Technical suitability of KREBS pumps, cyclones, and valves

1. Typical applications

KREBS equipment handles abrasive slurries across various material processing applications, including:

- Sand and fines recovery

- Crushed stone washing and classification

- Frac sand processing

- Dewatering and desliming

- Dredging and transfer applications

2. Materials, footprint and installation

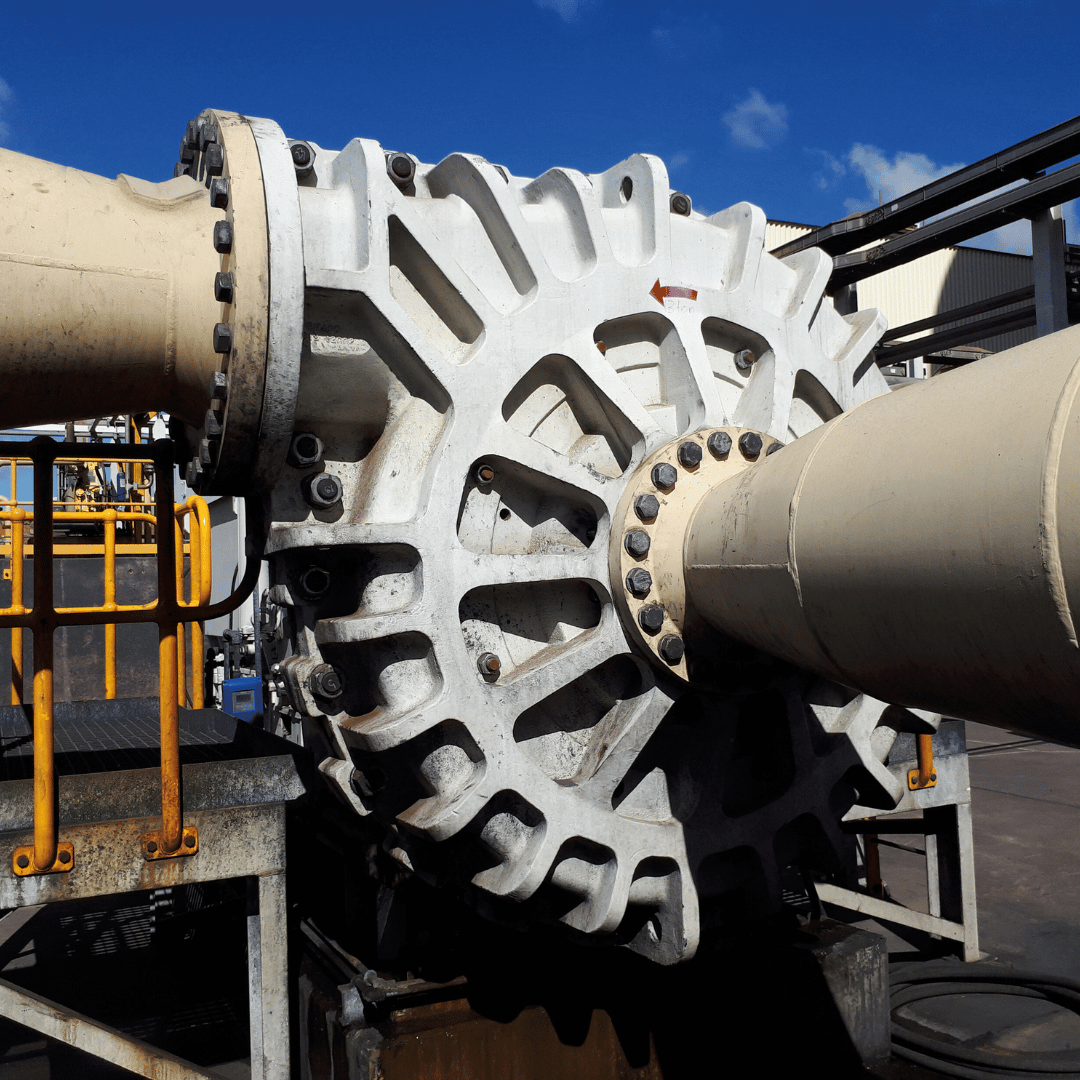

From casting to finished painted parts, FLS has the equipment and expertise to deliver the best material options to our customers. We offer a wide range of elastomers that can handle various chemicals, pH levels, concentrations, and temperature ranges, proprietary high-chrome irons specifically designed to provide outstanding abrasion and/or corrosion resistance, and tungsten carbide laser cladding for extended wear life in the most abrasive applications. Our material offering also includes a range of urethane liners, capable of operating at higher tip speeds and withstanding fine particle wear.

