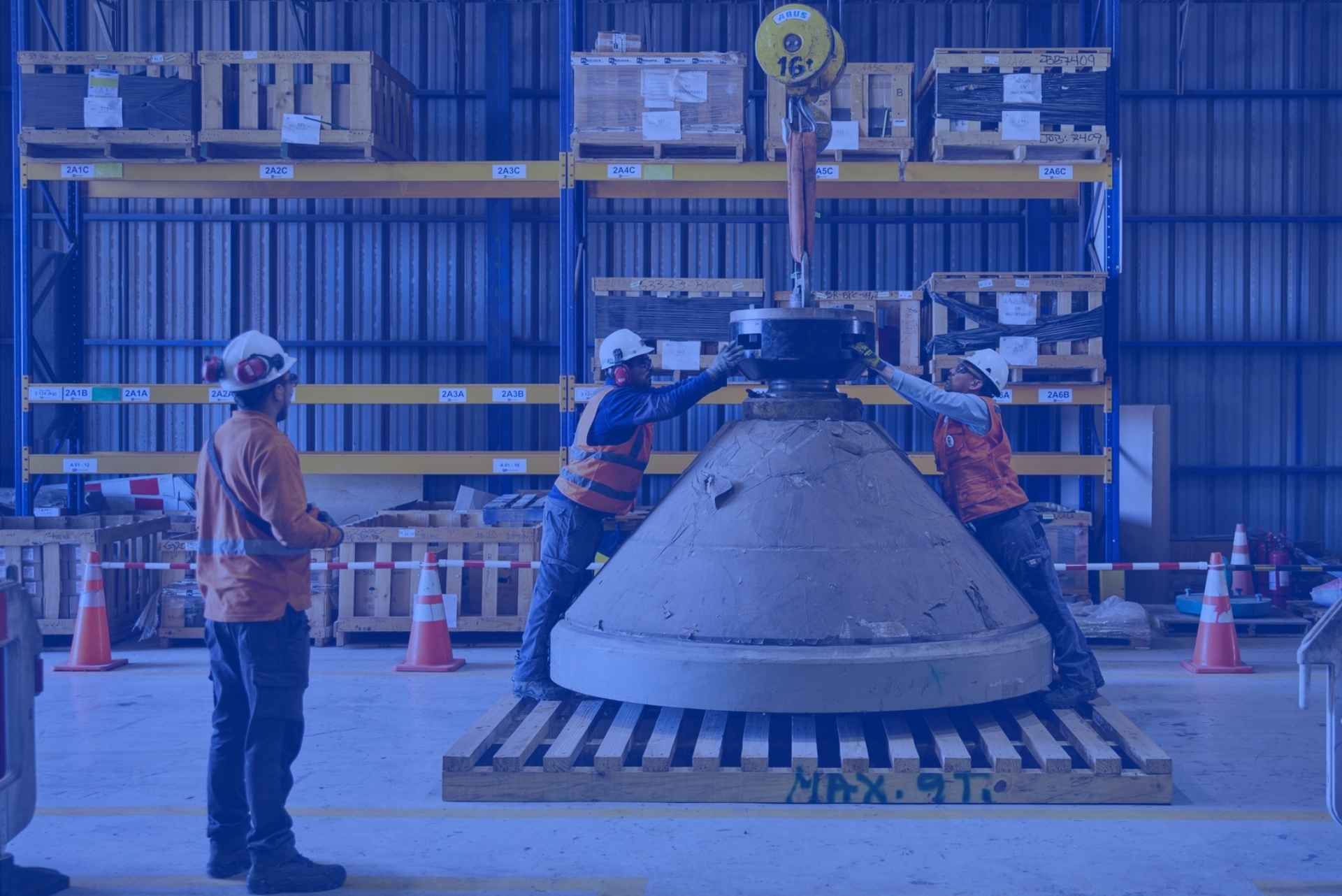

Versatile crushing to application needs

Every crushing project is different. Our range of Raptor cone crushers is configurable to meet your application needs. So, you can operate them with the confidence that the most common challenges are being addressed, delivering excellent results at low cost.

