Screens in dewatering and process water applications

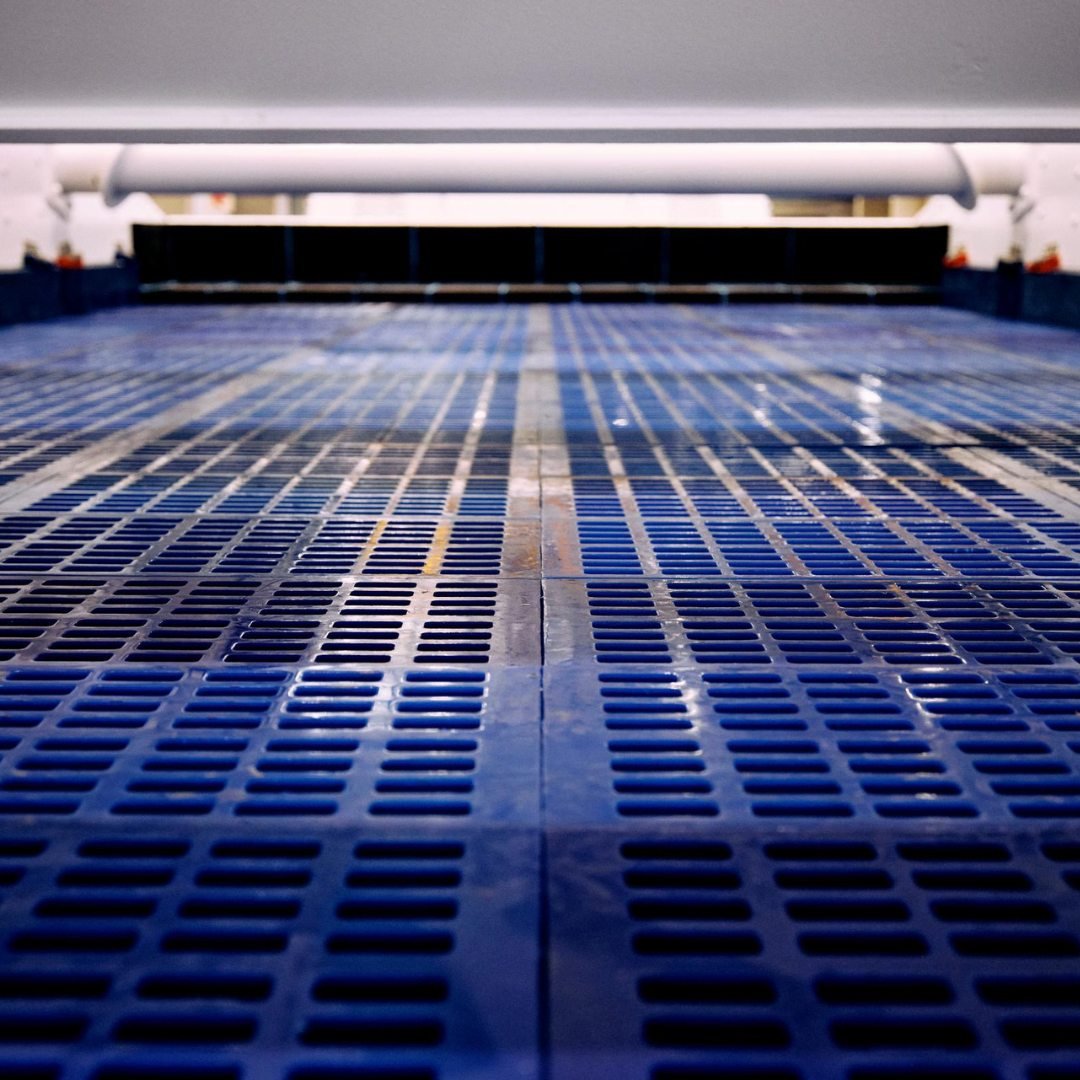

Effective dewatering screening removes water at the source - immediately after classification, beneficiation, or separation - reducing the load on thickeners and filters while improving circuit water balance. When dewatering underperforms due to blinding, incorrect motion, or inadequate media selection, product moisture increases, handling becomes difficult, downstream equipment works harder than necessary, and water recovery suffers.

