The UMD slurry pump benefits

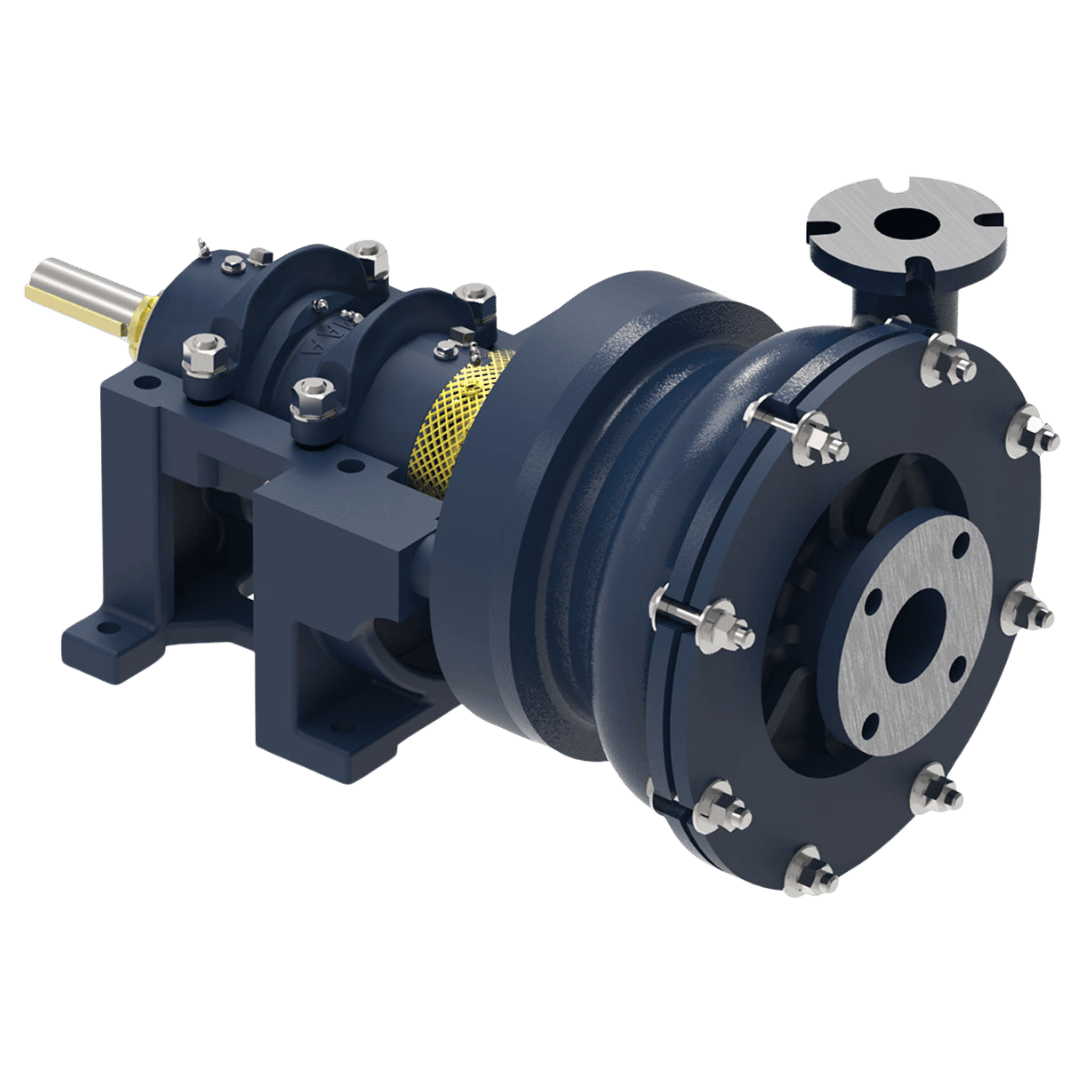

These design features deliver multiple benefits, including even and predictable wear for wet end parts and a 5% to 10% reduction in power consumption for the same head and flow. As a result, the UMD pump has been proven to reduce downtime, power, and maintenance costs when compared to conventional pump designs, and achieve lower cost-per-ton pumped.

The UMD pump is available in a range of interchangeable elastomer, alloy, and polyurethane liner materials and can handle flow rates of 200 GPM to 90,000 GPM (50-20,000m3/hr).

Versatile options: UMD-R and UMD-HP

In addition to the standard UMD pump, two alternate designs are available to meet specific application requirements: the UMD-R rubber-lined split-case pump and UMD-HP high-pressure pump.

