Optimised design enables higher throughput, increased profits

Our optimised, highly durable, lower weight mill liners allow for increased grinding capacity so you can process more tonnes of material.

Our optimised, highly durable, lower weight mill liners allow for increased grinding capacity so you can process more tonnes of material.

With ARMOUR Mill Liners you will spend less time inspecting your mill and more time putting it to use. Our mill liners enable your machinery to run for longer. Less down time means higher profitability. What’s more, if you choose composite mill liners you will benefit from an average 50% fewer parts, leading to faster reline speed and reduced installation time.

Our mill liners are safe and have fewer parts and are therefore quicker to install, significantly reducing downtime. That means workers installing the liners or lifters spend less time in a potentially hazardous situation. Plus, our composite mill liners are on average 50% lighter, offering further benefits to workers’ safety.

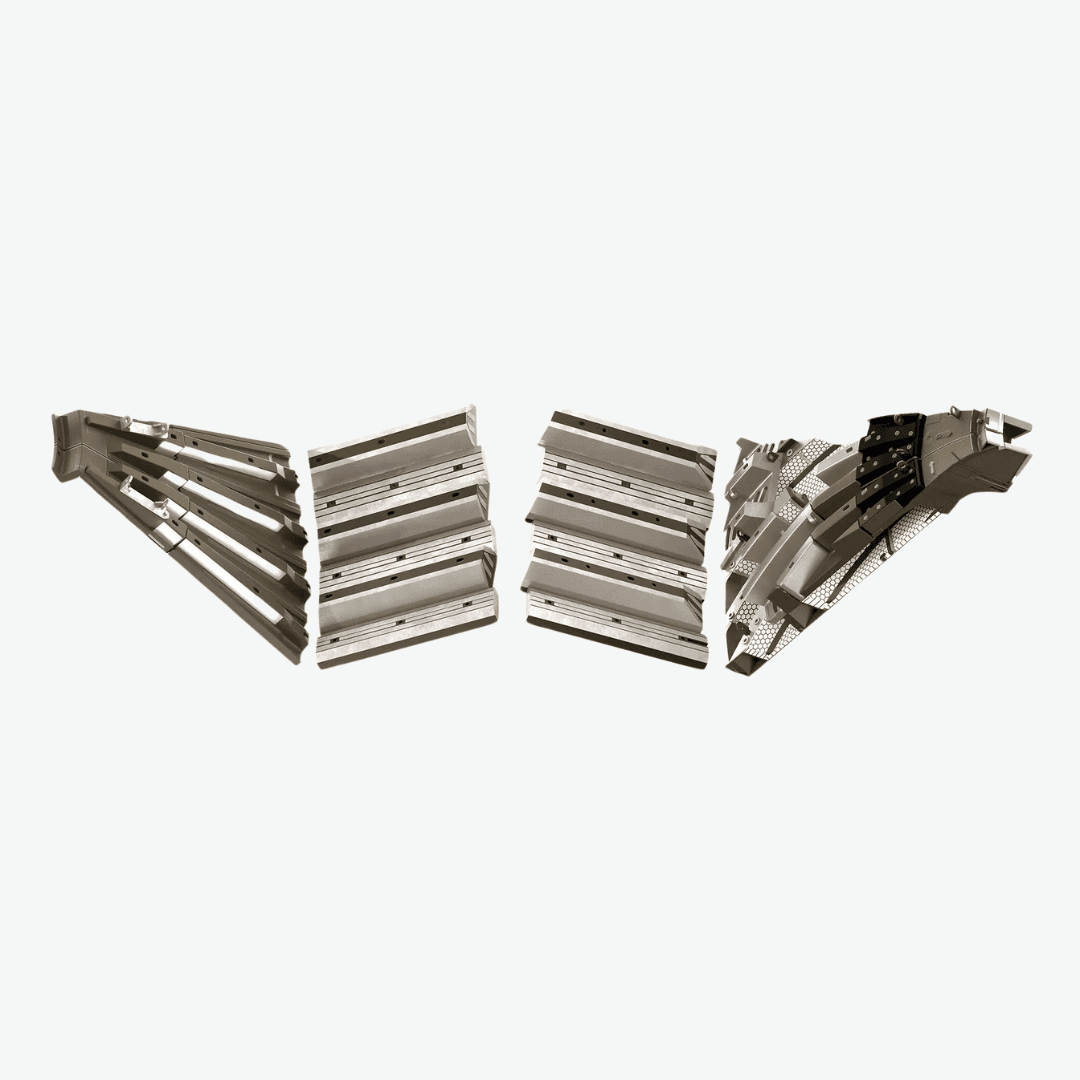

Each grinding mill is unique, so why treat the mill linings differently? We work with you to engineer a mill lining that meets your operational requirements and goals. Choose from three material options:

In mining, there is no one-size-fits-all solution, so every ARMOUR mill liner solution is optimised to your unique equipment needs. Using state-of-the-art simulation technology and industry leading expertise, we precision engineer your mill lining solution to enable you to get more out of your grinding operation.