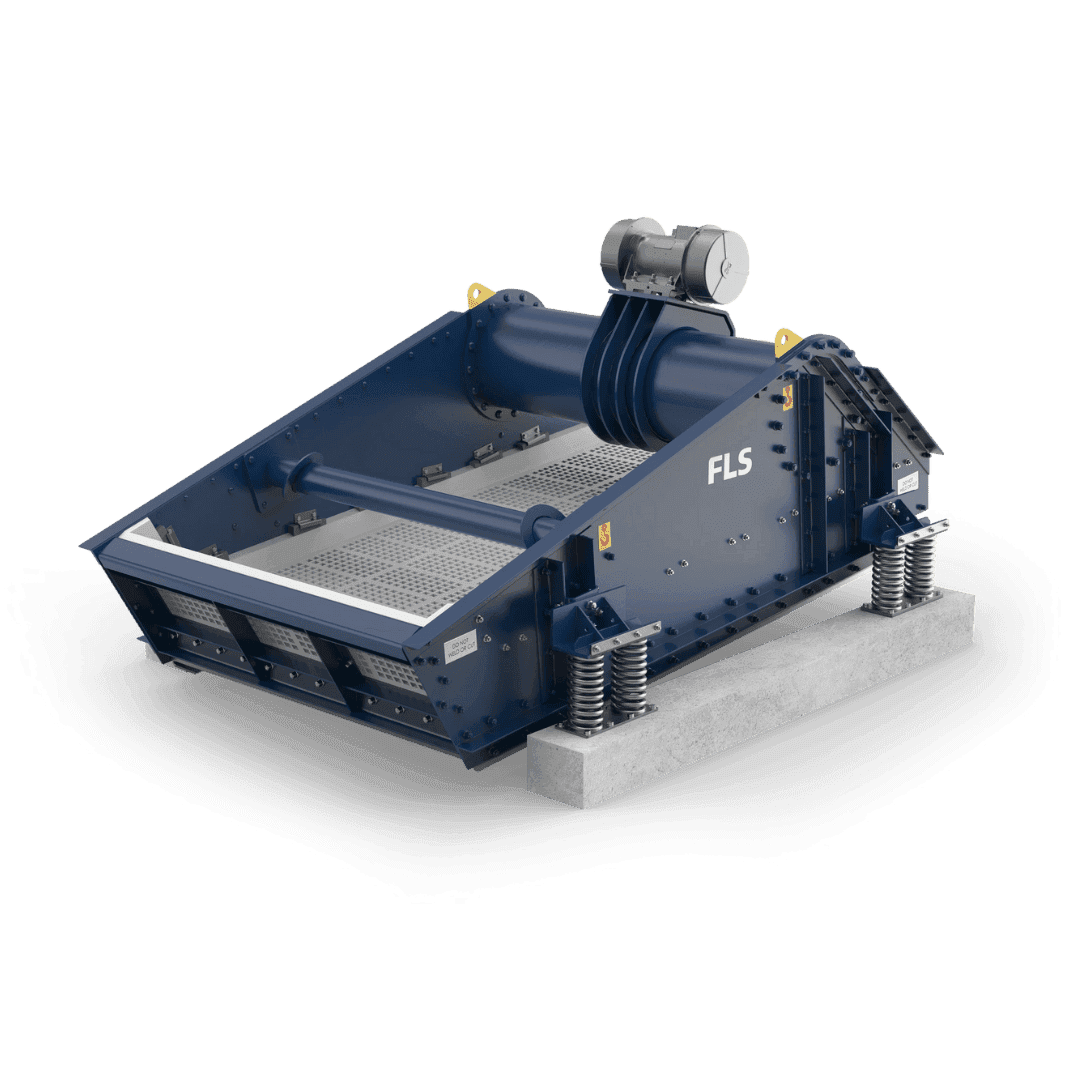

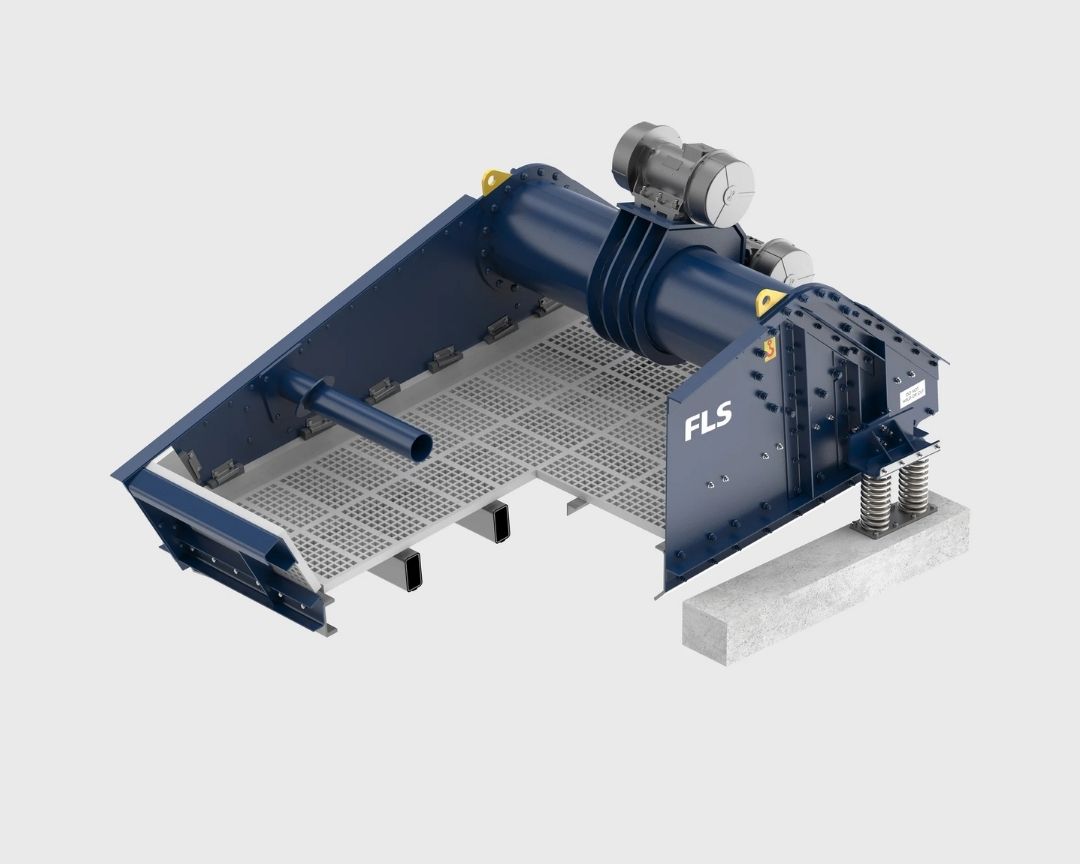

FLS screening solutions address these challenges across multiple applications. VSW Series dewatering screens serve as the primary moisture-control solution for tailings or middling streams that require dewatering to ease the load on downstream thickeners and filters while reducing moisture-related handling issues. When placed after classification, flotation, spirals, magnetic separation, or other beneficiation stages, VSW Series units produce a cleaner, more conveyable product, while maximising the water returned to the process.