UMD-R split-case rubber-lined pump

The UMD-R pump features a fully rubber-lined split-case design that is particularly suited to heavy-duty mill discharge applications where wide flow rates and/or corrosive agents are an issue. The thick rubber liners are available in a range of elastomer material options.

The UMD-R pumps utilises the same suction liner assembly, impeller and back liner components as the UMD unlined pump range.

UMD-HP: Handling high-pressure coarse tailings and hydrotransport

The UMD-HP pump is available for multi-stage, high-pressure coarse tailings and hydrotransport applications and features tie-bolt outer casing halves within which sits a large-diameter impeller. A thick chrome-iron casing with additional ribs supports the back and suction liners, which are available in a range of ultra wear-resistant materials for extended wear life in even the most abrasive applications.

Wear life extension: UMD pump success story

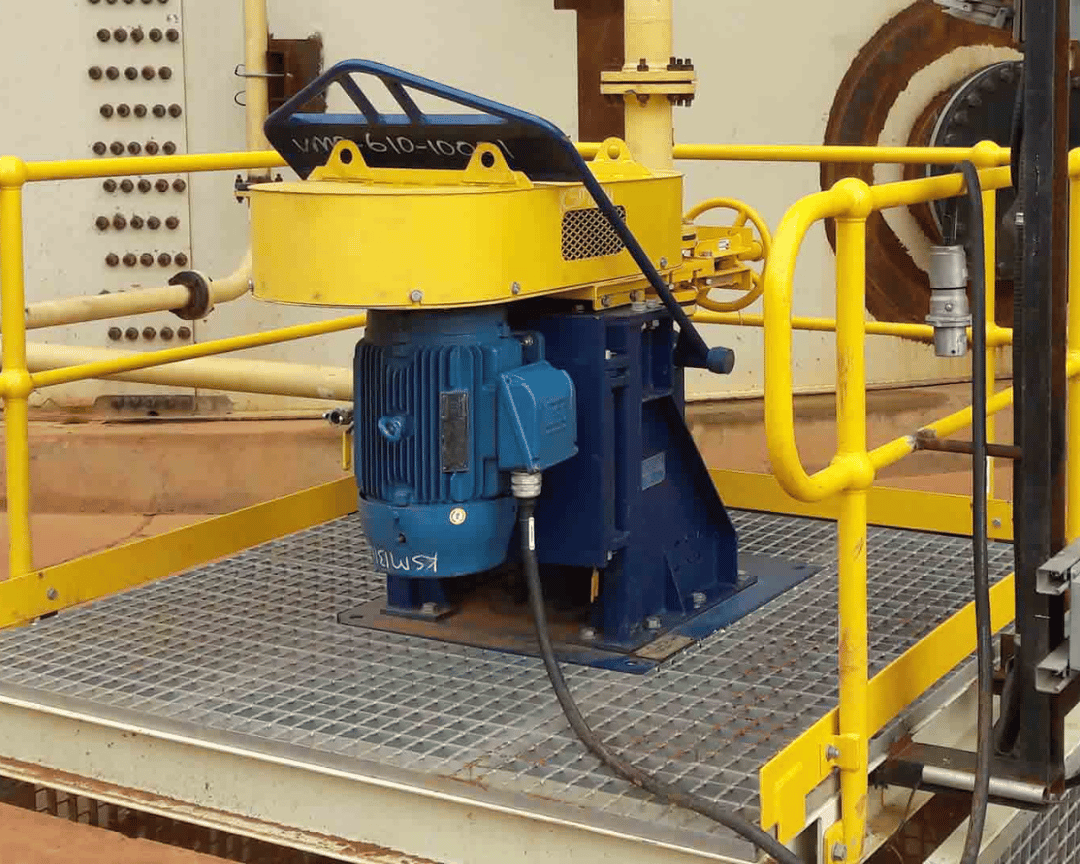

Demonstrating the advantages of the standard UMD design, a UMD pump was installed at a gold mine in Indonesia, which was looking to improve performance of its ball mill in the concentrator of a cyclone feed application. The facility processes 240,000 tons of ore per day and required frequent shutdowns to maintain performance.

A UMD 26x22 (650 x 550mm) was installed at the ball mill, with different suction liner and wear ring material combinations tested. After two trials, the new pump had already shown significantly extended wear life, with two different suction liner assemblies hitting the targeted wear life. The first more than doubled wear life compared the competitor; the second hit three times the wear life. The casing and impeller remained unchanged throughout both trials with the impeller now running more than 2.5 times longer than the competitor.