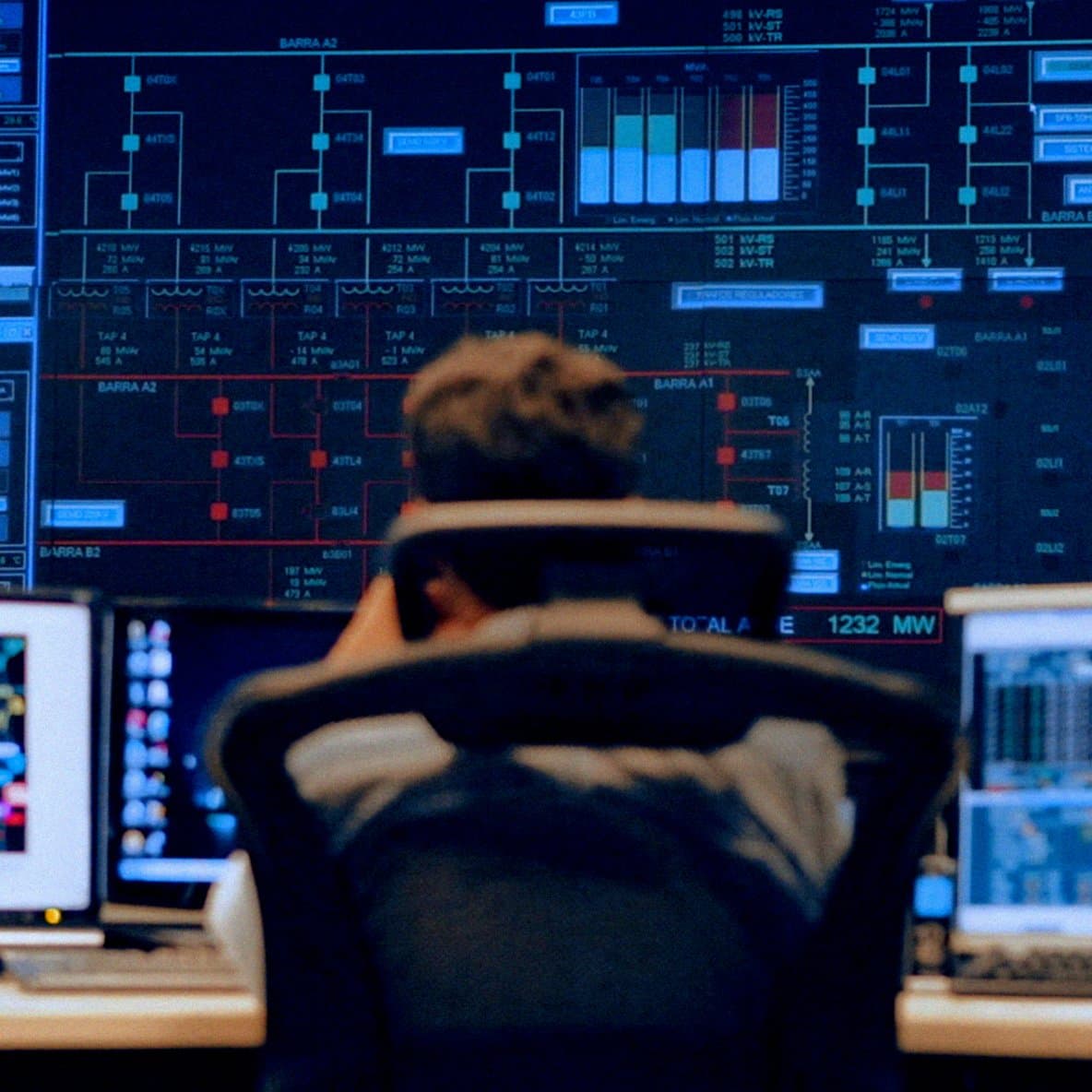

Cutting edge technology helps you increase productivity

Our Asset Optimisation services employ advanced, digitally-enabled solutions to help you increase productivity. For example, you can achieve a 3 – 6% increase in mill throughput by implementing LoadIQ™ and a 2% increase in mineral recovery in your flotation circuit using PlantVision froth cameras plus advanced process control.