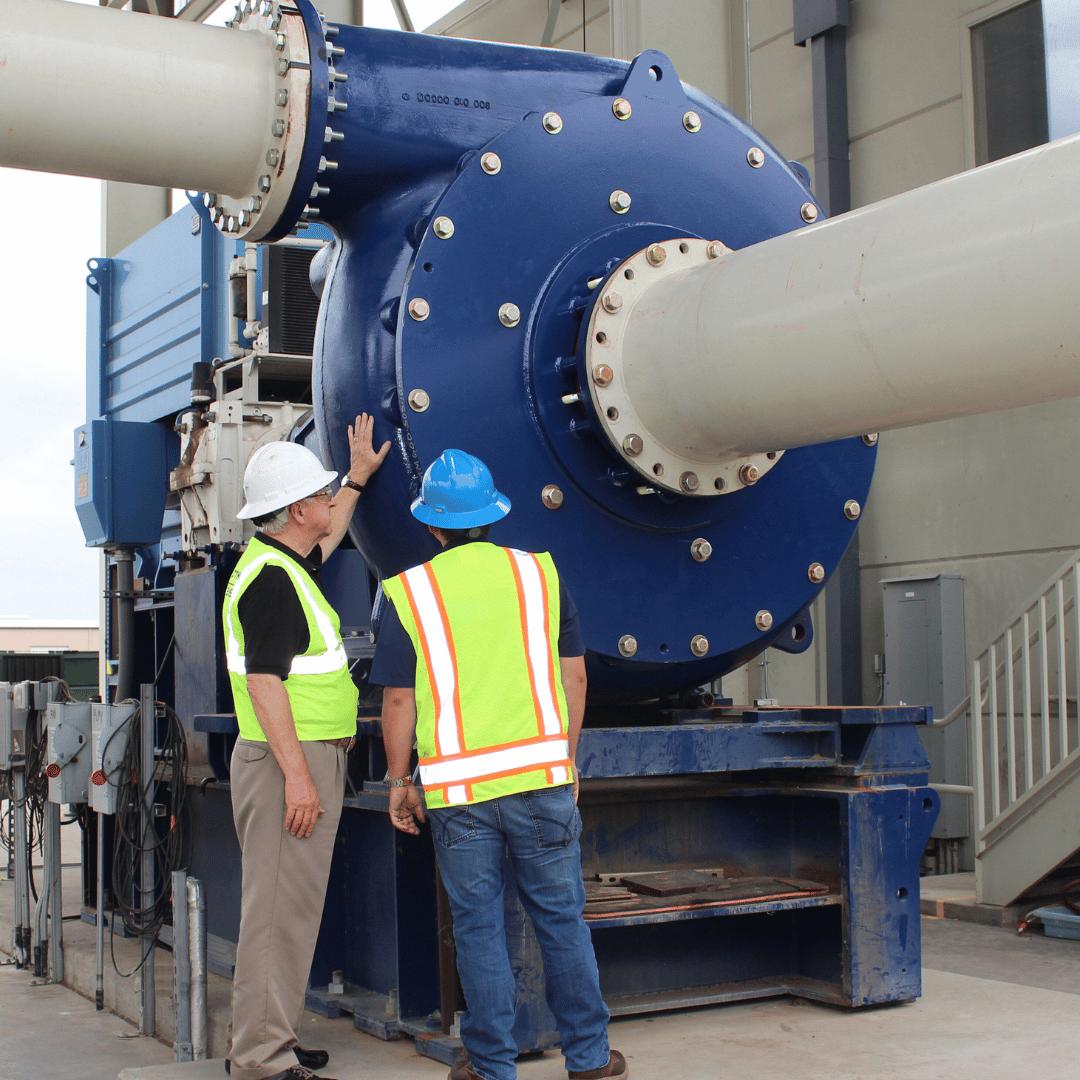

KREBS pumps and cyclones integrate into existing plant layouts with standard flange connections and mounting configurations. Split-case pump designs allow in-situ maintenance without disturbing piping connections. Cyclone manifold systems can be configured for single or multiple units depending on the required capacity and classification requirements.

3. Process integration

Cyclone systems typically receive feed from pump discharge, with underflow reporting to dewatering equipment or product stockpiles and overflow returning to upstream classification or settling ponds. Pump selection considers required head, flow rate, slurry characteristics, and operating point relative to Best Efficiency Point (BEP) to maximise wear life and minimise power consumption.