Optimise operating costs

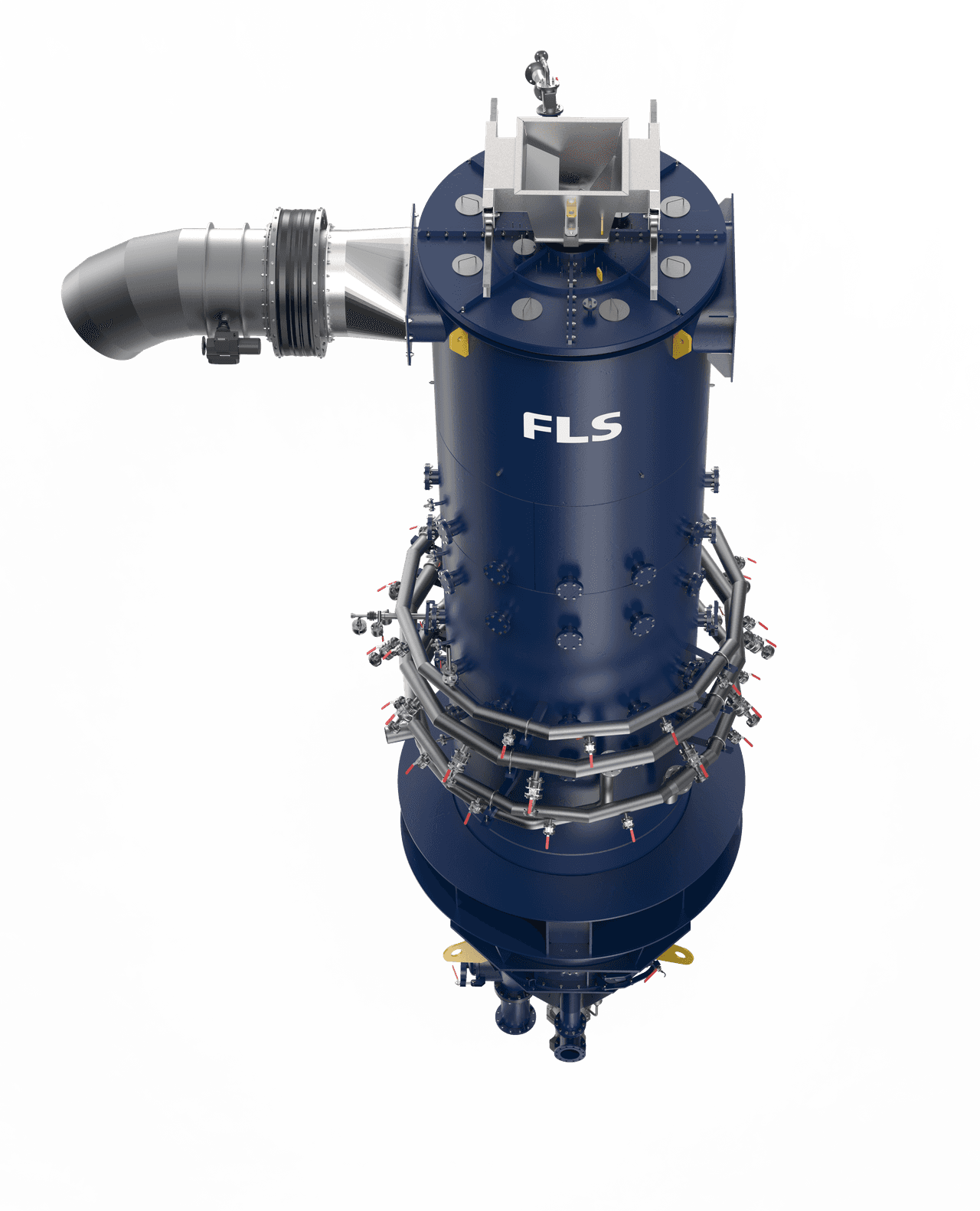

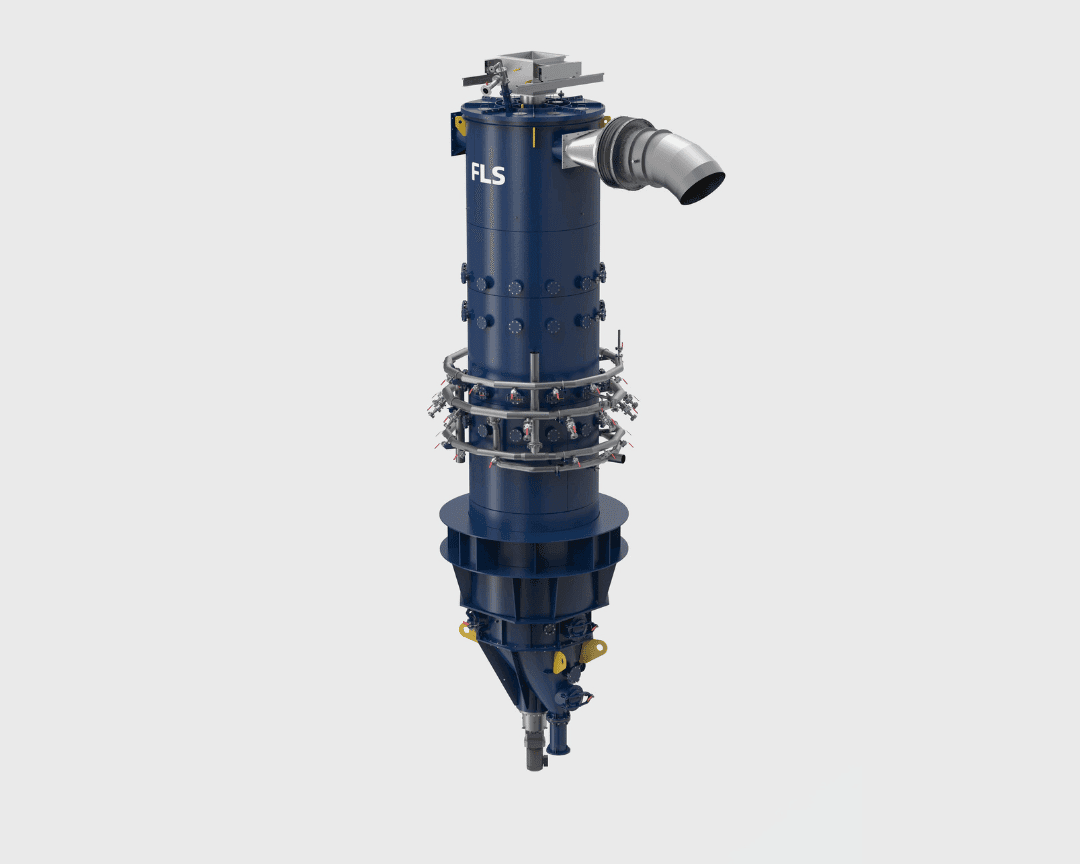

By using the hot air previously used for cooling the product as secondary combustion air, we ensure very little heat is lost from the process. This allows FLS shaft kilns to achieve superior thermal efficiency, reducing overall energy consumption, even as we deliver the highest process temperatures on the market. Our kilns also fire a range of liquid, gaseous, and solid fuels, allowing fuel supply and costs to be optimised according to local fuel availability.