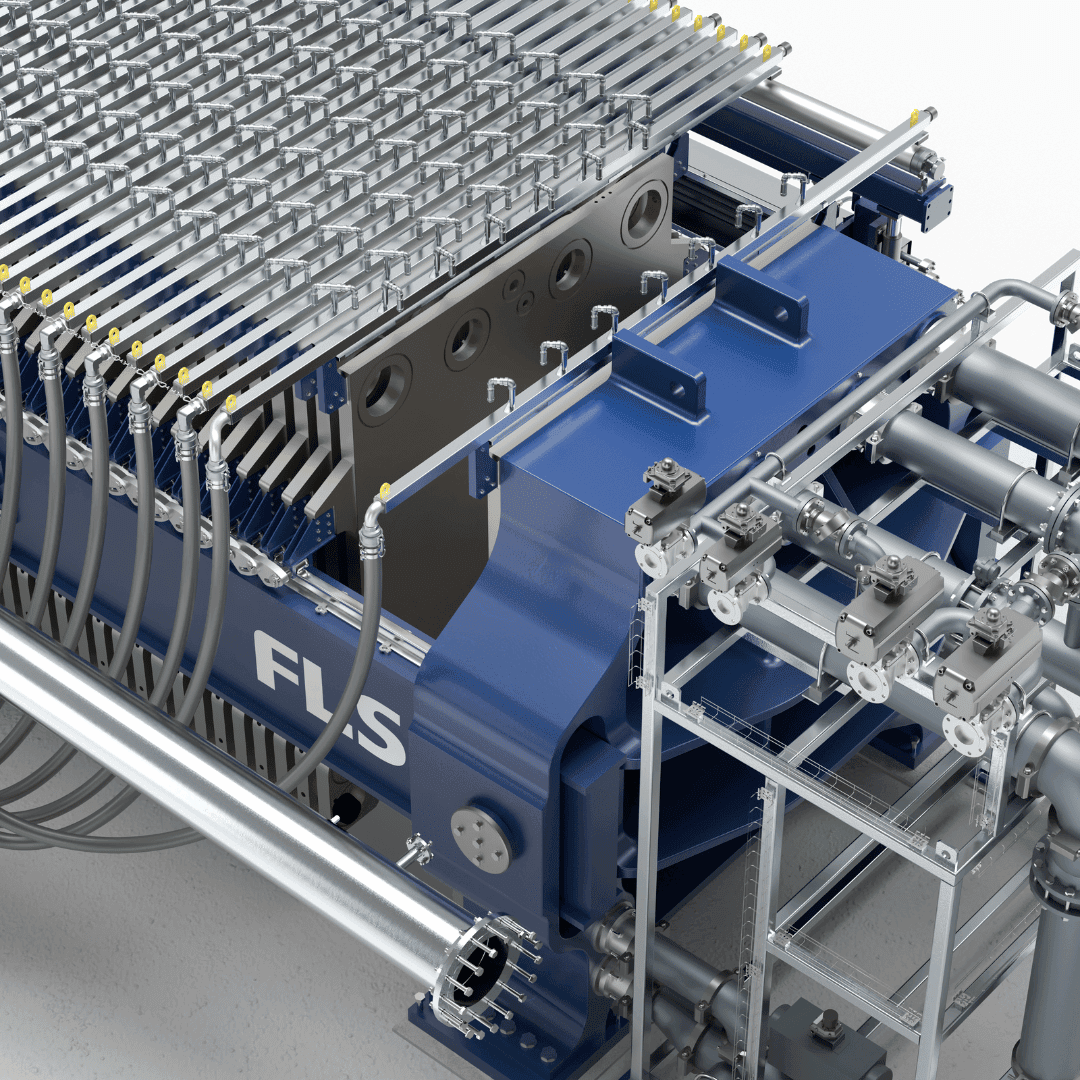

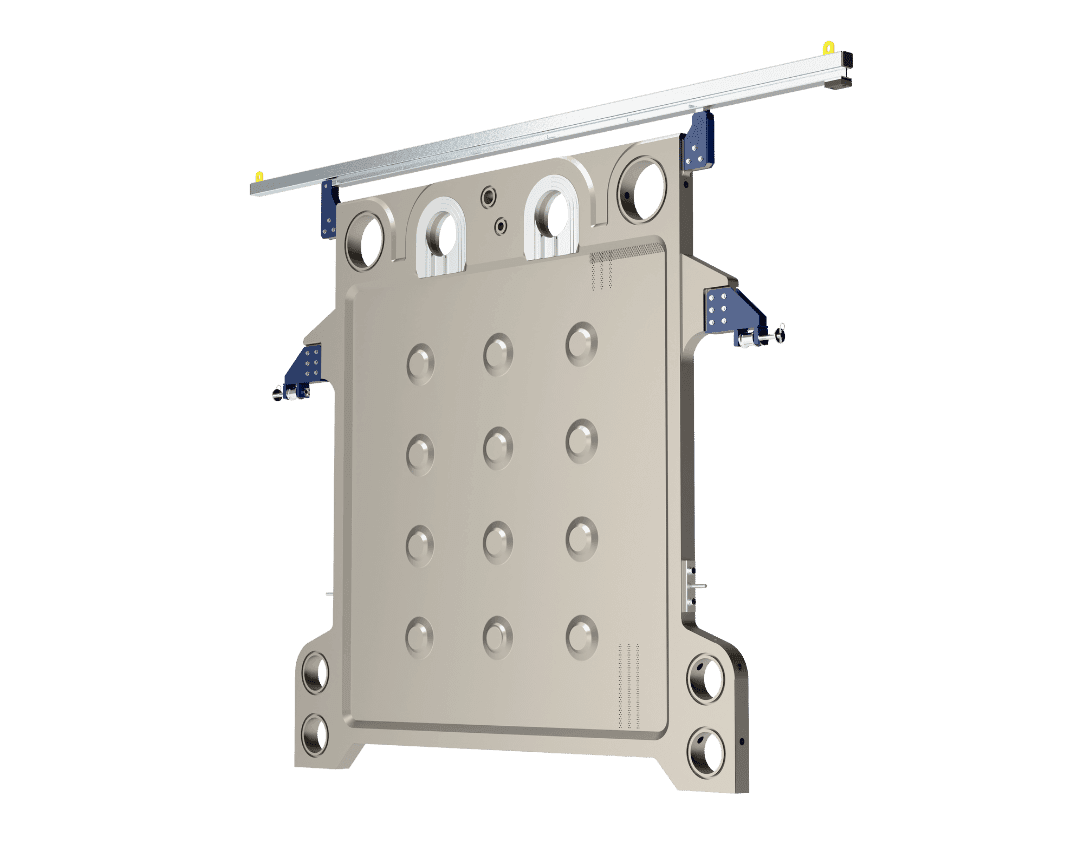

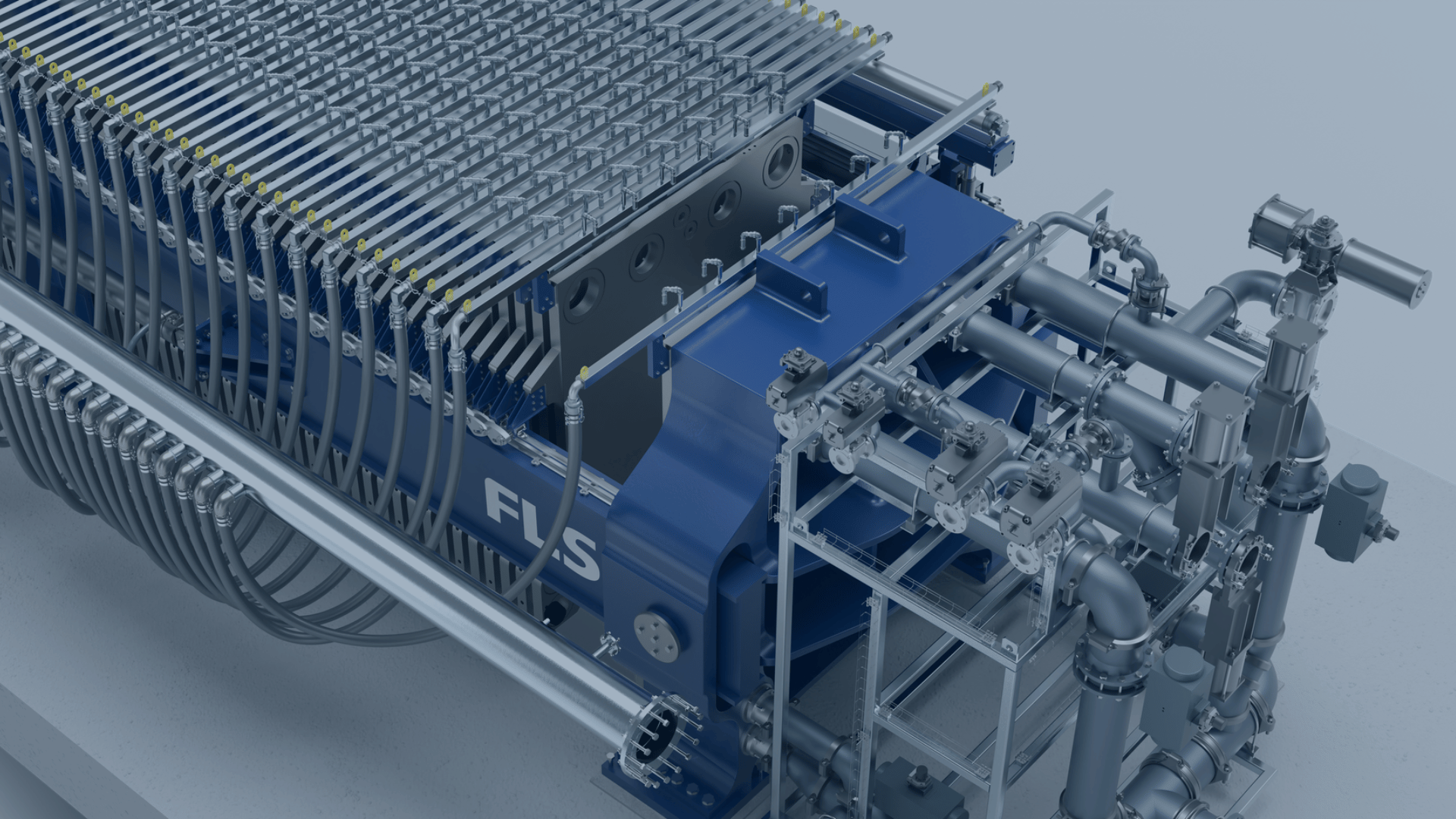

Expert design increases filter life

