MissionZero copper mining

Copper is essential to many facets of modern life and the green transition. Take a wind turbine. These can contain up to 4.7 tonnes of copper. With installed wind power capacity expected to more than double by 2030, that’s a lot of copper. And that’s just one example. Overall, total copper demand is projected to rise between 275% and 350% by 2050, with 1.4 billion tonnes of new copper needed to reach net zero over that time.

This would be a challenge under any circumstances, but the mining industry is also going through a green transition, working to reduce its environmental impacts. Consider that more than 50% of copper production occurs in water-stressed regions, and climate change may only further exacerbate water scarcity. The risk this poses to copper production is clear. Similar concerns are present with energy consumption (and the related carbon emissions) and tailings management.

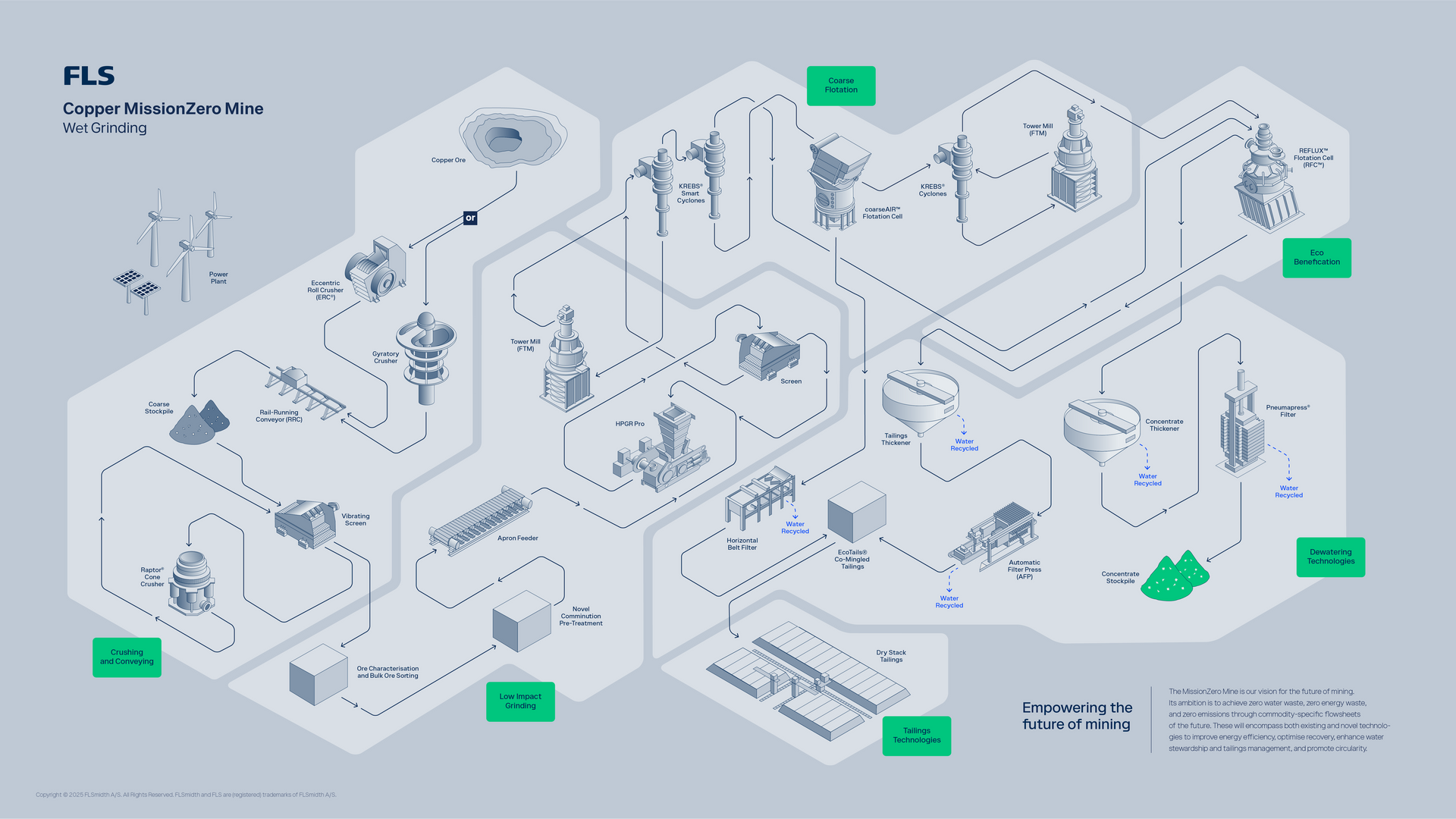

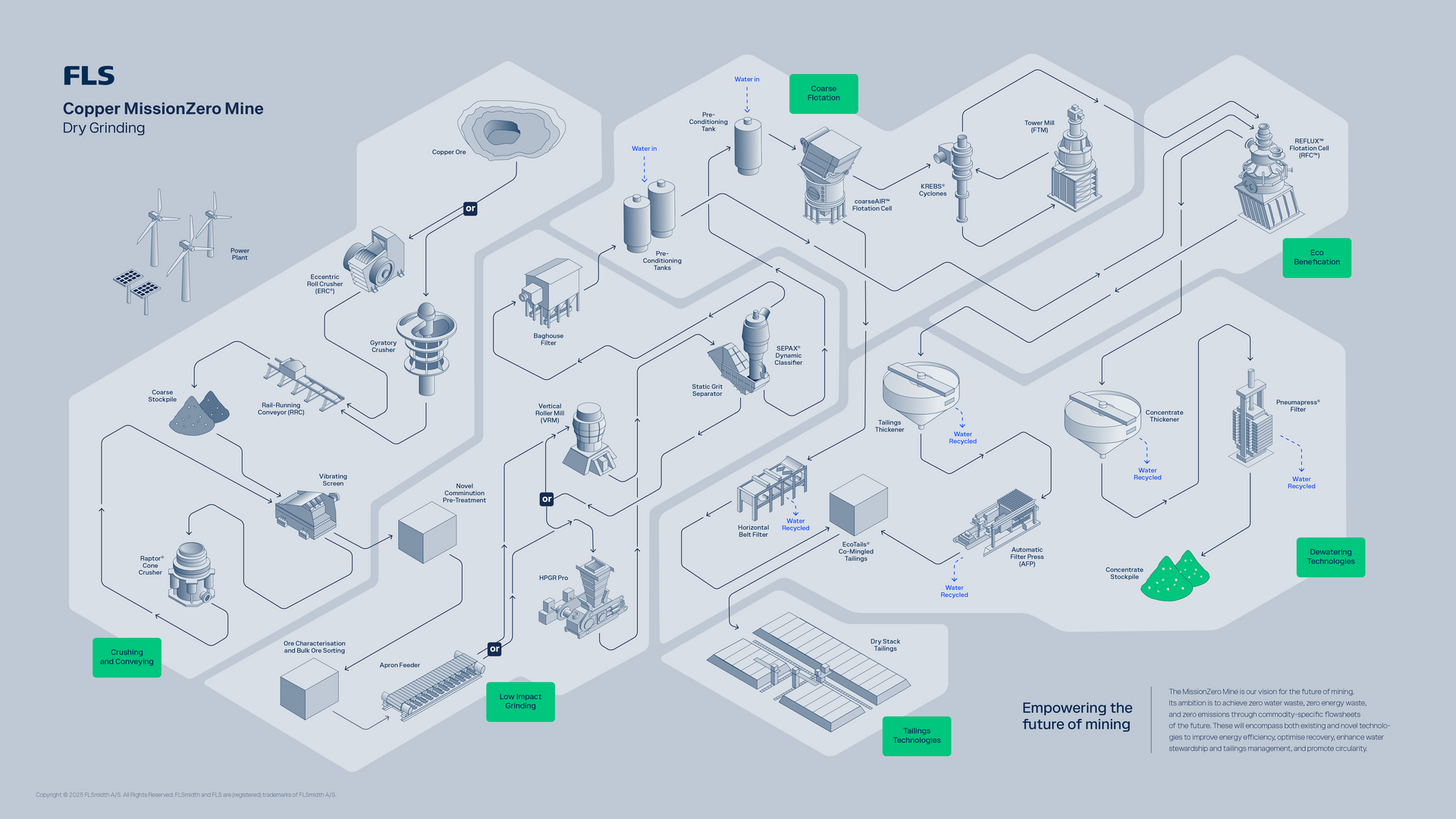

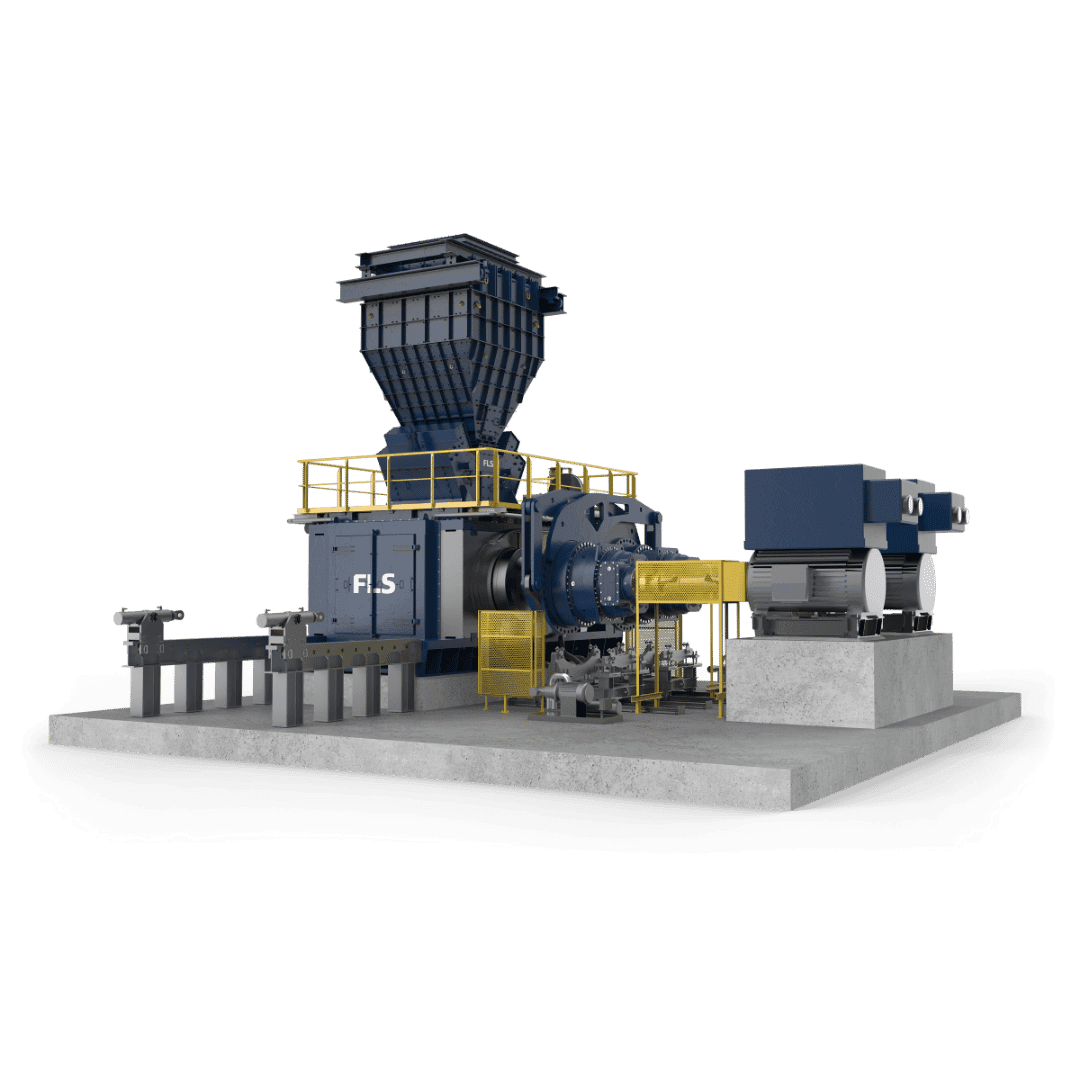

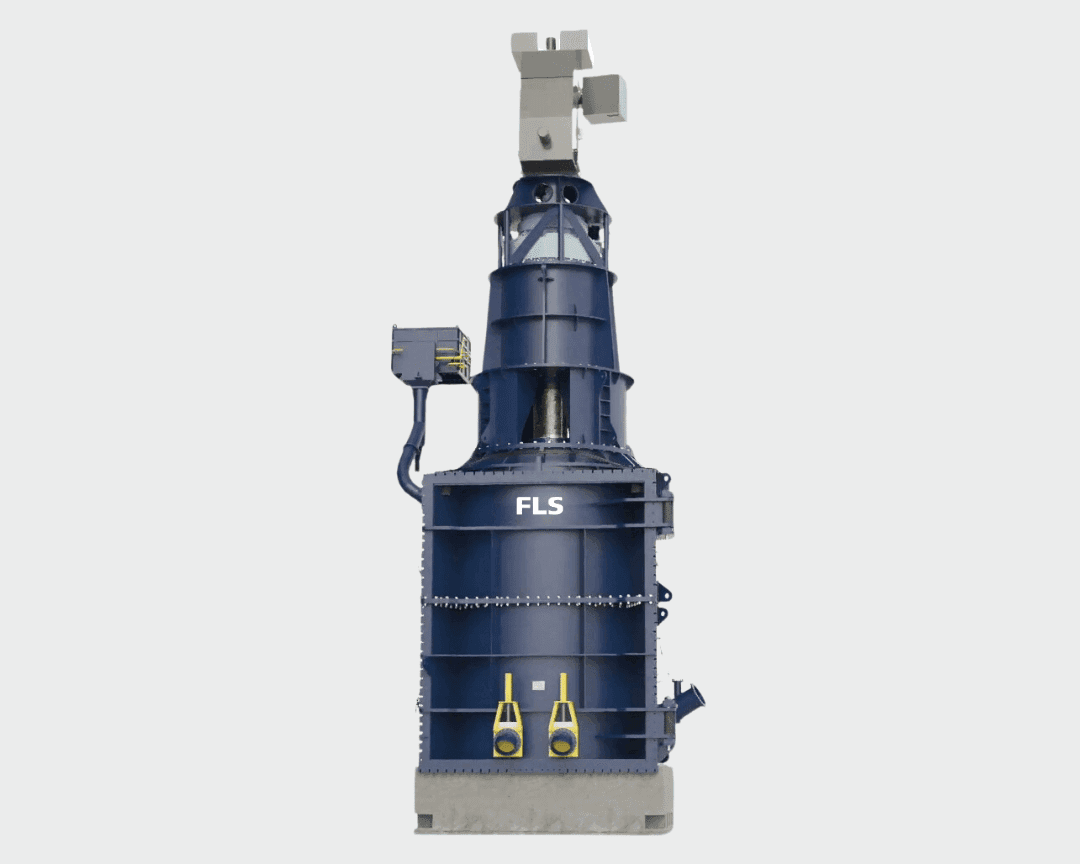

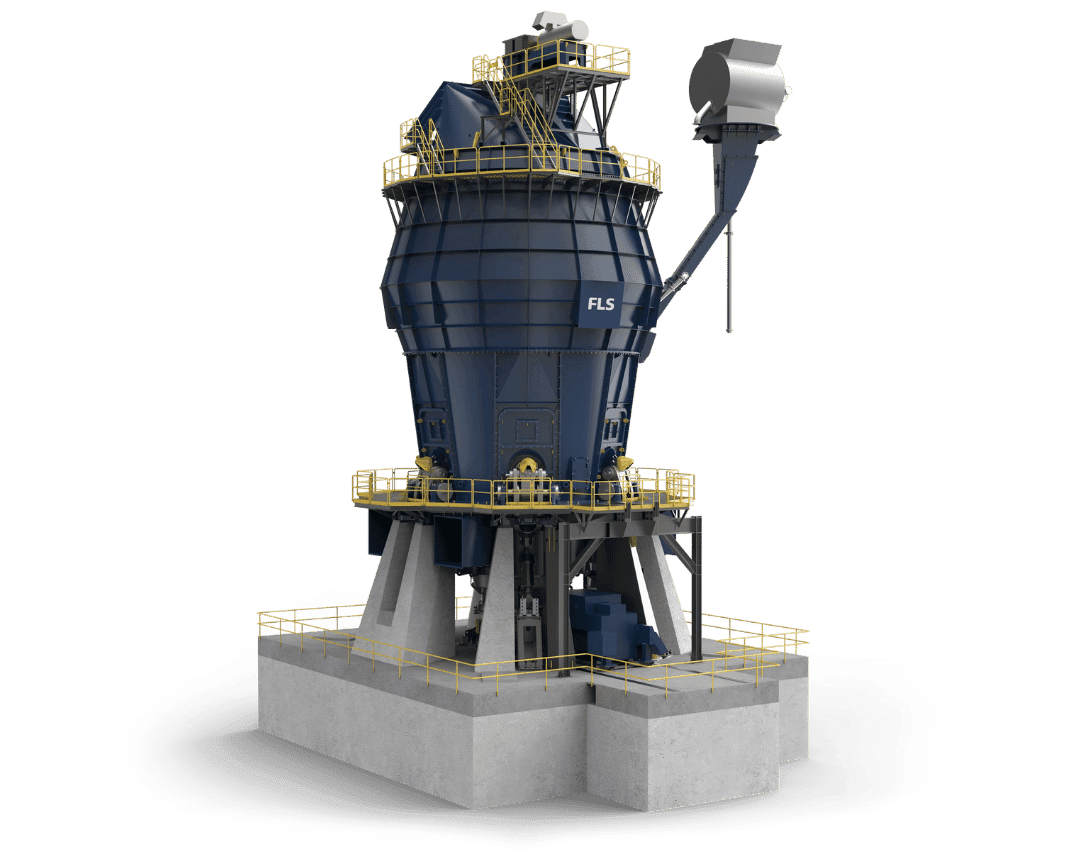

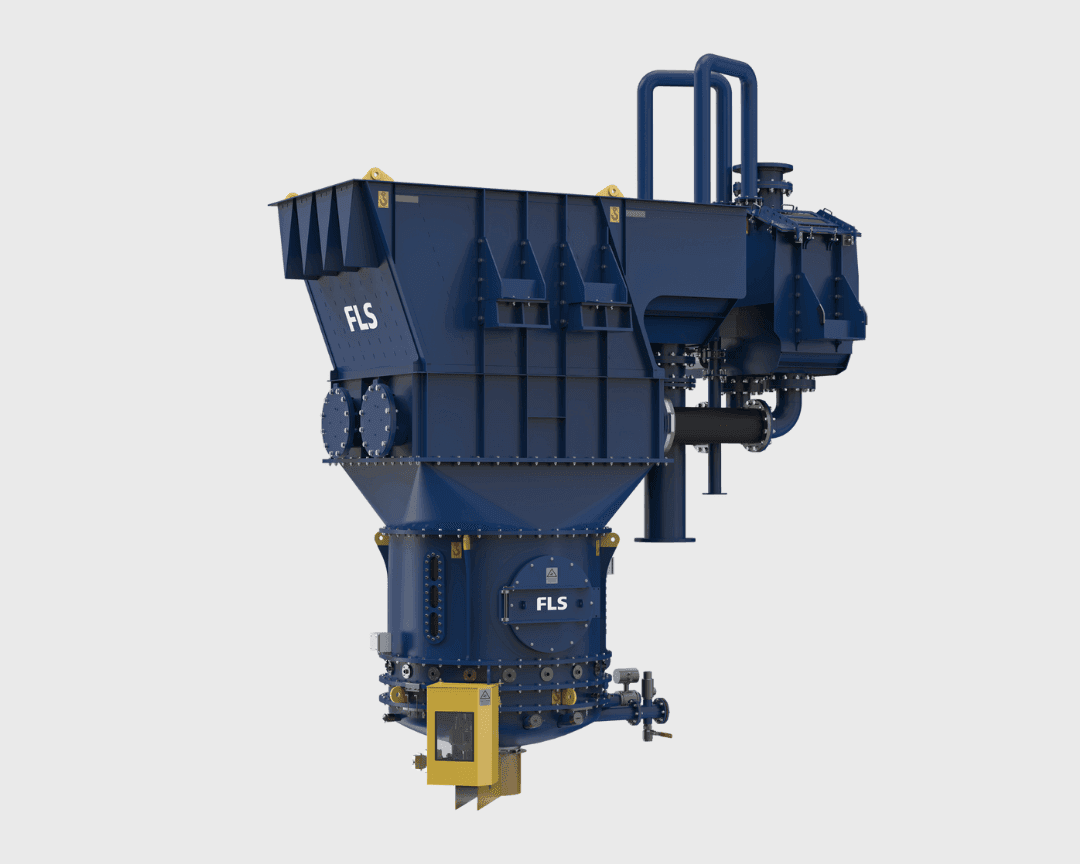

As a Copper Mark partner, FLS endorses developing and disseminating responsible production practices in the copper industry. Our MissionZero Mine initiative, in particular, aims to address these challenges with full-flowsheet solutions that dramatically cut the energy and water intensity of copper ore processing.