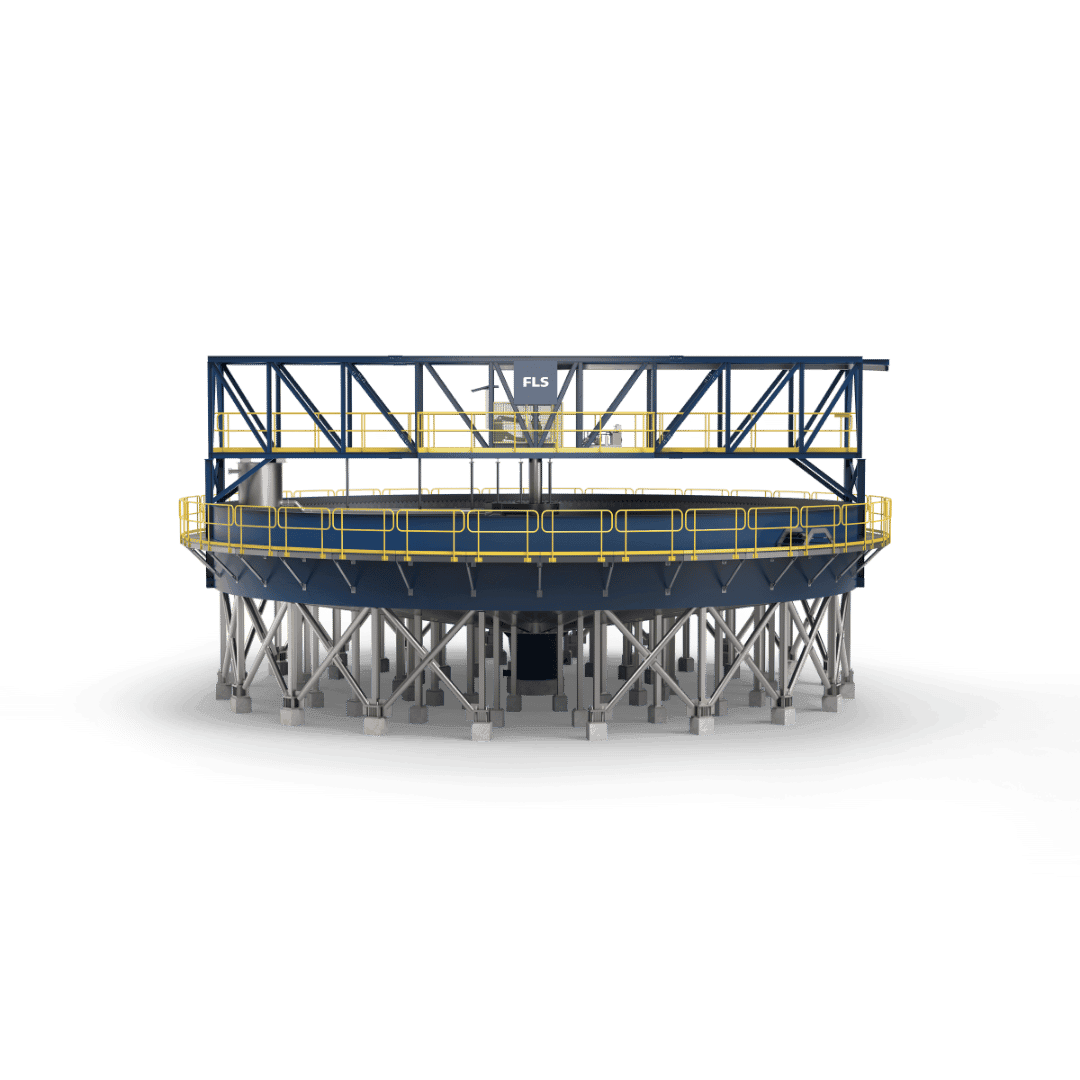

The project involved swapping duties of the leach feed thickener and tailings thickener. We also installed P-DUC powered autodilution mechanisms on both thickeners and an E-Volute™ feedwell on the tailings thickener. As a result:

- Thickener throughput rose from 1060 tph to 1160 tph.

- Leach feed thickener underflow density increased from 54% to 56% solids (w/w). This extends residence time in the CIL circuit, improving recovery without increasing the amount of ore mined.

- Tailings thickener underflow density increased from 54% to 57% solids (w/w), reducing the volume of water reporting to the tailings dam by 11%, and so lowering raw water draw. Less water is also lost to evaporation and seepage.

Overall, the upgrade resulted in a 9% increase in plant throughput – allowing for reduced fixed cost per ounce – while contributing to a more water-sustainable process.