Up to 15% energy savings with HPGR Pro

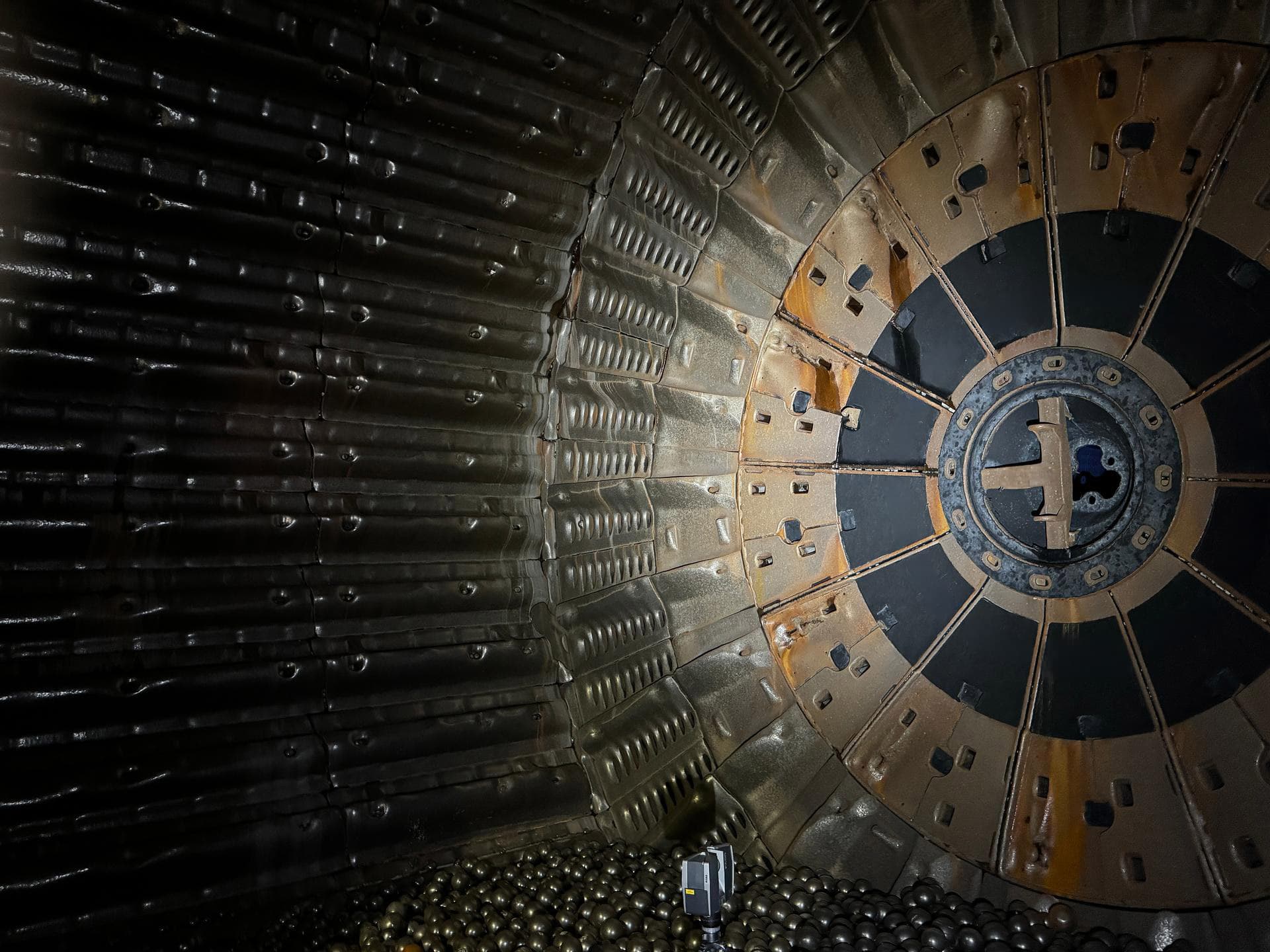

Our HPGR upgrade – HPGR Pro – is a triple threat to grinding mill challenges. Delivering up to 20% more throughput, 15% less energy and up to 30% longer roller life, this upgrade benefits copper, gold, iron ore, and kimberlite operations struggling with limitations in their existing equipment. The upgrade is relatively simple – we've redesigned the HPGR rollers with a flanged design with skew limiter – but the impact is huge.

Learn more