It was the potential for cost efficiency that convinced Kao diamond mine to implement the KREBS millMAX™ Pump. After initial discussions, the first trial pump - a millMAX 8x6 centrifugal seal (C/S) - was installed in a cyclone feed application (DMS 2 pump 1). Initial results after seven months showed that the millMAX was performing extremely well on the wear side.

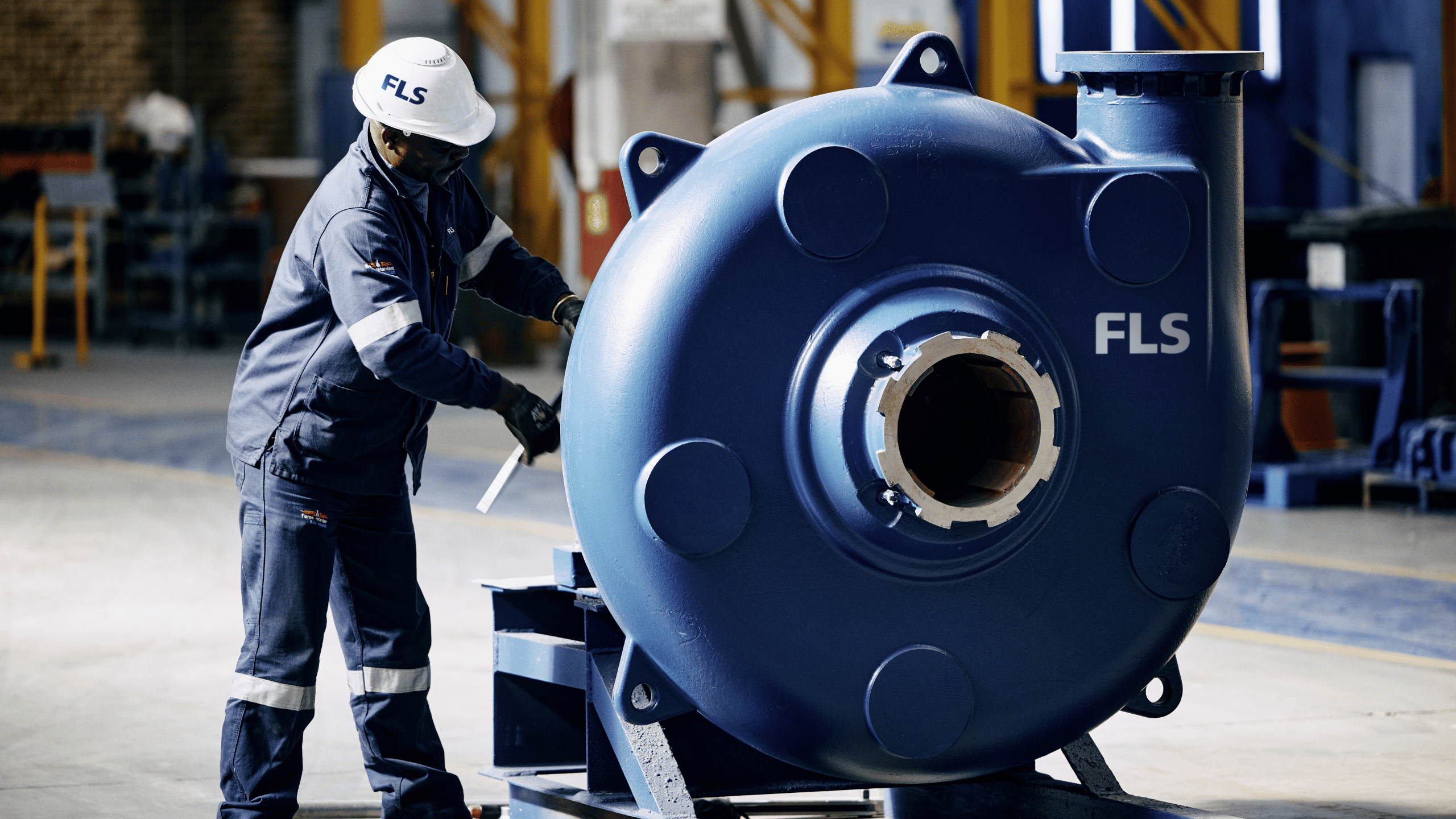

“The results were extremely positive,” reflected Brad Moralee, at the time Head of Product Unit Pumps, Cyclones and Valves at FLS. “Changing out a competitor’s pump in the field, what we call a pump conversion, is a big assignment. It involves building relationships, climbing around in the sumps and dirt on site and doing technical presentations along with on the fly technical problem solving. So once you get the green light, you need to confirm the duty details and measure up the existing installation to ensure that when you begin to install the pump there are no surprises.

“It’s high pressure for us: you are typically given a window of opportunity during a shutdown to complete the change, after which the new pump must run as expected when the plant is re-started."