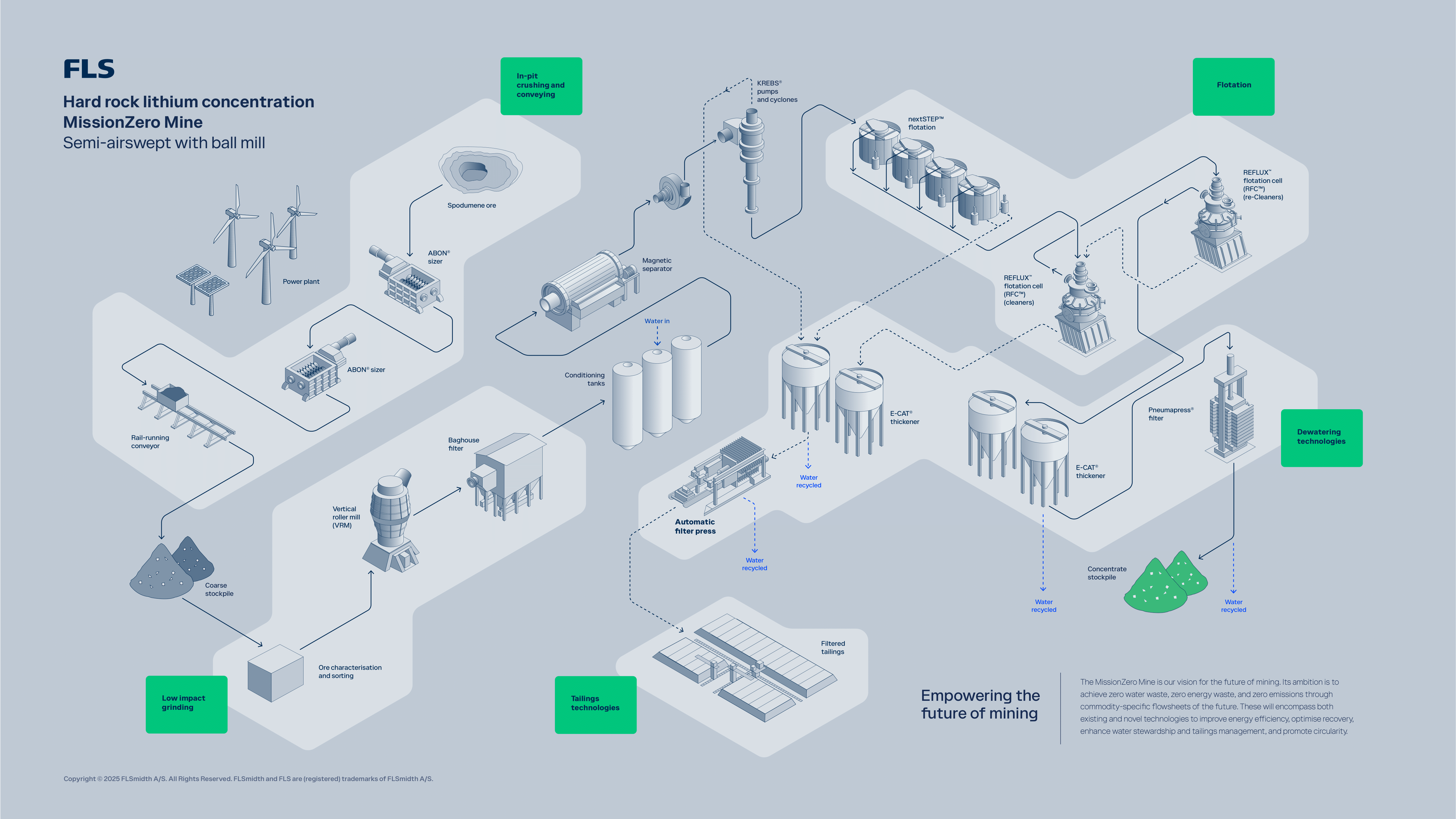

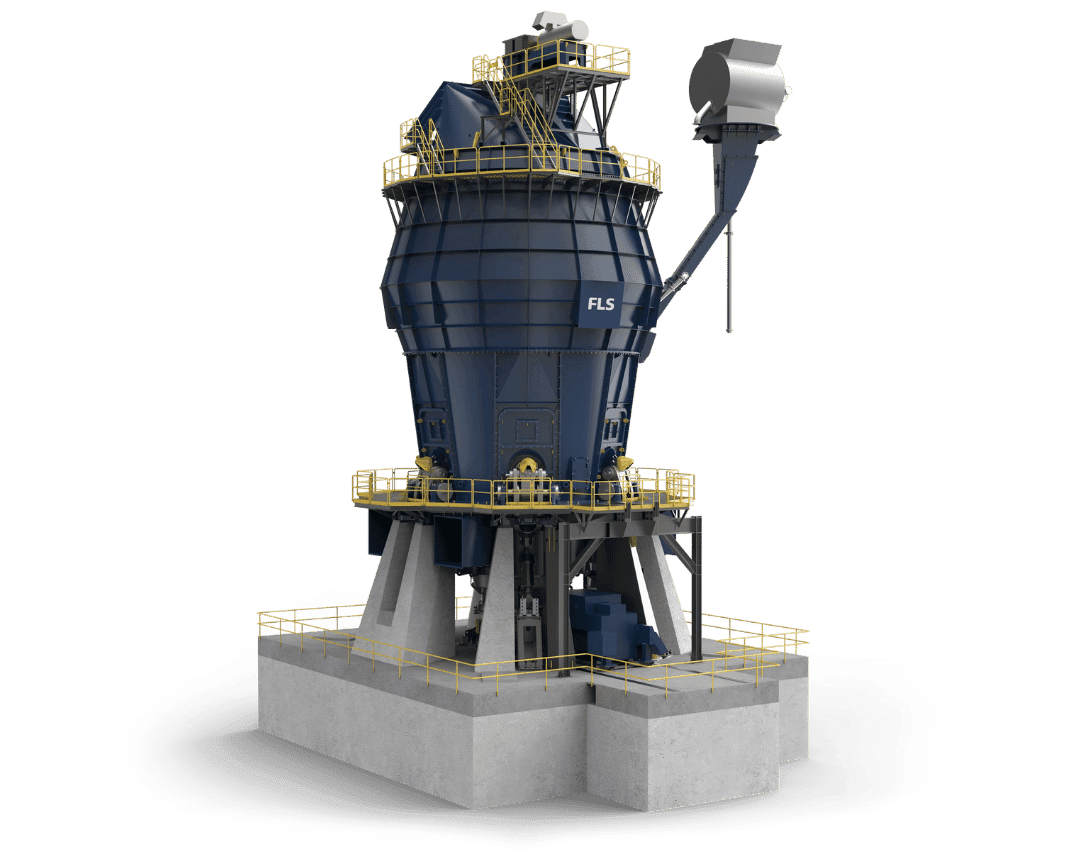

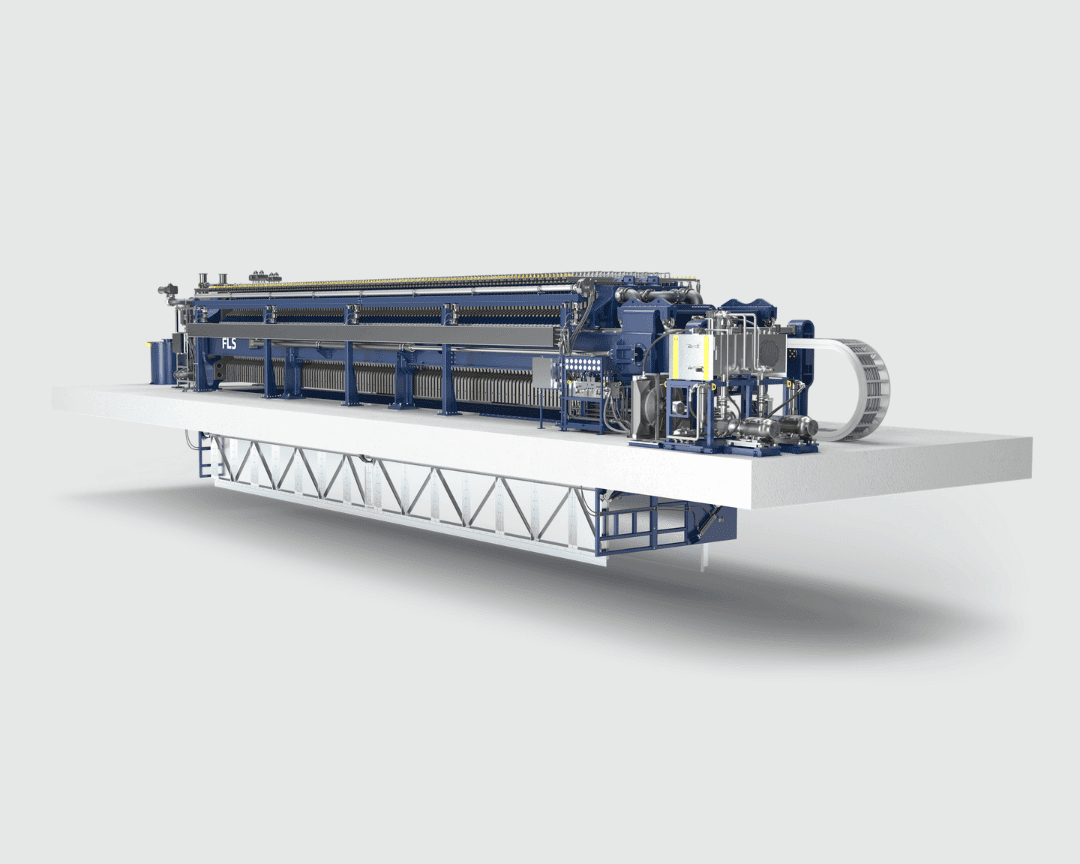

The MissionZero Mine hard rock lithium (spodumene) flowsheet builds on conventional whole-ore flotation circuits by incorporating various innovative technologies in the layout. Spodumene ore is crushed using ABON® Sizers before being sent for ore characterisation and sorting ahead of grinding in an FLS VRM. From the mill, material moves through a magnetic separation step and onto flotation using nextSTEP™ and REFLUX™ flotation cells. Both tailings and concentrates are thickened using E-Cat high-rate thickeners. The spodumene concentrate is then dewatered in a Pneumapress filter, while the tailings are dewatered using an AFP automatic filter press, generating a filtered tailings product.

In an independently reviewed third-party Life Cycle Assessment (LCA), this circuit demonstrated a 16% lower climate change impact, a 15% lower water scarcity impact, and only 3% higher costs, compared to a conventional circuit with a wet tailings storage facility. The relative cost of the MissionZero flowsheet compared to the conventional circuit with wet tailings is dependent on the relative cost of water: higher water costs will improve the relative MissionZero Mine cost and make it more attractive financially, as well as environmentally. Compared to a traditional circuit with dewatered tailings, the MissionZero Mine flowsheet reduced the climate impact of hard rock lithium processing by 21% and the water scarcity impact by 11%, while reducing costs by 11%.