Screens in crushing circuits

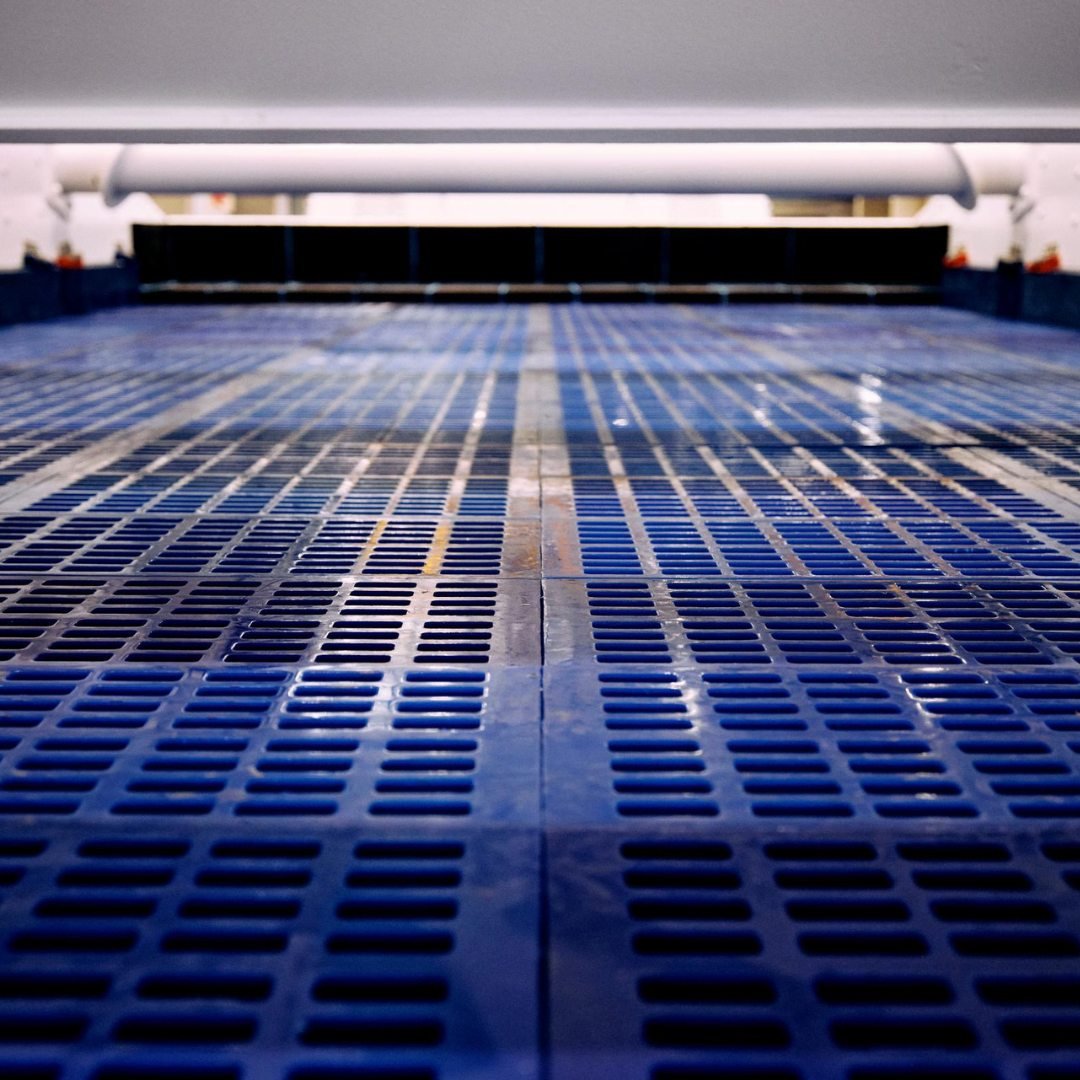

Screens play a critical role in protecting crusher capacity. Effective screening removes non-crushable material before it reaches the crusher, directs correctly sized feed into the crushing chamber, and ensures downstream processes receive consistent, on-spec material. When screening underperforms—whether due to blinding, incorrect cut sizes, or unplanned downtime—the entire circuit suffers, with crushers operating inefficiently, higher recirculating loads, and lower throughput.

