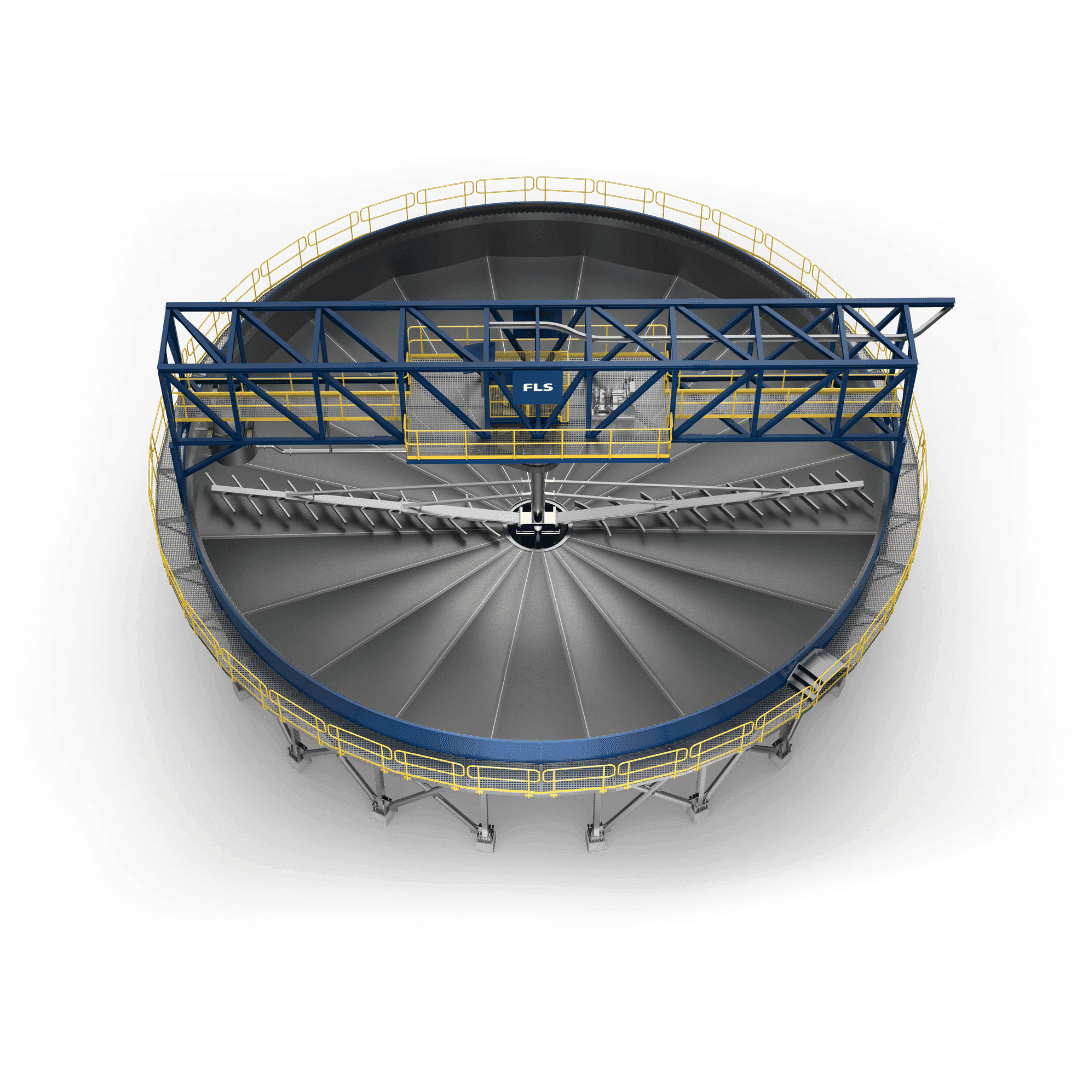

To achieve the mine’s objectives, we installed an E-DUC® autodilution and E-Volute™ feedwell system on the tailings thickener. The results included:

- An increase in tailings thickener underflow density from 35% to 50% solids (w/w).

- A 46% reduction in water going to tailings.

- A 40% reduction in flocculant consumption on a gram/tonne basis.

- Significant savings in cyanide lost to tailings.

- A reduction in pumping and energy costs.

The upgrade also cut particulate content in the recovered process water. This reduced the amount of scale inhibitor required for water treatment by 35%. Cleaner process water also helps maximise gold recovery in the Knelson concentrator by reducing the risk of blockages in the concentrator capillaries.

The overall result is a more cost-effective and sustainable gold recovery process. The mine now uses about 80% recycled water in its process, with fresh water draw restricted to a minimum, while at the same time delivering substantial process improvements.