Screens in grinding and classification circuits

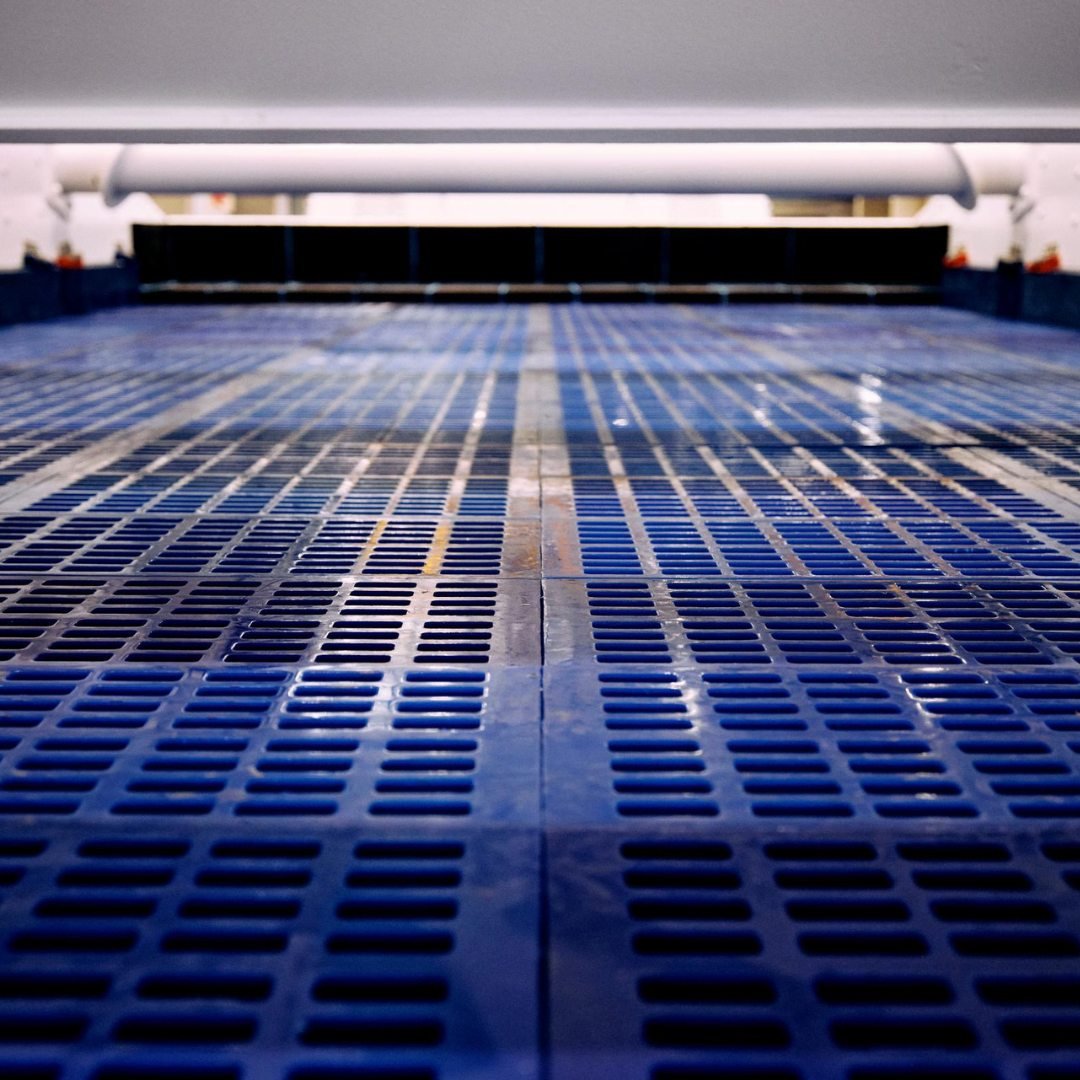

By keeping only the material that needs further grinding in the mill while allowing on-spec material to move forward to separation, screening plays an essential role in reducing energy waste and maintaining a stable cyclone feed. When screening underperforms through blinding, incorrect motion, or equipment failure, however, mills over-grind, recirculating loads climb, and energy consumption increases while throughput suffers.

