FLS is investing heavily in the digital transformation of its products and ways of working, embracing agile development, co-creation of value with partners within the industry and with third parties and universities.

ECS/ProcessExpert™ (PXP) Advanced Process Control systems now have a module to allow data scientists (at the customer side) to integrate their own AI algorithms into PXP using common tools like Jupyter Notebook. AI Models can be trained in either customer or FLSmidth cloud and deployed into production in the PXP server at the mine.

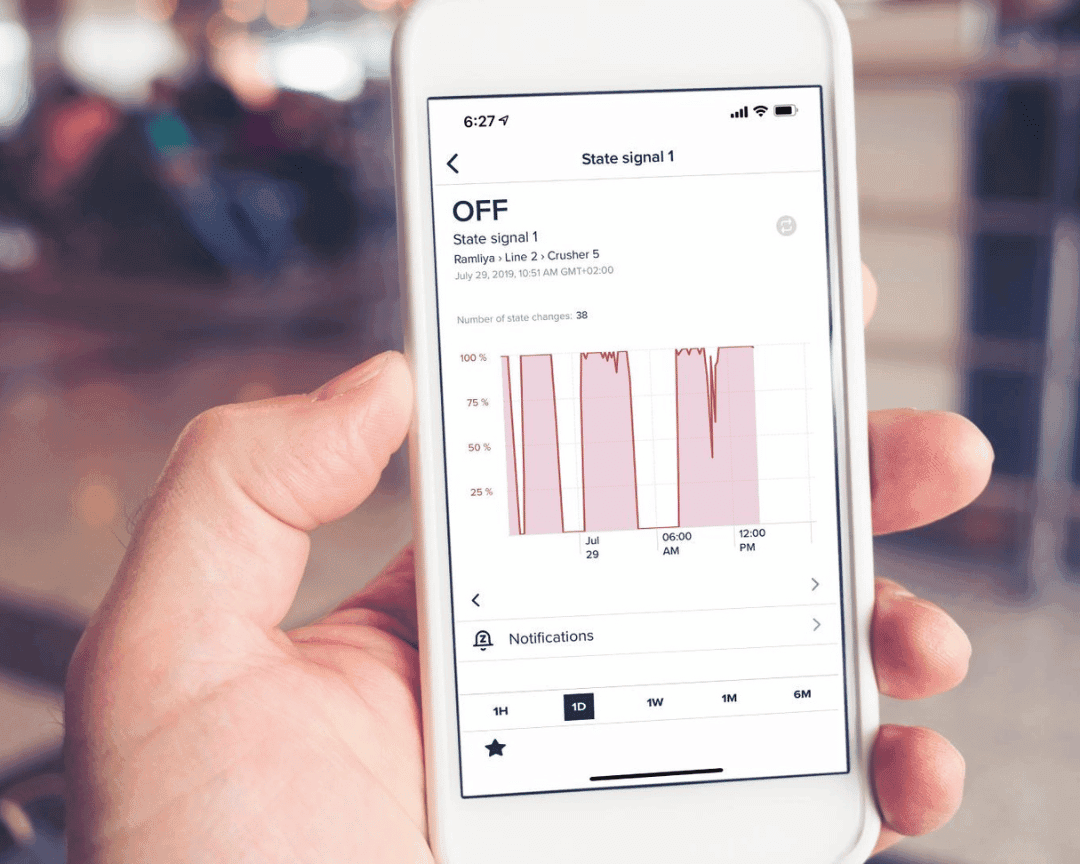

For any Advanced Process Control and AI/ ML models to work we need reliable and smart instrumentation.

We are exploring possibilities of integrating the following instruments with the advanced process control:

- Bridge and boulder detection at crushers

- Crushed rock particle size

- Load IQ on the ball mill

- Moisture sensor on the filter press

- Turbidity on individual filter press plates

- Grade estimation from froth camera

- Digital twin

- Plant optimisation