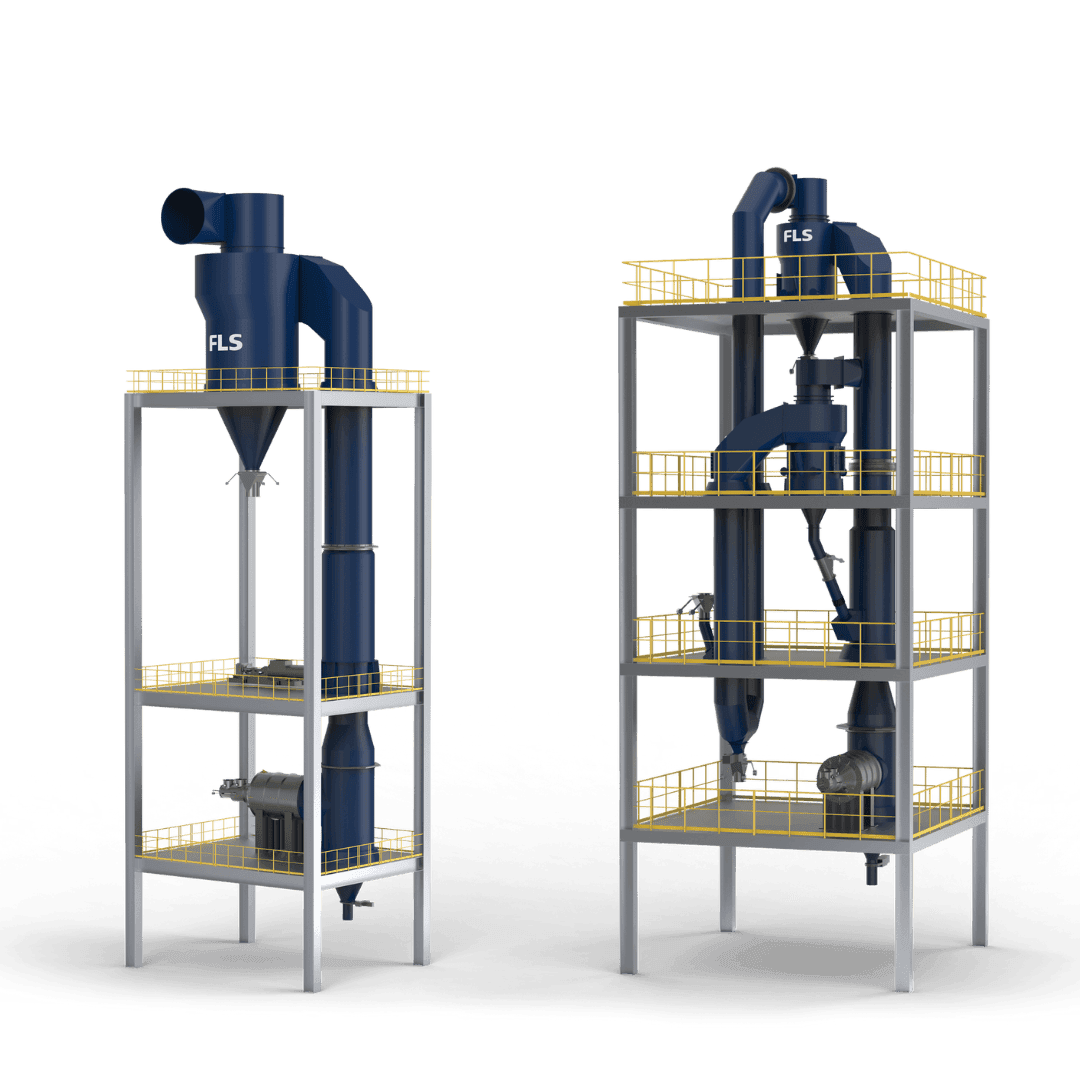

Our flash dryers

FLS flash dryers/heaters use gas suspension drying (GSD) technology to various fine materials. Offering throughputs between ≤1.0tph up to ≥750tph, our dryers can operate as stand-alone solutions or as an integrated system with other pyro-equipment, such as rotary kilns, indirectly heated rotary kilns, gas suspension calciners, or multiple heath furnaces, to improve overall efficiency. We can accommodate a wide range of fuels, including hydrogen firing, and can include an optional back mixer to adjust final product moisture.