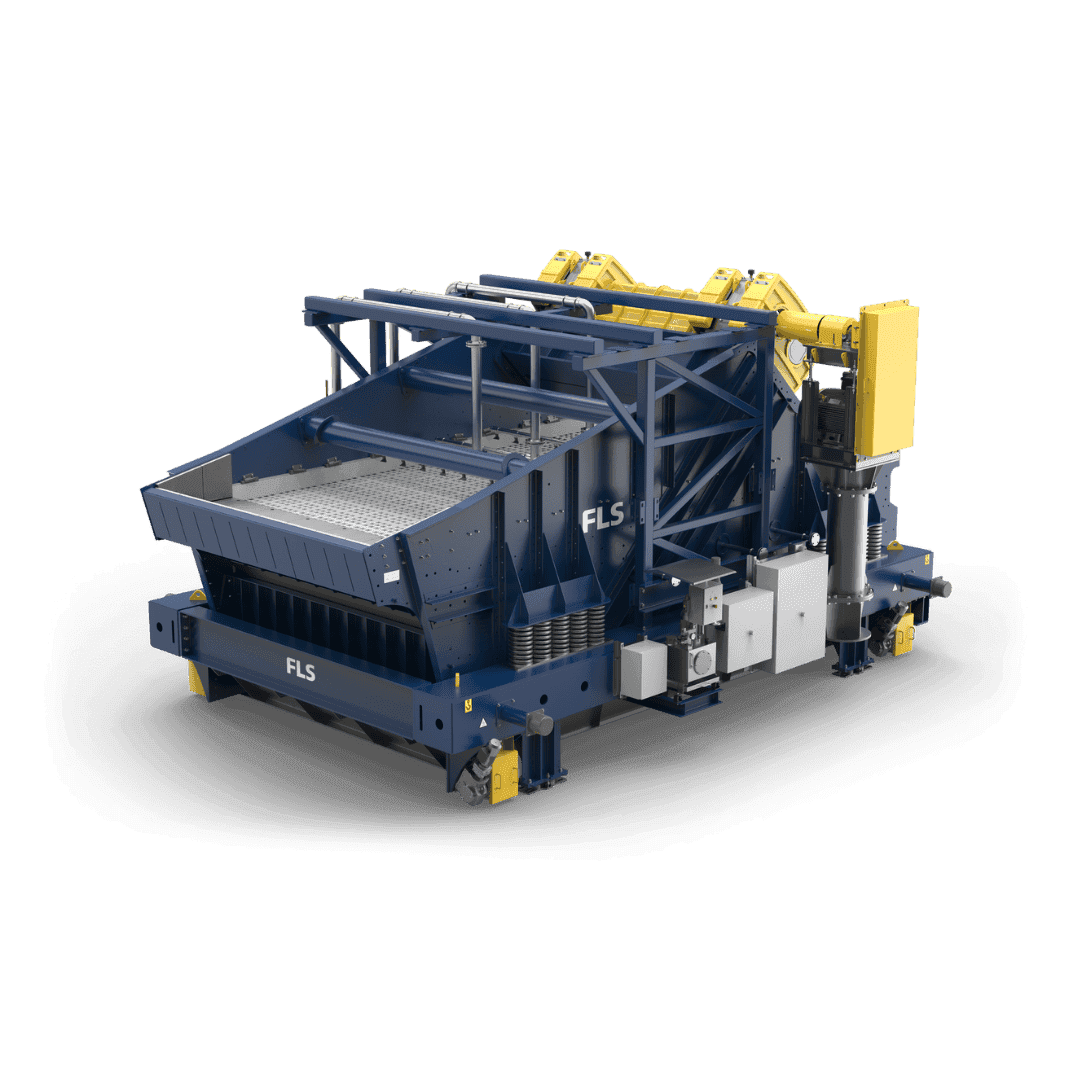

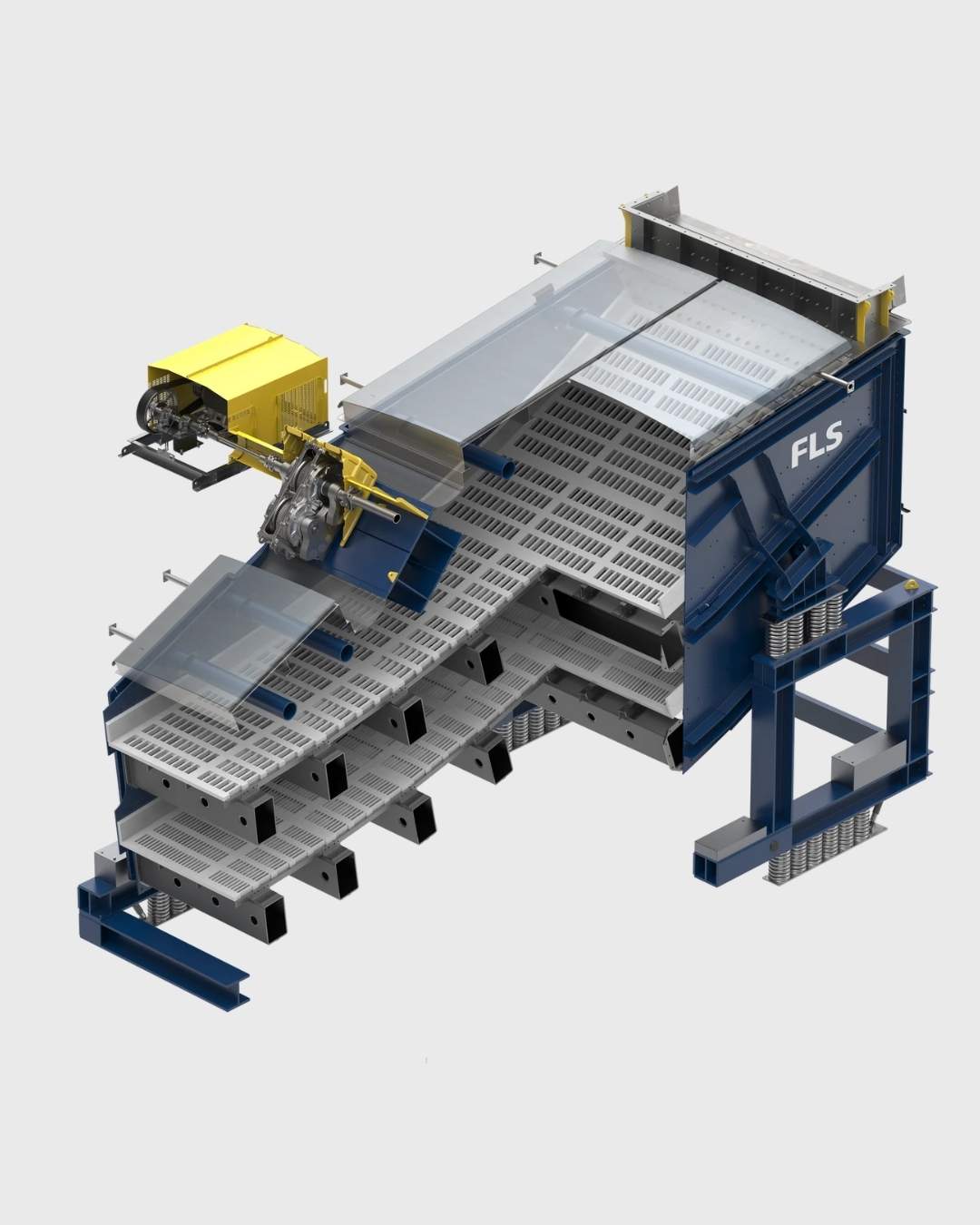

FLS screening solutions address these challenges across multiple circuit positions. At SAG mill discharge, BRX Series screens - typically in a horizontal configuration -remove correctly sized material early, reducing recirculating load and lowering specific energy consumption at the mill. Meanwhile, for wet and dry classification duties, the BRX Series screens provide precise particle-size separation for downstream flotation, gravity separation, or product specifications.