HP-PA automatic pellet press

Perfect quality of the pressed pellet - The HP-PA produces high quality pressed pellets with a smooth surface necessary for an optimal XRF results. The HP-PA achieves the desired uniformity and density of each individual pressed pellet with maximum reproducibility.

Avoidance of contamination - In the standard version of the press, the counter pressure plate of the die is cleaned with a brush which rotates in alternate directions. As an option, a Mylar film device effectively prevents material particles from becoming fixed to the counter pressure plate.

Program-controlled pelletizing for high reproducibility and throughput - All parameters necessary for the pelletizing process such as total pressing force, incremental increase and decrease of pressing force and pressure holding time can be preset. They are clearly presented on the HMI control panel and can be easily adjusted. Due to the program-controlled automatic sequence, every sample is processed identically and is not subject to human error. Furthermore, the automatic sample operation guarantees a high sample throughput whenever required.

Modular design - Due to their modular design, the HP-MA and HP-PA can be easily linked together or combined with other components. The modular design guarantees numerous combinations with other machines. It is possible to combine, e.g., two individual machines with manual feed and manual discharge, to add an automatic connection with conveyor belts, or design a fully automatic operation with an airtube receiving station and direct connection to an XRF spectrometer. Furthermore, the HP-MA and HP-PA can be easily integrated into a largescale robot automation.

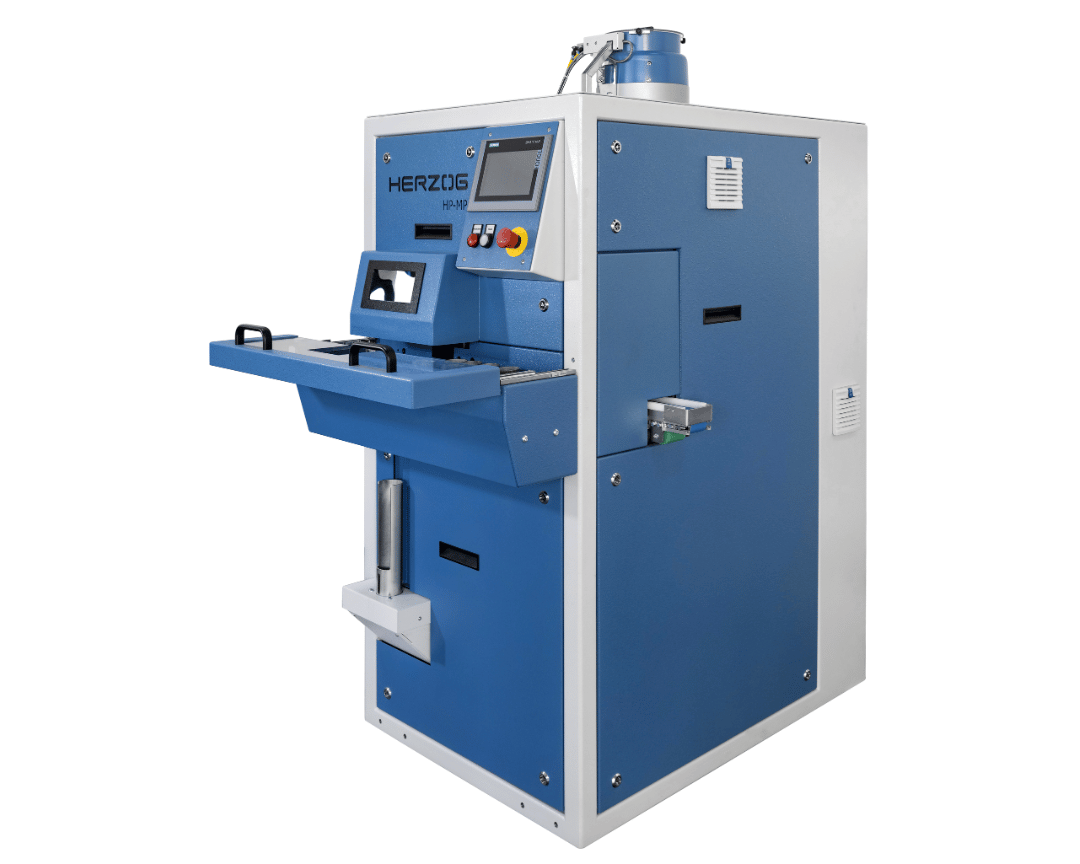

HP-MP automatic grinding mill and pellet press

Compact and easy to operate - The HP-MP is the state-of-the art solution for grinding of powder material and preparation of pressed pellets for XRF and XRD analyses. The compact dimensions, the wealth of functions and effortless operation make the HP-MP the perfect choice for QC laboratories. The HP-MP is versatile and ready for different configurations: It can be used as a stand-alone machine with optional magazine function, as part of a linear automation or component of a robot cell. The HP-MP contains a wide variety of unique features to cover the specific needs of quality control and assurance. Thorough cleaning of all contact surfaces, blind dosing and other processes are used to effectively avoid cross-contamination between subsequent samples. The powerful hydraulic module with continuously adjustable press forces up to 200 kN is suitable even for challenging analytical tasks. The HP-MP can automatically retain a sample aliquot for further analyses. Grinding and pelletizing can be carried out independently.

Stand-alone configuration - High priority was the design of a versatile machine that is deployable in many different configurations. As a stand- alone machine, the HP-MP can be operated with an input and output device where the operator inserts a single cup and removes the pressed pellet. As an option, a 23-position-magazine is available to allow automatic batch processing of samples. The prepared pressed pellets are collected in an output magazine attached to the side of the machine. As a matter of choice for the operator, the cup can be returned empty to the magazine or filled with retained sample material for further sample processing or analysis.

Designed for easy automation - In a linear automation, the HP-MP receives the sample from, e.g., an input magazine, pneumatic airtube station (type HR-LA), crusher (HP-CA) or gravimetric dosing unit (HR-WA). Pressed pellets are automatically transported to various analysers such as XRF and XRD. Several HP-MPs can be combined and interconnected with other components via conveyor belts. In a robot cell, the HP-MP is positioned with the side wall facing towards the robot. The robot inserts the sample cup and removes the pressed pellets via short input and output belts. This makes it possible for the operator to comfortably use the machine for manual operation from the front side. Simultaneously with robot operation, e.g., special samples can be entered via the manual input flap or the 23-position magazine.

Tool Condition Monitoring - The HP-MP is ready for smart industry solutions enabling tool condition monitoring and predictive maintenance. Integrated sensory technology allows the online monitoring of the grinding performance as well as wear of swing aggregate and grinding set. This powerful tool, in combination with the PrepMaster Analytics software, makes it possible to assure reproducible sample preparation conditions for more accurate analysis. In addition, the HP-MP allows the fully automatic determination of the specific grinding energy of a material. This enables QC laboratories to easily and immediately determine the grindability of their sample materials.

Full control of the pelletizing process - The hydraulic unit ensures a controlled and reproducible pelletizing process. All parameters are easily adjustable to allow finetuning for each material and analytical approach. The operator can directly change the total pressing force (50- 200 kN), the incremental increase of the pressing force and the pressing holding time. Each pelletizing cycle can be monitored by the clearly laid-out HMI panel of the HP-MP or the PrepMaster screen. Using the dosing device of the HP-MP, the operator can choose between two different sample volumes for production of pressed pellets. The HP-MP can process 40 mm or 51.5 mm rings by default. The thickness of the pressed layer within the ring is automatically monitored so that a warning is issued if there is a lack of material.