As ore grades decline, more water is needed to process more material just to keep up with production rates. This creates more water use and tailings to manage. The result is greater environmental impact and footprint and higher costs both for water sourcing in areas of scarcity and for tailings management, which often continues past mine closure.

So, is it possible for you to lessen water consumption in your mine without compromising productivity? The short answer is yes. But it requires creative thinking and challenging the old mining processes to reach that answer.

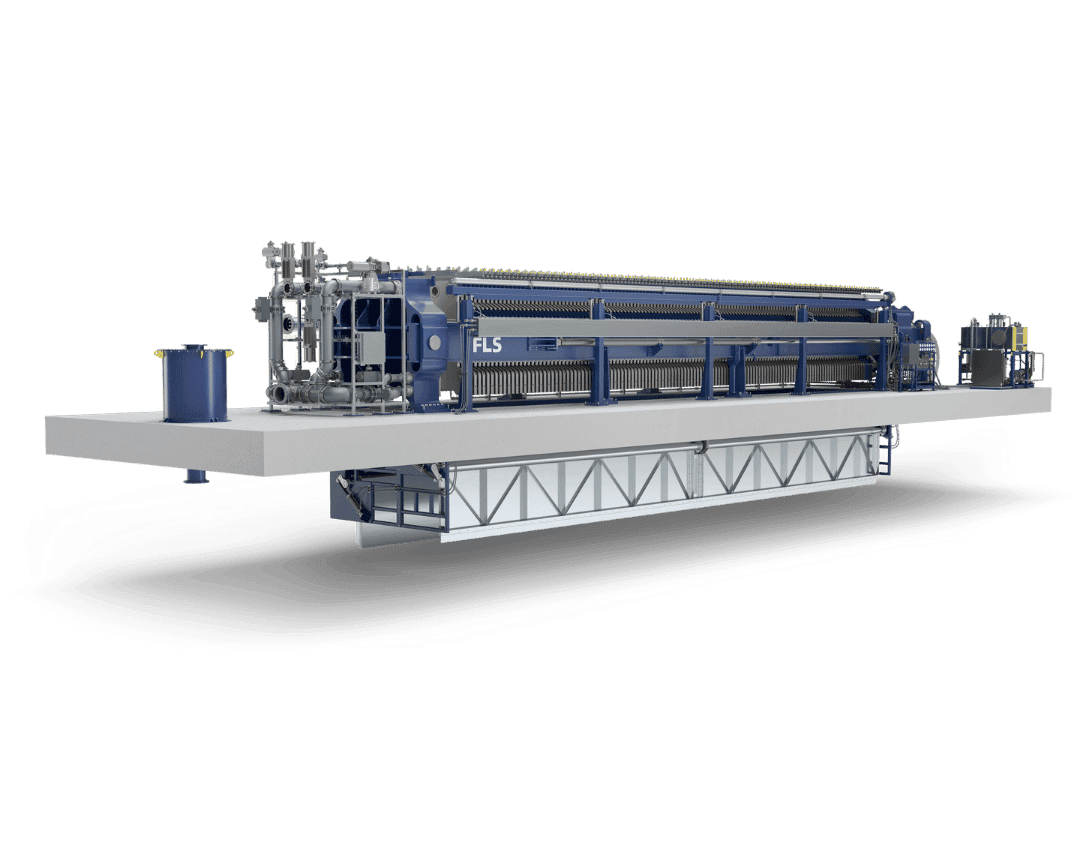

The AFP2525 Automatic Filter Press, for instance, allows miners to recycle and reuse a significant amount water in their operations. As a result, the high-efficiency, large-capacity, dewatering equipment both reduces the need for freshwater intake and cuts costs for the mine site.

The AFP2525, one of FLS leading filtration offerings, achieves 93% availability and up to 95% recovery of process water. This combination of filtering speed and reliability results in the industry’s lowest product moisture per kW. In a typical mine operating at over 21,000 tonnes a day, a filter installation will recover enough process water to fill six Olympic swimming pools every 24 hours.

The AFP2525 filter is easy to maintain, which means costly downtime is minimised. Secondly, the filter is very efficient and operates at high capacity – i.e., it maximises water recovery and is suitable for large-scale mines. Additionally, fast filtration rates and short mechanical times minimise the filter cycle time; this combination of speed and reliability result in the lowest cost per tonne in the industry.