Automated, operator-engaged self-cleaning cycle

Triggered via the HMI and controlled by the PLC, the cell executes the self-cleaning sequence. It washes sludge from the cathodes, collects it in the lower trough and then flushes the precious-metal slurry to the sludge pump.

- Approximately 300 hours per year less cell servicing and maintenance

- About USD 42,000 annual labour cost saving versus a competing electrowinning cell

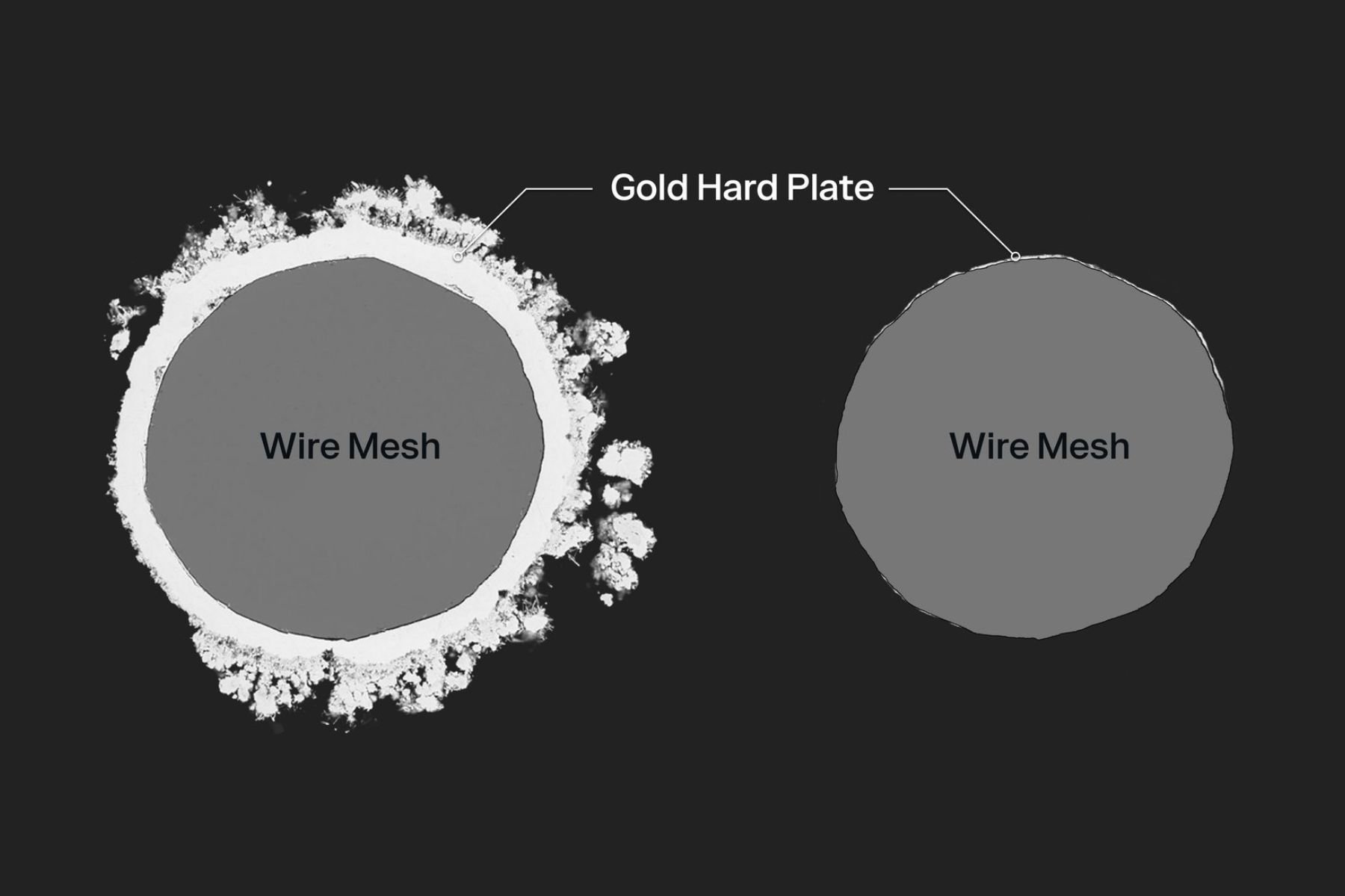

Hard-plate removal that limits inventory lock-up

Traditional cells typically hard-plate about 1.25% of annual production onto the cathode mesh. This ties up cash, adds refinery charges and drives mesh replacement. The SummitPro’s operator-engaged hard-plate removal cycle reduces gold lock-up to about 0.008% and eliminates mesh refinery and replacement costs.