A Kazakhstan copper mine was suffering challenges caused by insufficiently dewatered tailings. This was impacting the stability of the tailings dam and required an earlier-than-planned expansion of the tailings storage facility (TSF); it also increased water lost to tailings and thus the mine’s raw water consumption.

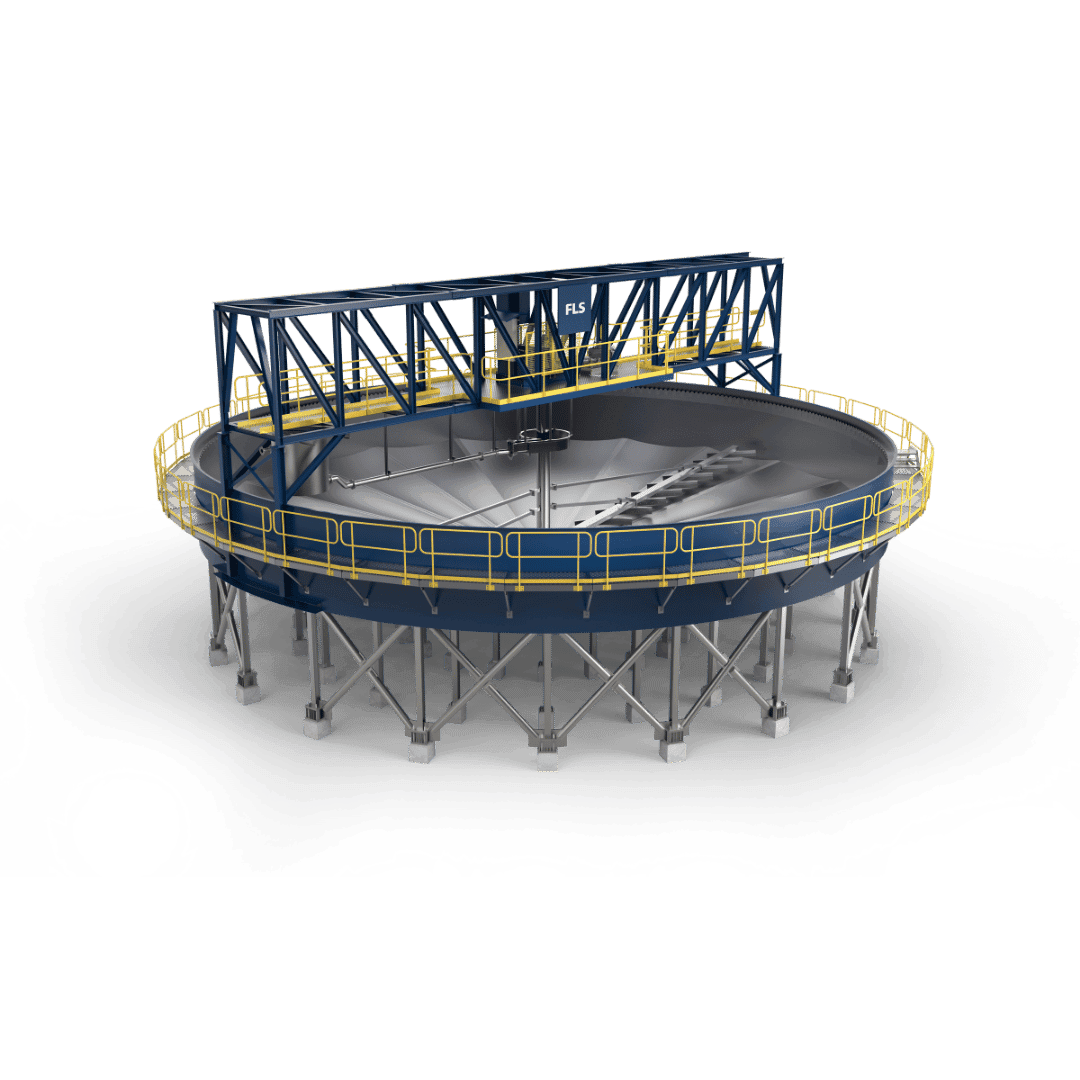

We were approached to supply paste thickeners that would deliver underflow densities in excess of 68% solids (w/w). We responded by accelerating development of our spiral rake paste thickener system and successfully delivered three systems to the mine’s second plant. The upgrade achieved:

- Increased underflow densities of between 66% and 70% solids (w/w)

- A 15% increase of water recovery at the plant

- A 15% reduction in tailings volume

- Reduced short-circuiting in the thickener mud bed; more consistent mud bed residence time

- Maximised deposited tailings density and better utilisation of available TSF footprint

The overall result is a tailings facility that is safer, easier, and more economical to operate and control.