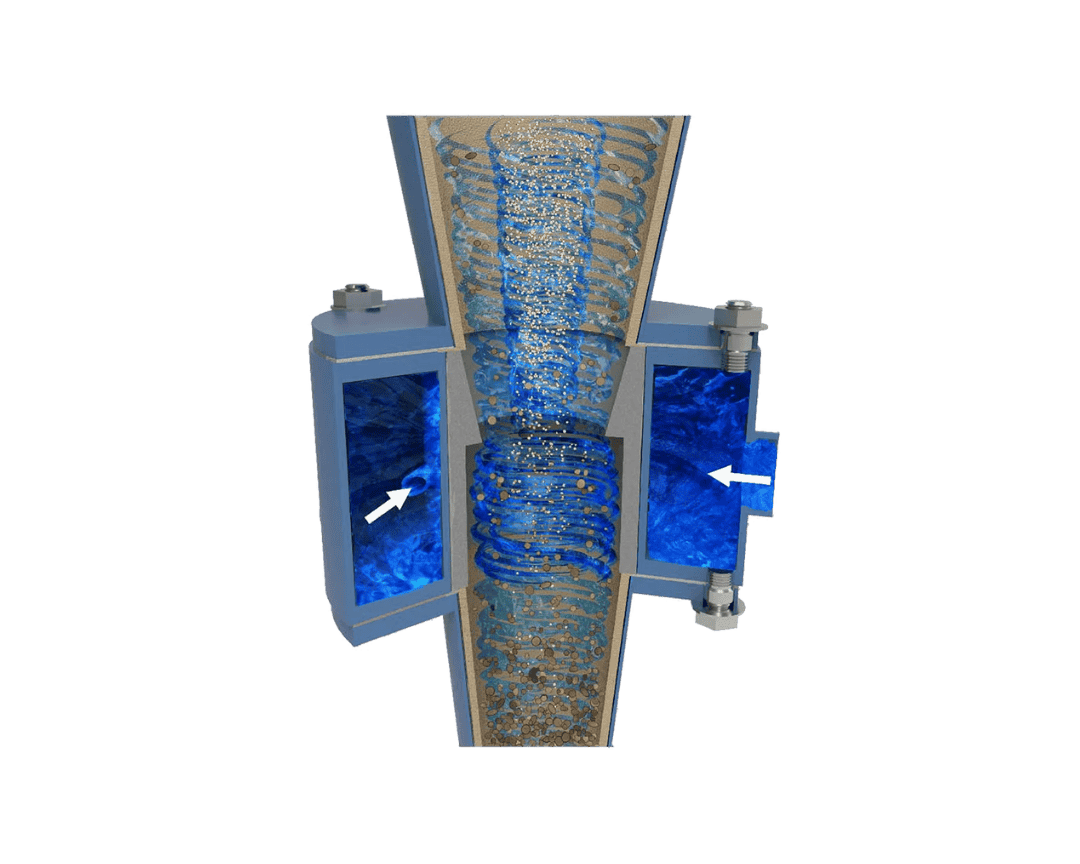

Single-size materials

Quarries face increasing demand for a narrow range of single-size materials. Raptor cone crushers feature a high stroke to produce a better particle shape and reduce the circulation load in a closed circuit. Because of the lower circulation load, they also produce less sand. This means less waste: a vital factor in a business when sustainability is a high priority.

Precise shape

Construction applications, such as highway applications and concrete production, often require precise aggregate shape, stable grading, and a uniform particle-size distribution with a minimal fine fraction. Raptor cone crushers’ products meet or exceed international standards for construction materials. In sand production, these crushers reliably manufacture washed sand that meets concrete standards, including individual rounding and minimum fines.

Waste recycling

Raptor cone crushers effectively process recycled concrete, old asphalt pavements, and masonry into reusable stone for new construction, supporting circular economy objectives while reducing demand for new material extraction.