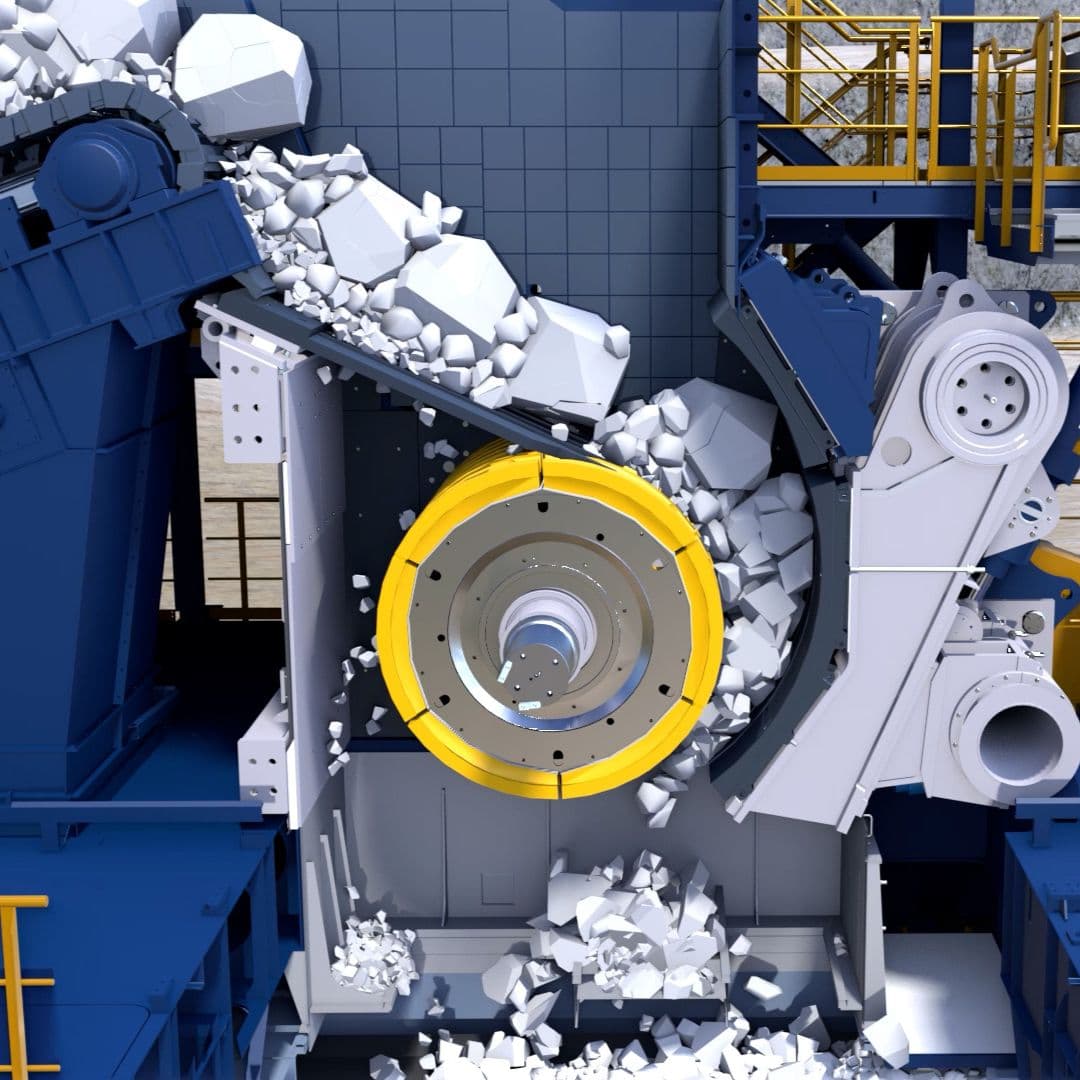

The ERC patented crushing technology is also significantly more compact than alternative crushing systems, making it ideal for mobile and semi-mobile in-pit crushing applications.

The site trials took place at a mine in New South Wales, Australia. The ERC delivered on the key drivers achieving:

- 10% higher throughput (compared to the existing BK 63-75 gyratory jaw crushers).

- Improved product P80 of 110 mm at a CSS of 90 mm (compared to 110 mm to 125 mm).

- Up to 50% reduction in specific power consumption.

The design of the ERC also offers greater flexibility when it comes to gap setting, as well as adjustment for liner wear and the presence of tramp metal/uncrushable materials. Meanwhile, lower energy consumption delivers reduced CO2e emissions. The bottom line is a crushing solution that delivers improved operational safety, efficiency, productivity, and environmental sustainability.