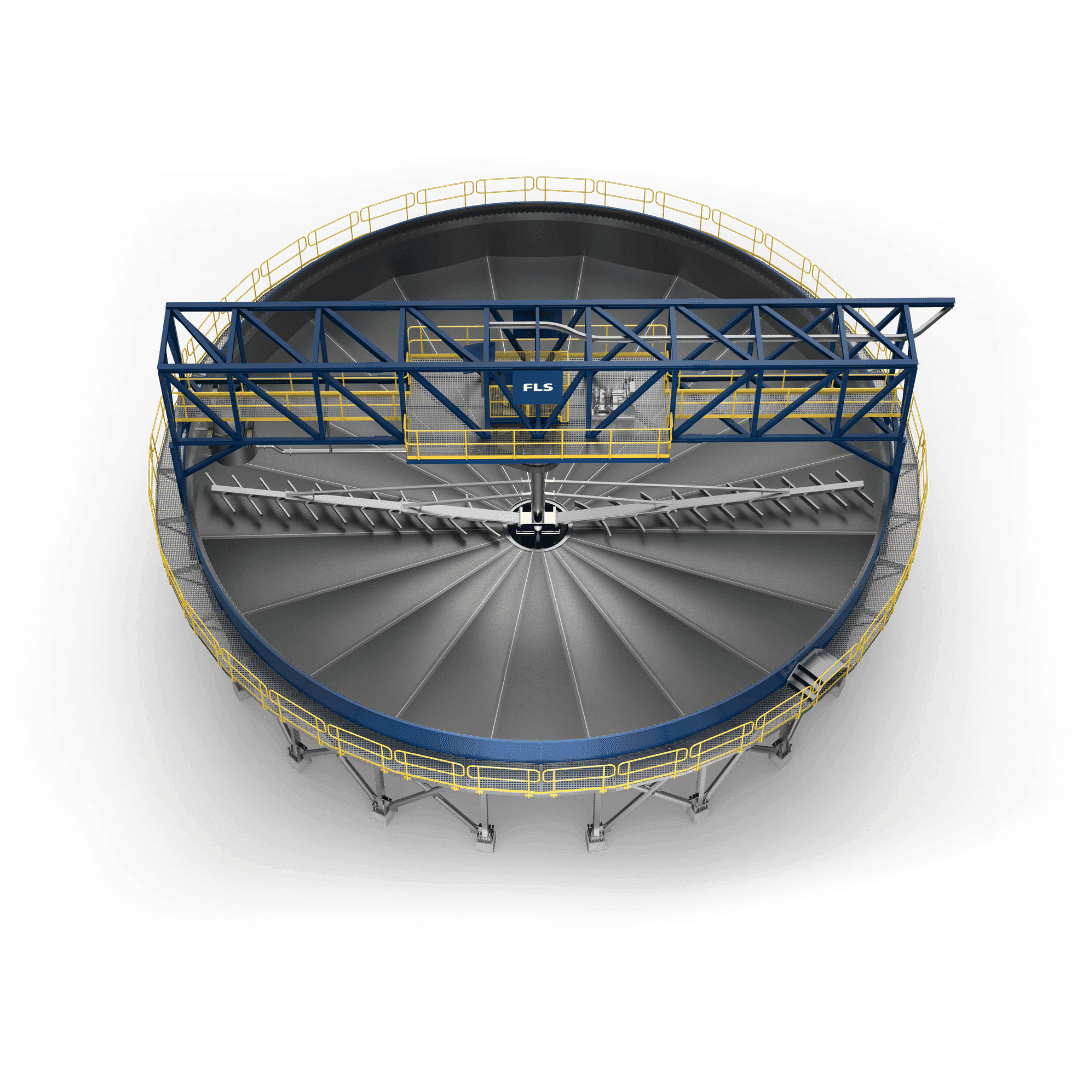

Upgrading the tailings thickener rake at the mine resulted in a number of operational benefits including:

- 10% lower torque.

- Reduced mud rotation and islands.

- 2% solids (w/w) increase in underflow density.

As a result, 8% less water reports to the tailings dam, allowing more water to be recycled and reducing the amount of raw water drawn.

Energy consumption is also lower due to the decrease in torque, as well as reduced water pumping requirements.