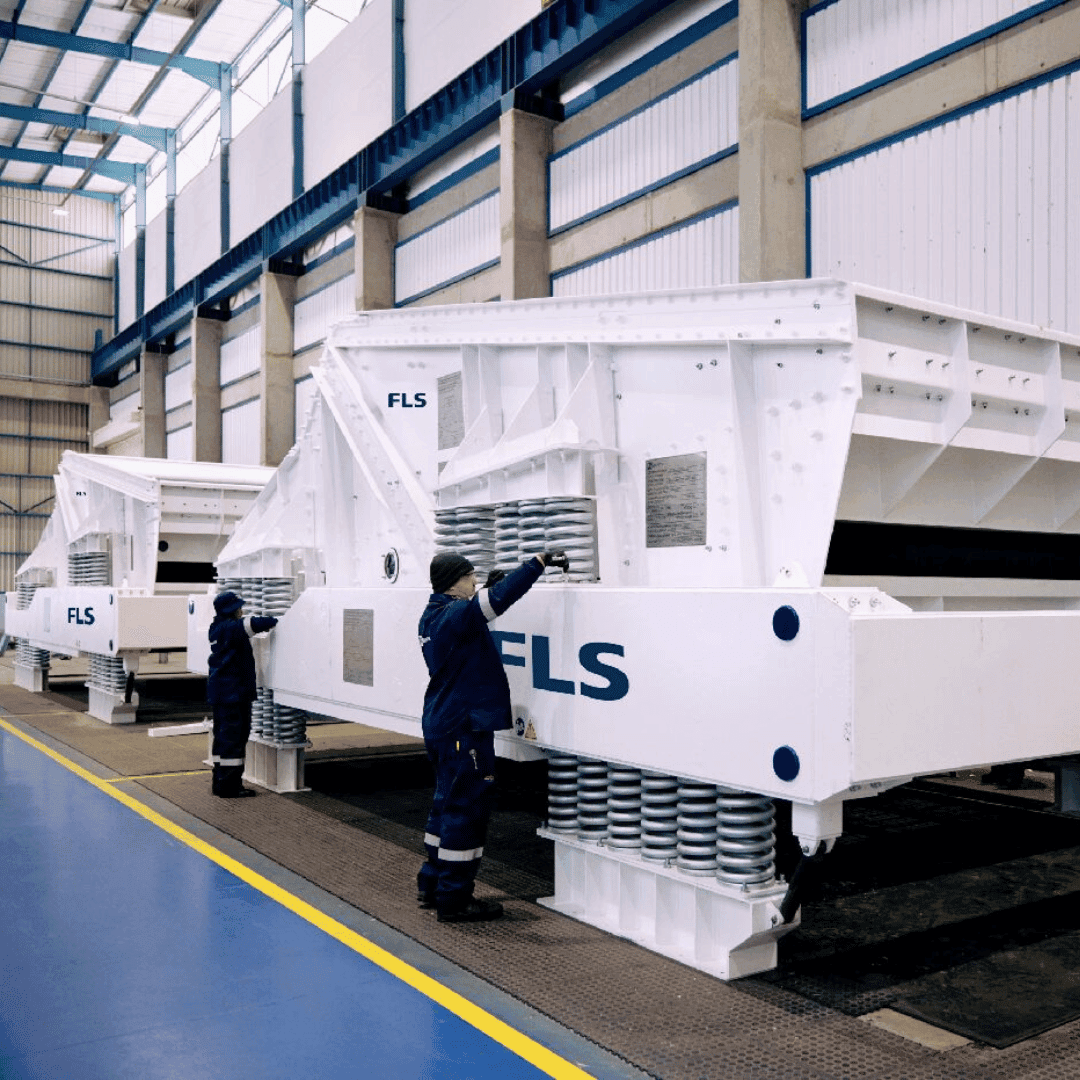

Reduce costs with screen rebuilds

Screens suffer intense wear and tear over an average life of around 5 years. But at the end of this time, you don’t need to scrap your screen – you can rebuild it. Rebuilding restores screen performance and improves screen efficiency without subjecting you to the long lead times and large capital cost of a new screen. Replacing worn components at the appropriate time will bring the whole machine back to as-new condition and depending on the commodity could extend the operating life for an additional 5 years.