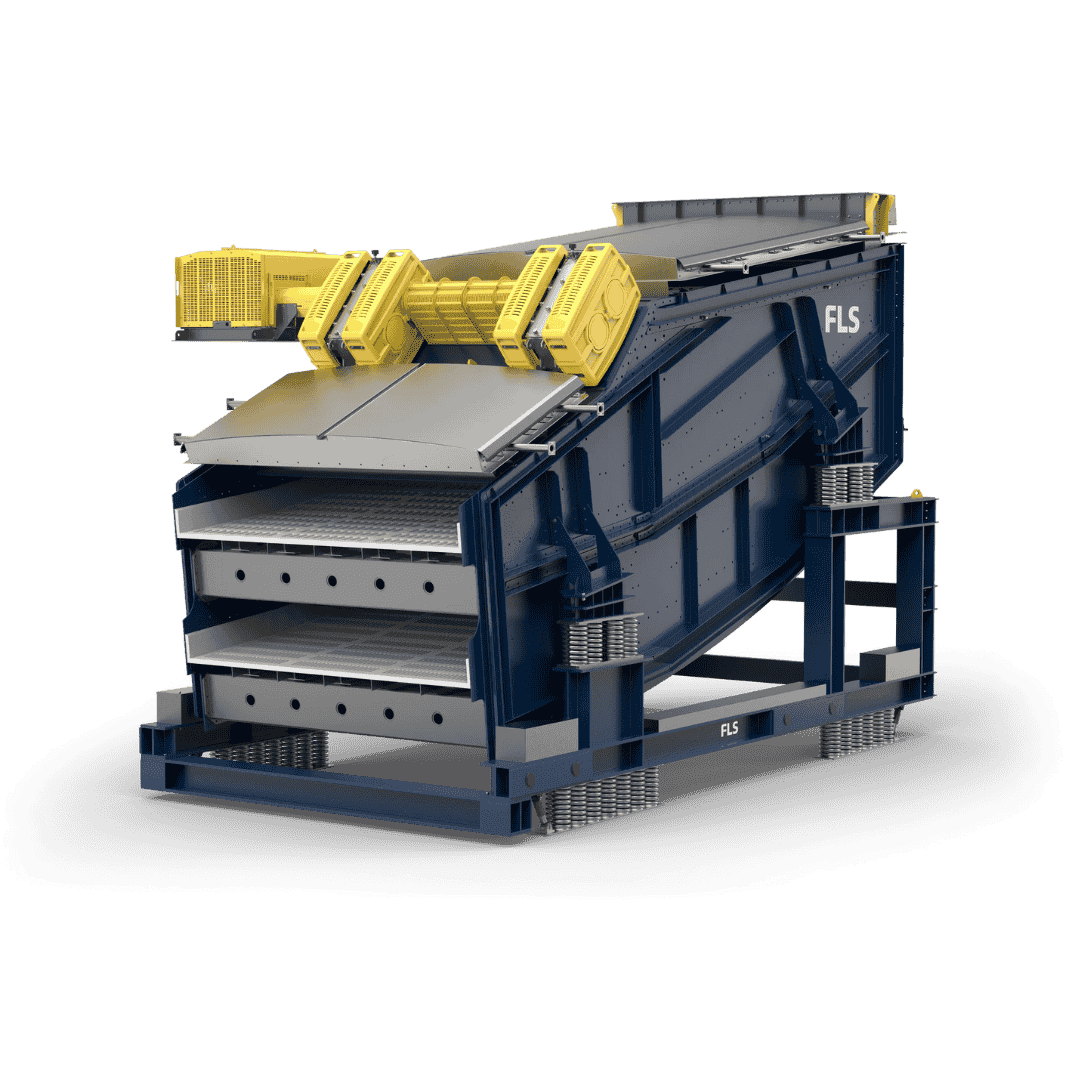

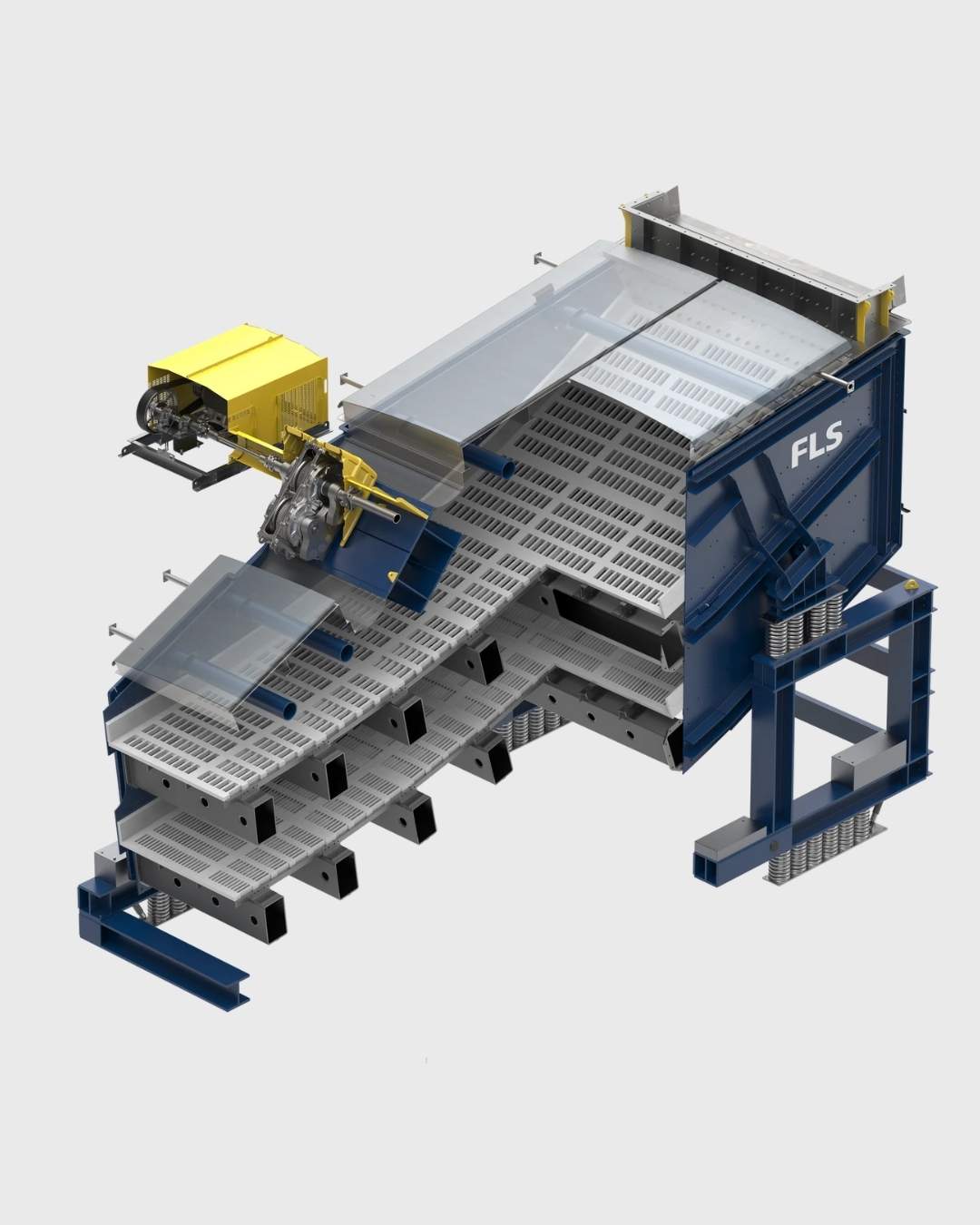

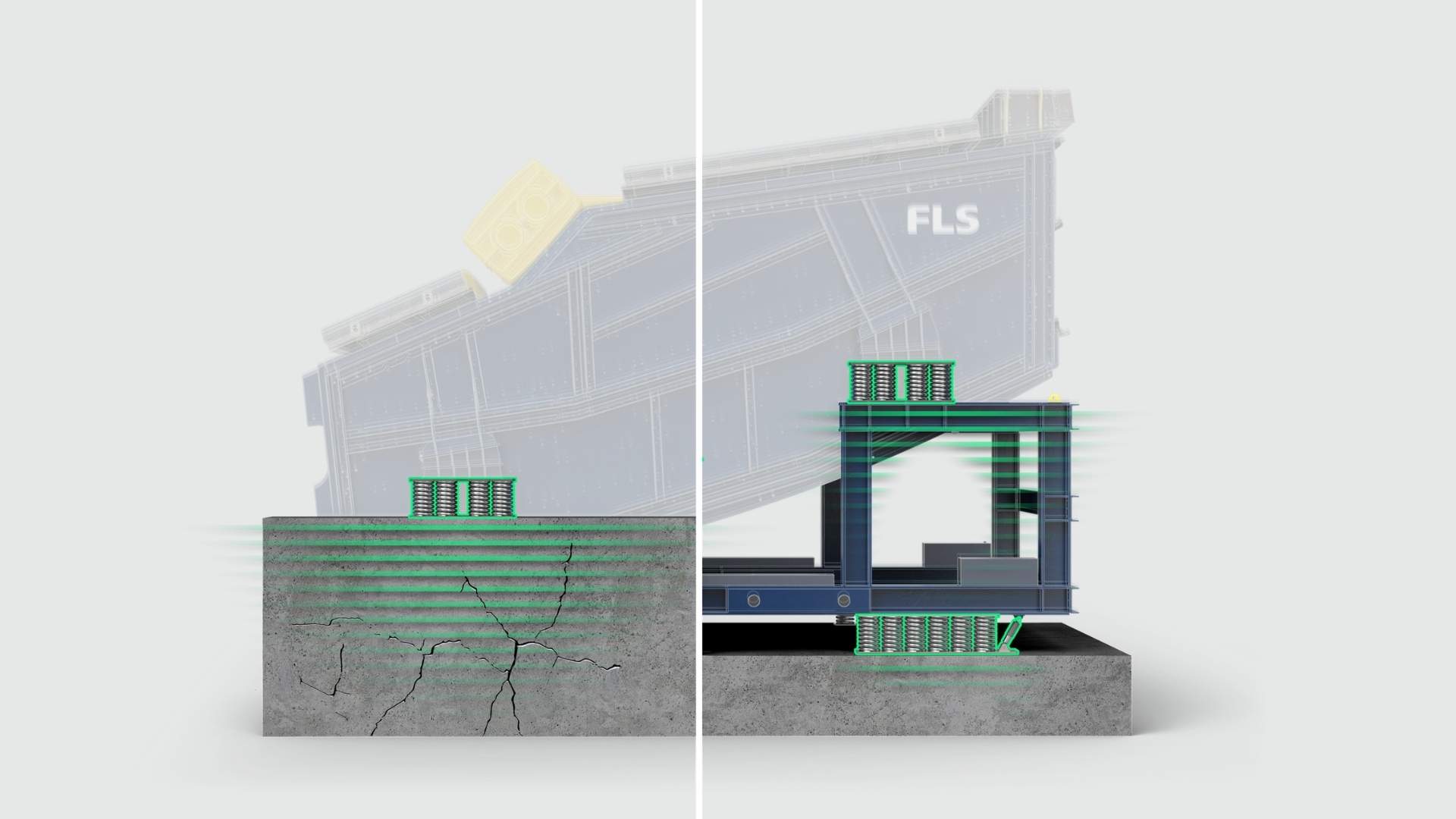

FLS screening solutions for crushing circuits are designed to address these challenges head-on. By selecting the right screen geometry, motion profile, and media configuration for each application, we help mining operations stabilise feed rates, reduce unnecessary recirculation, and keep crushers working to targets. Our BRX Series screens deliver the capacity and cut-point control required across primary, secondary, tertiary, and quaternary crushing stages - as well as demanding HPGR discharge applications.