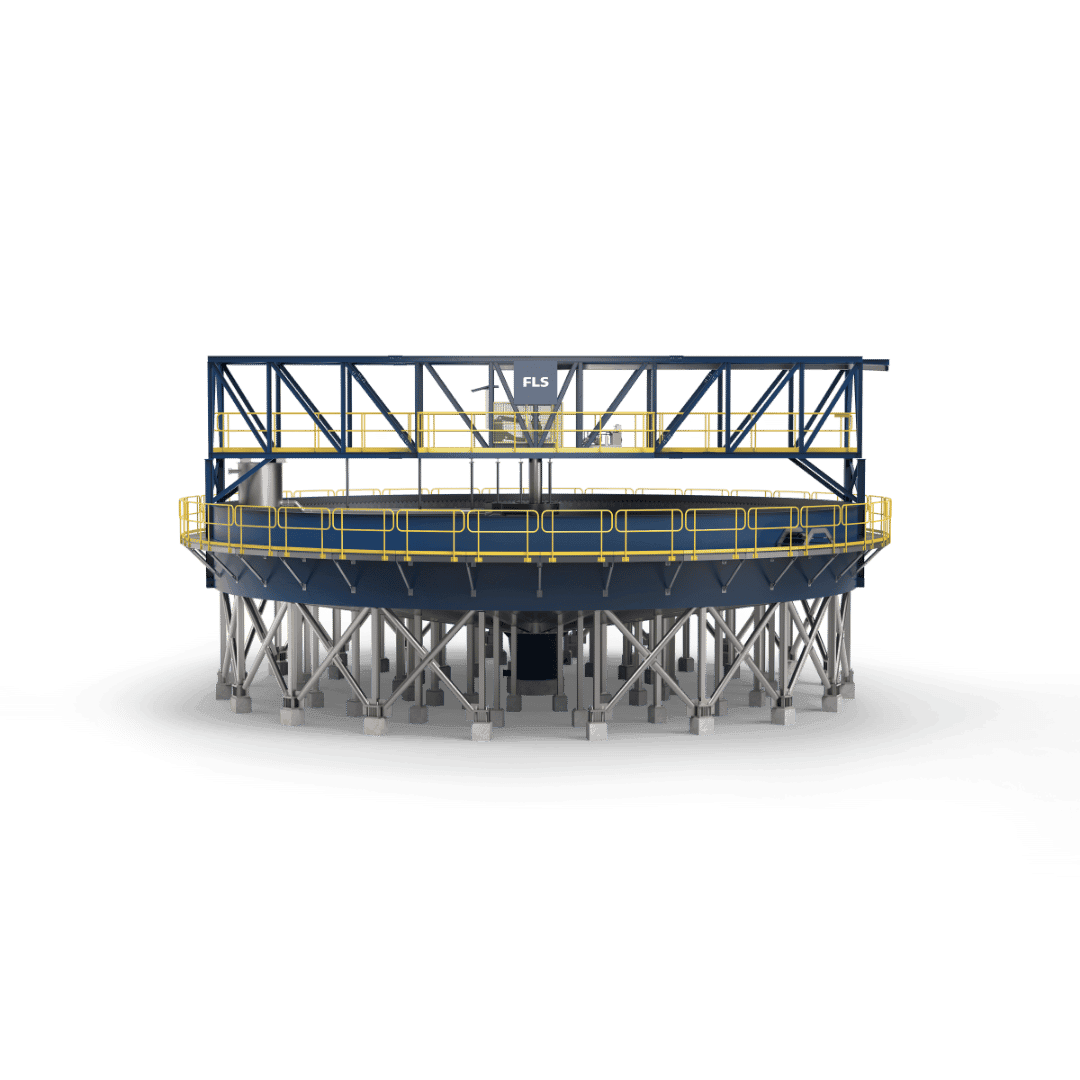

We suggested an upgrade of the existing third-party thickener with an E-DUC® autodilution system and E-Volute™ feedwell, drive and low drag rake mechanism. As a result:

- Underflow density increased from 61% solids (w/w) to 65% solids (w/w).

- The amount of water to tailings fell by 12%.

- Overflow clarity improved from 400 NTU to less than 100 NTU.

- Flocculant consumption was reduced.

This achieved the mine’s goal of becoming a more water-sustainable operation, while also cutting OPEX related to the consumption of water, cyanide, and flocculants. The reduction in water sent to tailings also lowered pumping-related costs.

As less water now reports to the tailings facility, capacity has been extended and operating life extended. Lower water content also helps improve the stability of the tailings dam.