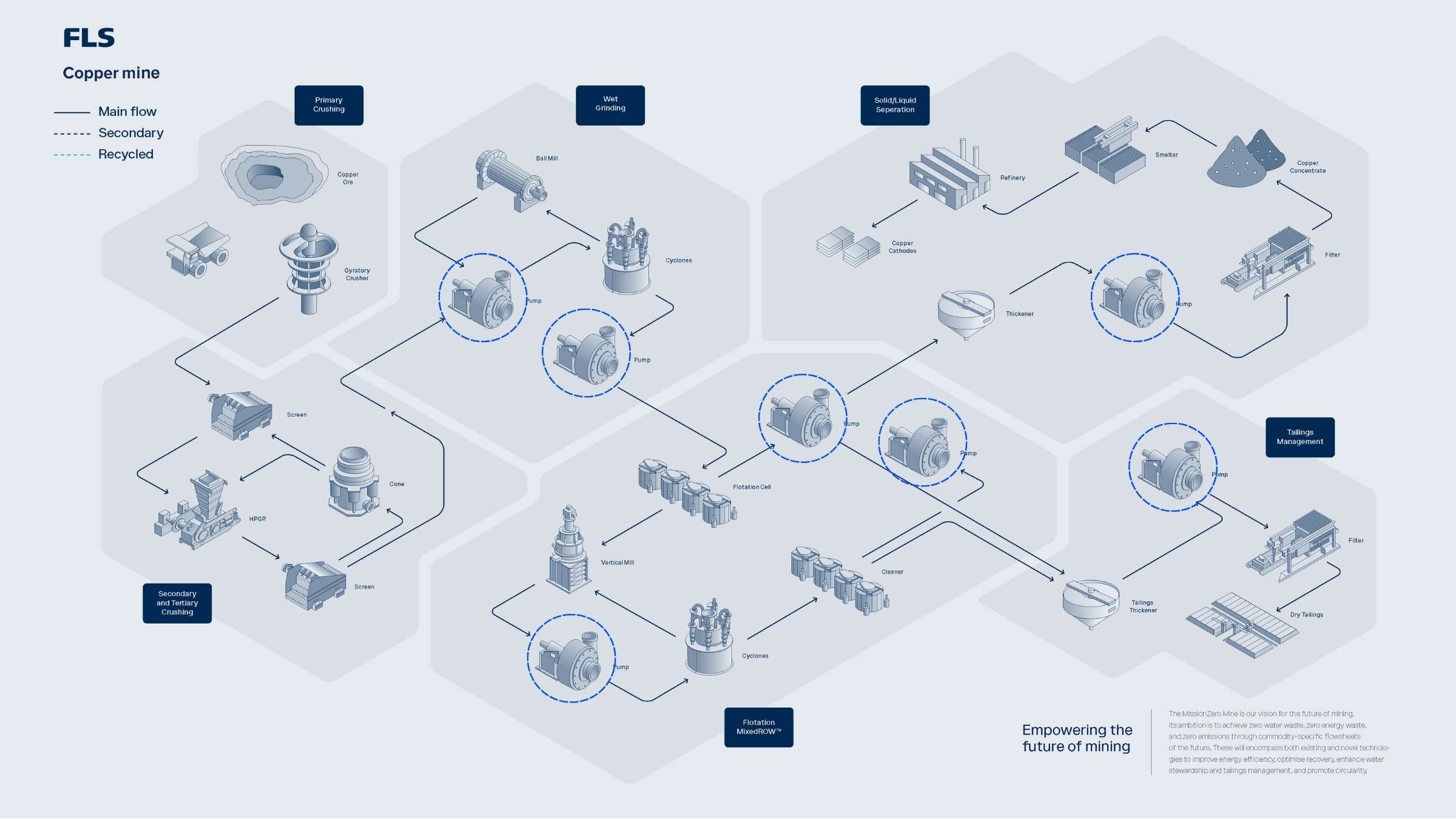

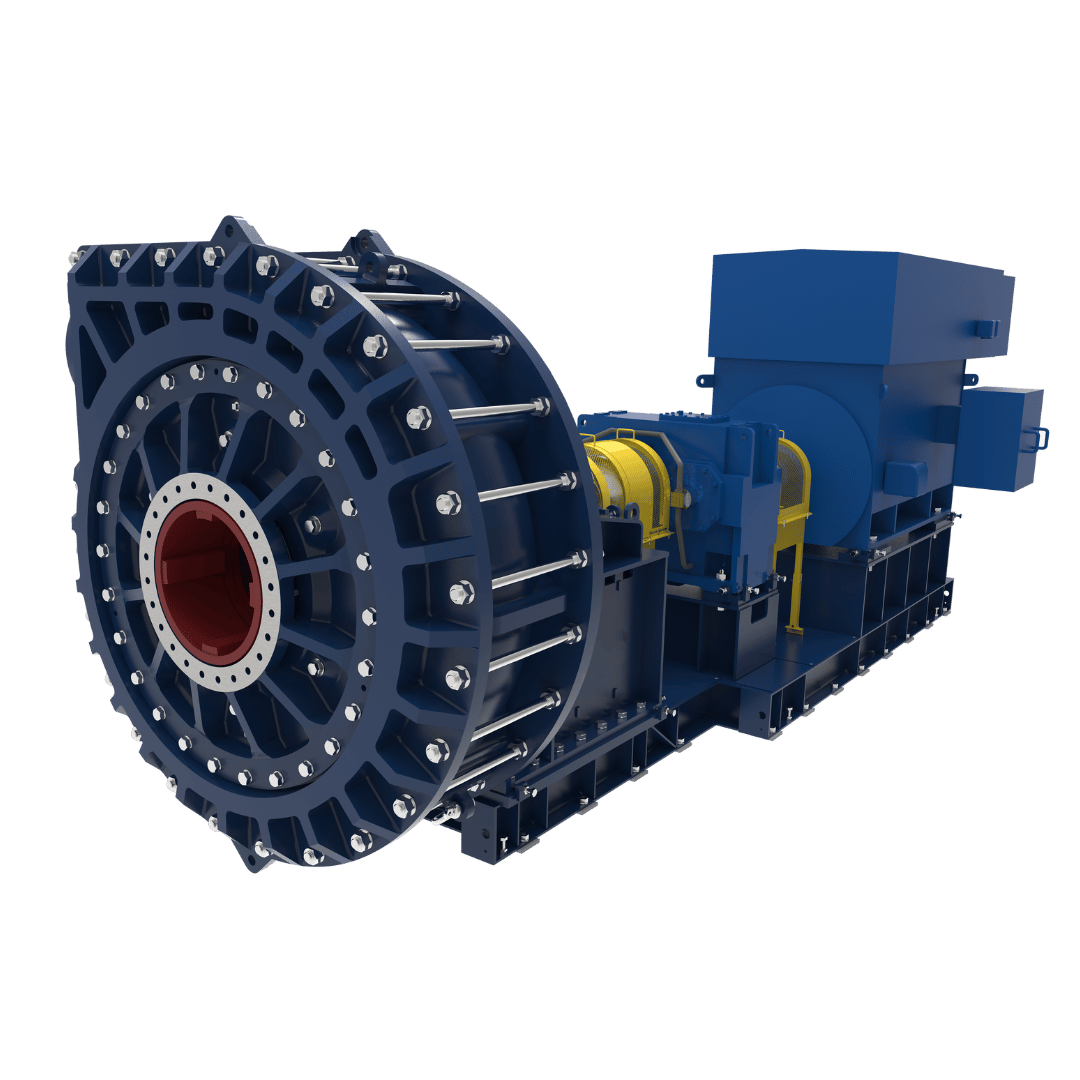

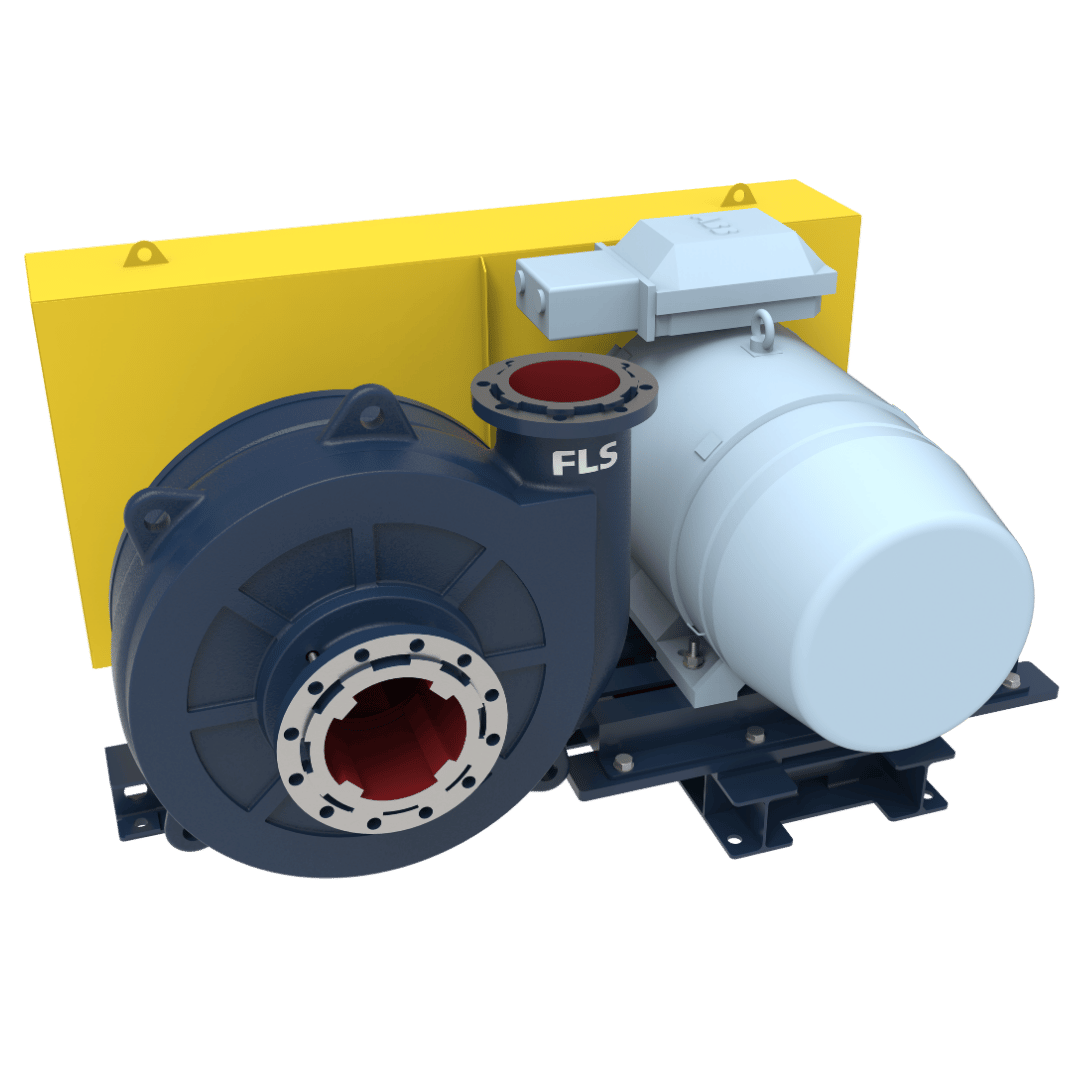

It is the slurry pumps’ job to keep the slurry flowing, but this essential task comes at a cost. Energy-related emissions dominate a pump’s lifecycle carbon footprint and contribute substantially to the overall costs and carbon emissions of mineral processing operations.

The growing demand for minerals expected in the years ahead adds to the challenge, exacerbated by declining ore grades, which means more ore must be processed to maintain, let alone increase, production. Both factors are likely to contribute to a rise in the volume of slurry that mineral processing plants must handle. This makes improving pumping efficiency one of the primary missions in the quest to reduce mining’s carbon emissions.

The pump energy efficiency challenge

Due to the abrasive nature of mining slurries, slurry pumps in mineral processing applications are exposed to significant wear. This wear degrades pumping efficiency over time, as well as shortening the pump’s service life. Two particularly unwelcome phenomena play a role here: recirculation and in-pump grinding. To understand these processes, a short digression into the workings of a slurry pump is needed.

Fluids naturally flow from areas of high pressure to areas of low pressure. Centrifugal slurry pumps use this principle to move slurry through the pump and beyond. The pump’s impeller throws fluid to the outer walls of the casing, creating a low-pressure zone at the eye, drawing new, higher-pressure fluid from the suction. Meanwhile, the higher-pressure fluid at the walls ideally flows out to the discharge pipe. However, when there is a gap between the impeller and suction-side liner, this fluid may flow back toward the eye. This is known as suction side recirculation.