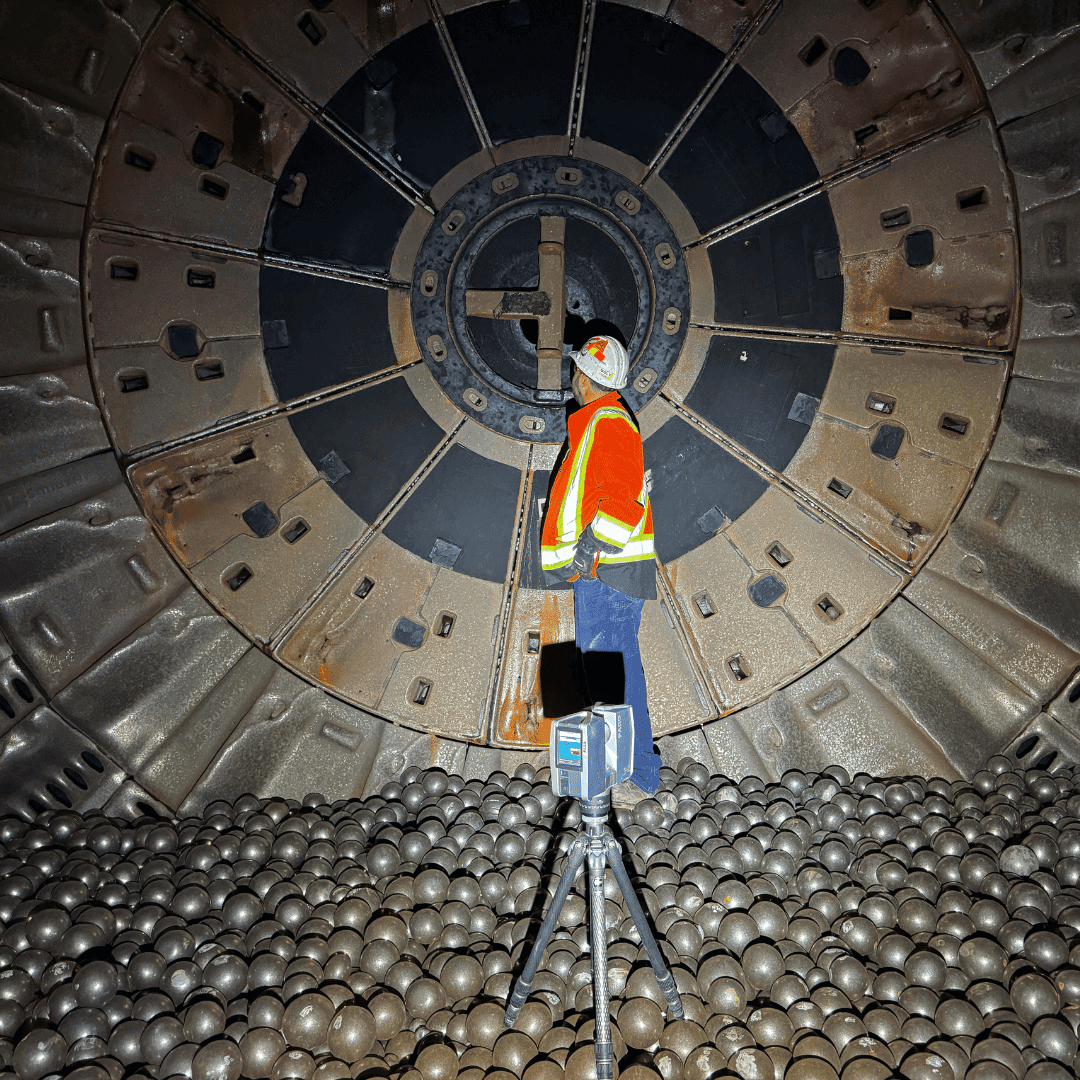

When you invest in ARMOUR™ mill liners, you get more than just a premier product; you get process know-how and expertise earned from working with mining sites around the globe. Our technical experts are available for inventory control services and installation as well as comprehensive maintenance planning and follow-up. Working together, we can help you prevent failure and prepare for maintenance outages using specialist tools and services such as our powerful 3D scans, wear measurements and maintenance forecasts.