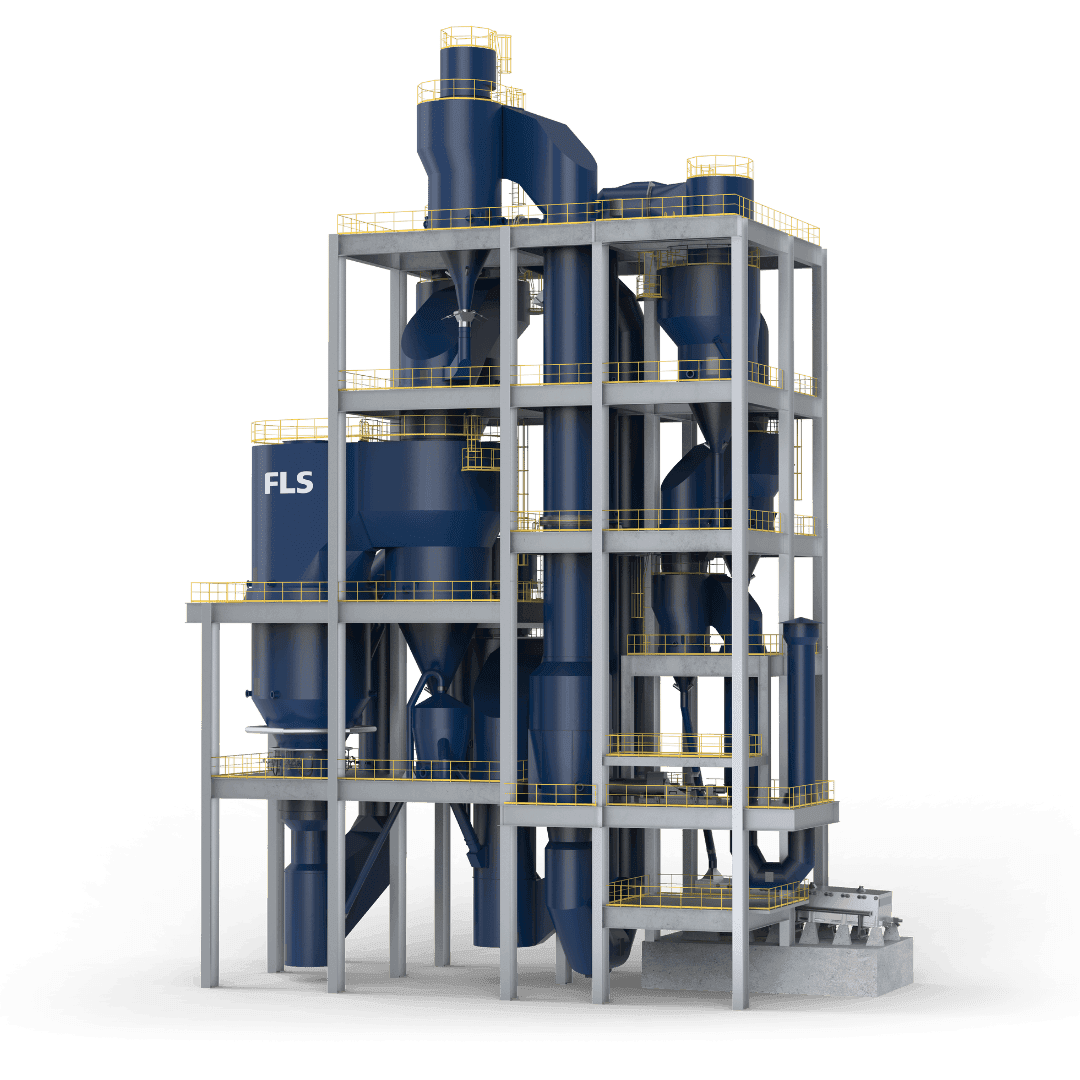

Our gas suspension calciners

Gas suspension calciners are used for the thermal treatment of fine materials, such as potash, phosphate, limestone, magnesite, gypsum, alumina, trona, clays, and talc. This may be an intermediate stage before subsequent smelting or other processing steps, or as an end-of-flowsheet solution to yield a final product. Each GSC is custom engineered to deliver optimum application-specific performance. Capacity potential, fuel and power consumption thus vary significantly between installations. For example, we have designed units with processing capacities as low as 1tph and as high as 800tph. Whatever the specifications, however, all GSCs are delivered as complete systems that make your job easier and more productive.

We have experience supplying gas suspension calciners in a wide range of sizes from very large installations (up to 10m dia.) to smaller-scale systems (1m dia.). When internal access is restricted such that maintenance cannot take place in situ, integral platforms support the safe dismantling and removal of components via mobile cranes for maintenance. We also supply limited-diameter components with pre-fitted refractory linings to ease onsite installation.