Recirculation substantially degrades pump efficiency. It also exacerbates the risk of in-pump grinding of solids in the slurry, which can cause severe localised wear and erosion, further degrading performance. Thus, developing a solution that effectively and safely mitigates recirculation and ensures grinding occurs in the mill, not the pump, was imperative for improving pump sustainability.

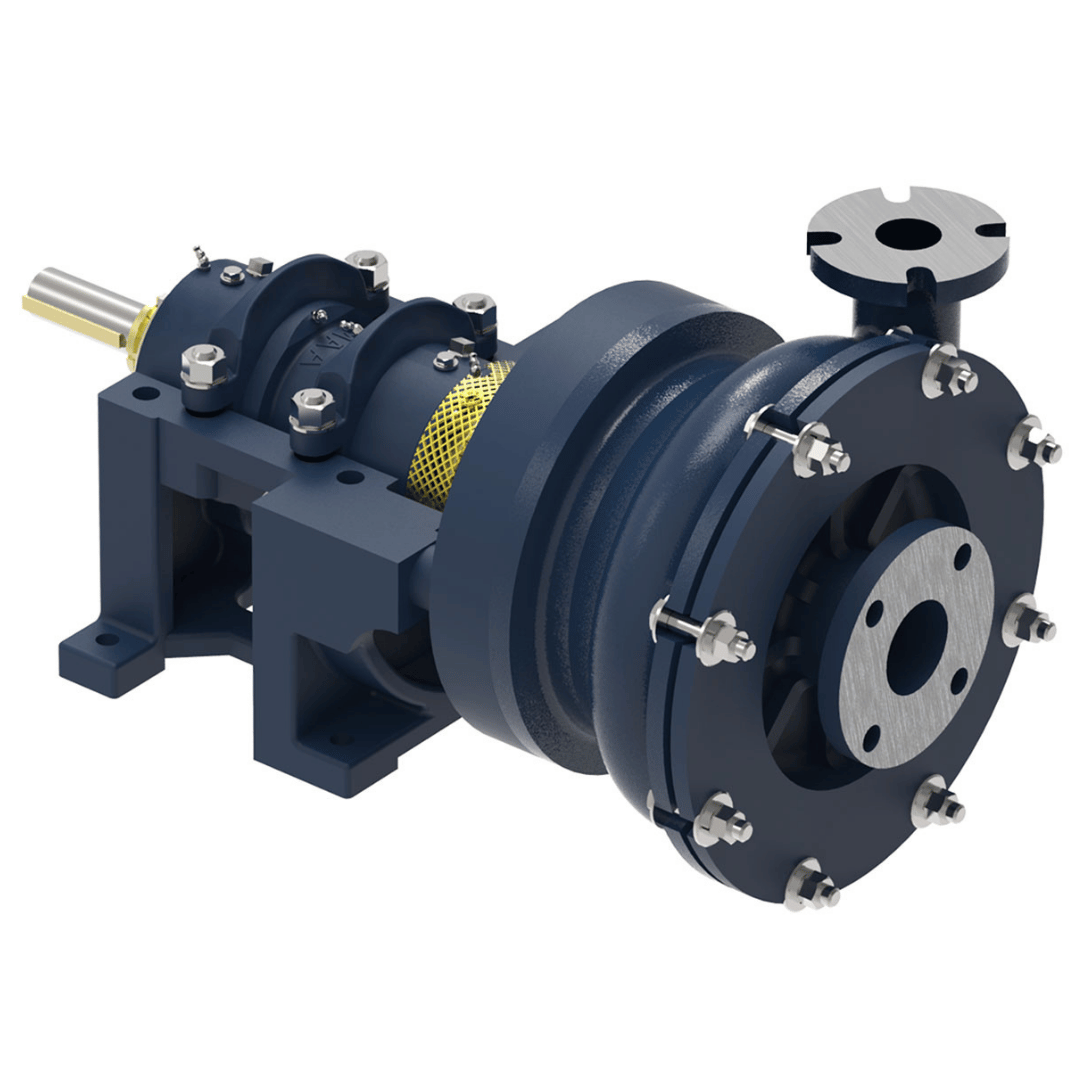

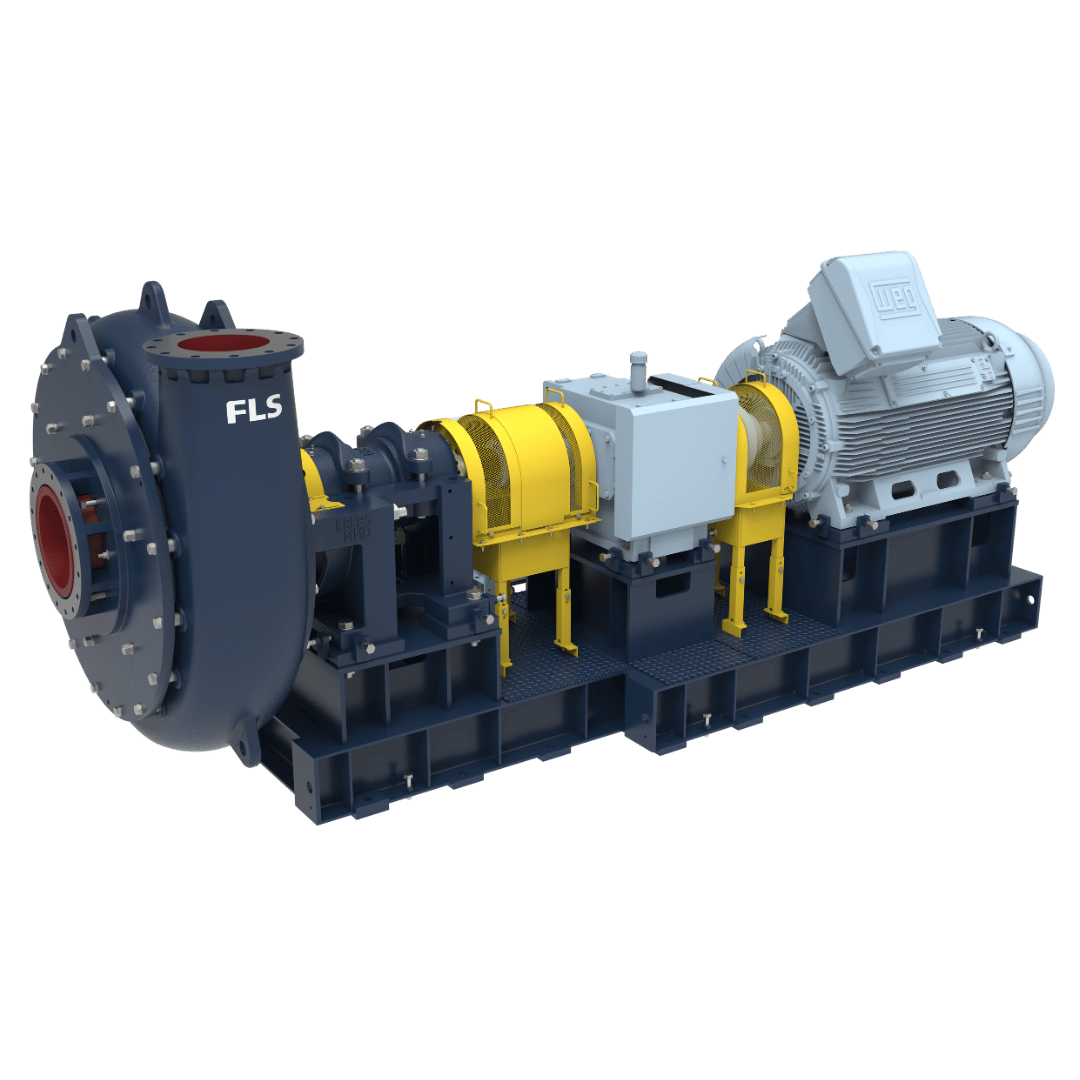

The solution: a patented wear ring

KREBS’ externally adjustable wear ring technology is just that solution, enabling the suction-side clearance to be controlled while the pump is operating. This controls recirculation and eliminates in-pump grinding, helping to maintain the pump’s design performance over its life without increasing pump speed. In contrast, pumps without a wear ring must increase their operating speed to maintain performance, which causes even faster wear and exacerbates the operational challenges described above.

The sustainability benefits of the wear ring are significant, reducing pump energy consumption (and thus its associated emissions) by 5% to 10% in slurry applications. This results in a smaller global warming potential per cubic meter of slurry pumps, ranging from 4.8% to 9.7% lower compared to the best-performing alternative. It also significantly reduces operating costs.