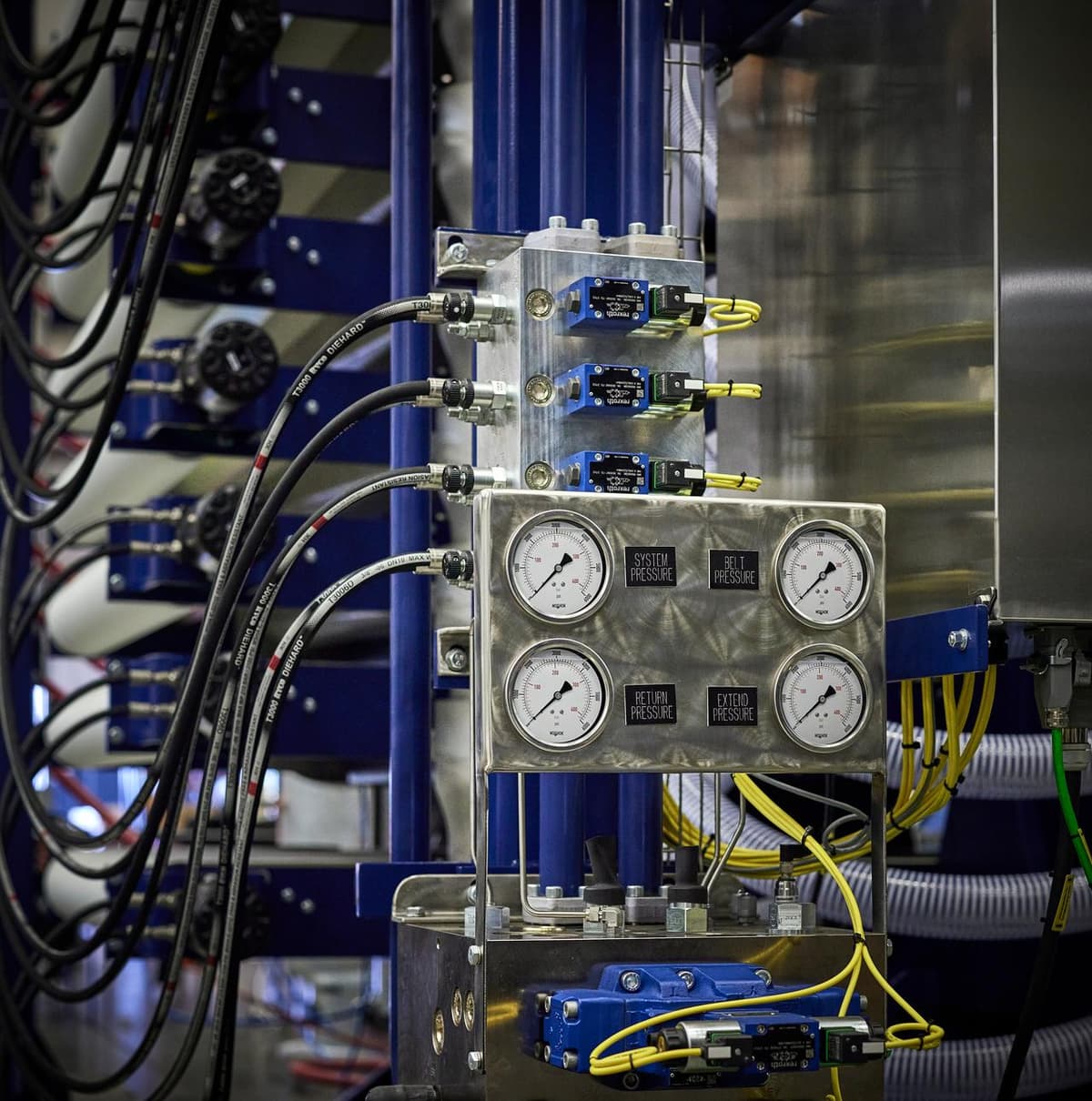

As an OEM with decades of materials, engineering and design expertise, we have filter media selection down to an exact science. Through extensive testing both onsite and at our laboratories, we have regularly been able to achieve >6,000 cycles by selecting the right base materials, yarn styles, cloth weight, density and weave structures.