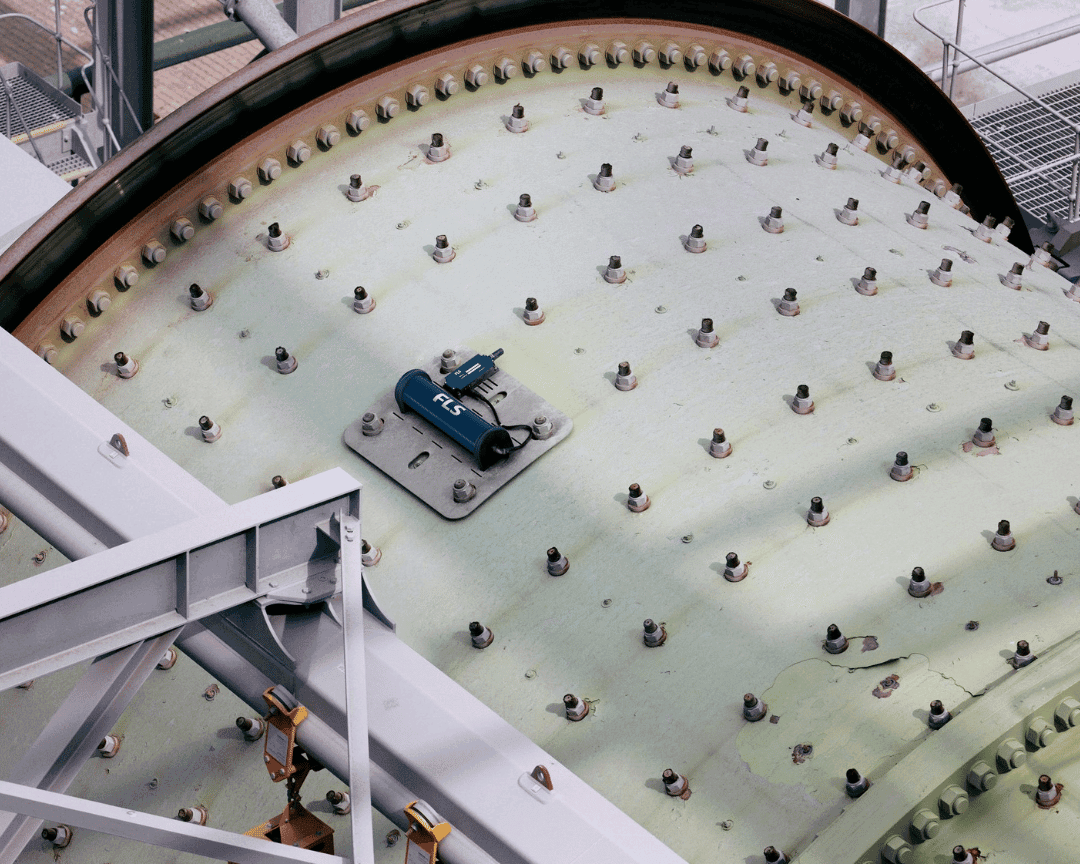

LoadIQ was installed on three milling lines, each with a 40 ft x 24 ft SAG mill for primary grinding. The smart sensor system reacts to changes in grinding conditions to maximise tonnage. As a result:

- Average throughput across the three mills increased 10%.

- 3-5% reduction in variability.

- 8% decrease in specific energy, equating to 9% decrease in energy per tonne copper produced (GJ/t Cu-eq).

With a head grade of 0.42% and copper price of USD 3.80 per pound, this increase in throughput resulted in higher revenue of USD 150 million over an operating period of 5,900 hours.

Operating costs and CO2e emissions per tonne were also reduced due to the reduction in energy consumption.